|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

|

|

#1 |

|

Registered User

Join Date: Jun 2016

Location: Novato, CA

Posts: 519

|

Rebuild in progress - can't turn crank?

1965 GMC 1000, rebuilding the 230. Ended up actually needing a new block due to a crack. The new block is cast with a 1968 model year but looks identical.

I have the crank and cam installed. Main bearings torqued to spec (65 ft lbs). Sticky assembly lube on everything (because I don't know any better). I can't turn the crank by hand and I just wanted a sanity check on this before I go any further. Sound right? Bearings are .010 over, new-to-me crank is supposed to be freshly ground to the same by a reputable shop. I tried putting bolts into the flywheel mounting holes on the crank and turning it with a screwdriver, to no avail. I recall when I was disassembling everything, I had a hard time turning the crank in this fashion as well, but it did move. Now it's not moving. I haven't tried my hardest but was worried about f-ing something up. All the caps are in order and the arrows are pointing forward. Tips/suggestions?

__________________

1965 GMC 1000 SWB Fleetside L6 230 - SOLD Thanks everyone for the help over the years. |

|

|

|

|

|

#2 |

|

Registered User

Join Date: Sep 2006

Location: San Francisco

Posts: 4,782

|

Re: Rebuild in progress - can't turn crank?

did you use plasti gauge to check clearance on the bearings?

__________________

"A man and his truck, what a beautiful thing" 65 Short Fleetside BBC 65 Long Fleetside 283 3 on the tree for now. my build thread http://www.67-72chevytrucks.com/vboa...d.php?t=259536 |

|

|

|

|

|

#3 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,674

|

Re: Rebuild in progress - can't turn crank?

I wouldn't go any futher....tear it down and find what's binding..start by removing the center mains 1 at a time leaving the ones on the ends..check to see if it'll rotate by hand with each cap removal..

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#4 | |

|

Registered User

Join Date: Jun 2016

Location: Novato, CA

Posts: 519

|

Re: Rebuild in progress - can't turn crank?

Quote:

With everything torqued back to spec, I can't move the crank literally with my hand on a counterweight (well maybe I could with greater effort but not "easy" like my camshaft spins), but I can turn the crank by putting bolts into the holes where the flywheel connects and turning it with a screwdriver for a lever. Does this sound right?

__________________

1965 GMC 1000 SWB Fleetside L6 230 - SOLD Thanks everyone for the help over the years. |

|

|

|

|

|

|

#5 |

|

Registered User

Join Date: Aug 2018

Location: Bronx, NY

Posts: 215

|

Re: Rebuild in progress - can't turn crank?

I don't know what kind of rear main seal you have, but loosening #6 might indicate that the seal, if it is a rope type two-piece is doing what it is supposed to be doing.

|

|

|

|

|

|

#6 |

|

Registered User

Join Date: Jun 2016

Location: Novato, CA

Posts: 519

|

Re: Rebuild in progress - can't turn crank?

Did not plastigauge it yet. How hard is it supposed to be to turn?

__________________

1965 GMC 1000 SWB Fleetside L6 230 - SOLD Thanks everyone for the help over the years. |

|

|

|

|

|

#7 |

|

Moderator

Join Date: Dec 2012

Location: ON, Canada

Posts: 2,181

|

Re: Rebuild in progress - can't turn crank?

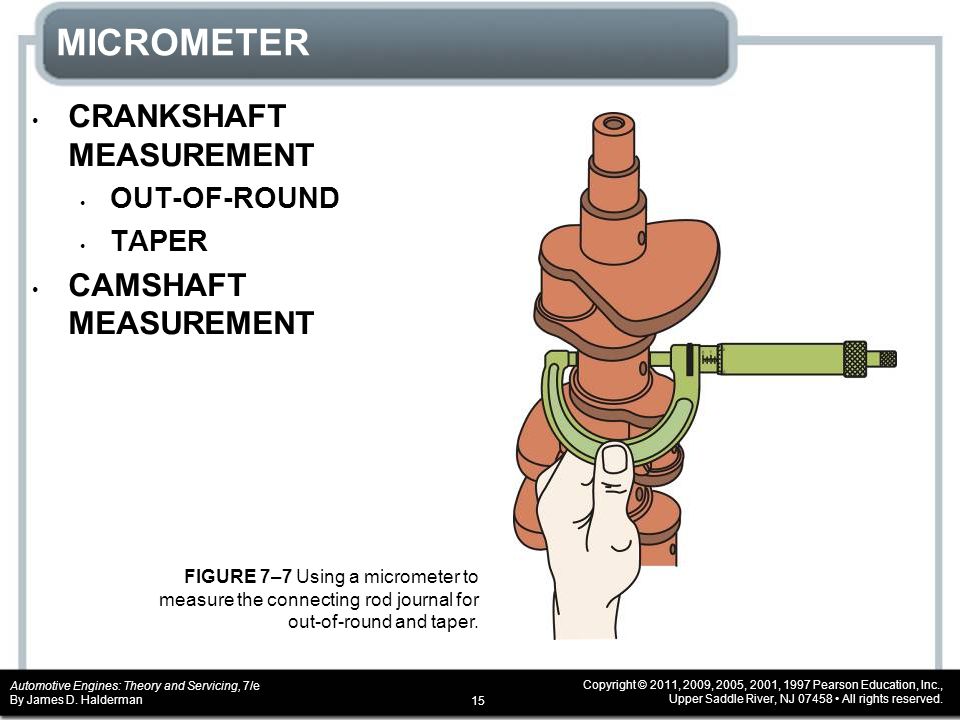

Pretty easy. Something's wrong. Get the mic on it, and do a plastigauge check.

|

|

|

|

|

|

#8 |

|

Registered User

Join Date: Sep 2006

Location: San Francisco

Posts: 4,782

|

Re: Rebuild in progress - can't turn crank?

No.. You should be able to turn it with your hand. Need to check clearances. You might get some resistance but not that much.

__________________

"A man and his truck, what a beautiful thing" 65 Short Fleetside BBC 65 Long Fleetside 283 3 on the tree for now. my build thread http://www.67-72chevytrucks.com/vboa...d.php?t=259536 |

|

|

|

|

|

#9 |

|

Registered User

Join Date: Jun 2016

Location: Novato, CA

Posts: 519

|

Re: Rebuild in progress - can't turn crank?

Okay I'll get some plasti gauge. But whats next if clearances are too tight? Drop another $60 on different bearings? Send my crank back to the shop and tell them **** doesn't fit?

__________________

1965 GMC 1000 SWB Fleetside L6 230 - SOLD Thanks everyone for the help over the years. |

|

|

|

|

|

#10 |

|

Senior Member

Join Date: Sep 2016

Location: Denmark

Posts: 309

|

Re: Rebuild in progress - can't turn crank?

Did you use oil on bearings?

|

|

|

|

|

|

#11 |

|

Registered User

Join Date: Aug 2011

Location: Shepherd, Texas

Posts: 83

|

Re: Rebuild in progress - can't turn crank?

I know a guy that had this issue. In this case the machine shop turned all the journals except one so when he put the oversized bearings on it would not turn.

|

|

|

|

|

|

#12 |

|

Senior Member

Join Date: Dec 2009

Location: Chester,California

Posts: 5,632

|

Re: Rebuild in progress - can't turn crank?

Your block may need align honed. Talk to the shop that you took it too; they should be able to help you.

__________________

1977 Chevrolet K10 SWB Project 350/4spd/np205 1977 Chevrolet K20 LWB 350/350/203 1991 4Runner 22RE 5 SPD Yanmar Tractor 3 Cyl Diesel |

|

|

|

|

|

#13 |

|

Moderator

Join Date: Dec 2012

Location: ON, Canada

Posts: 2,181

|

Re: Rebuild in progress - can't turn crank?

To clarify... two of us have said to mic/mike the crank. If you don't know what that means, let's help. Get and use a micrometer to measure each of the crank journals.

https://mobiloil.com/en/article/car-...the-bottom-end

|

|

|

|

|

|

#14 | |

|

Registered User

Join Date: Jun 2016

Location: Novato, CA

Posts: 519

|

Re: Rebuild in progress - can't turn crank?

Quote:

__________________

1965 GMC 1000 SWB Fleetside L6 230 - SOLD Thanks everyone for the help over the years. |

|

|

|

|

|

|

#15 |

|

Post Whore

Join Date: May 2015

Location: Alabama

Posts: 14,674

|

Re: Rebuild in progress - can't turn crank?

Take it back to the machine shop...they'll have all the proper tools to find out what's going on...

It could be wrong bearings..crank turned wrong,bore line...or whatever...but you should be able to turn it by hand with minimal resistance....even if you had rods and pistons on it you should be able to hand spin it..

__________________

Mongo...aka Greg RIP Dad RIP Jesse 1981 C30 LQ9 NV4500..http://67-72chevytrucks.com/vboard/s...d.php?t=753598 Mongos AD- LS3 TR6060...http://67-72chevytrucks.com/vboard/s...34#post8522334 Columbus..the 1957 IH 4x4...http://67-72chevytrucks.com/vboard/s...63#post8082563 2023 Chevy Z71..daily driver |

|

|

|

|

|

#16 |

|

Registered User

Join Date: Jun 2016

Location: Novato, CA

Posts: 519

|

Re: Rebuild in progress - can't turn crank?

The #2 cap and #6 cap, when torqued to spec (65 ft-lbs), cause me to not be able to turn the crank by hand. If I loosen these two, with everything else still torqued, it turns quite easily.

I plasti-gauged these two. As best I can tell, they are in spec, at 0.00125 (roughly halfway between .0015 and .001) I guess this indicates that I need to have the shop check and possibly align-hone the block? Is there something else that could be going on?

__________________

1965 GMC 1000 SWB Fleetside L6 230 - SOLD Thanks everyone for the help over the years. |

|

|

|

|

|

#17 | |

|

Registered User

Join Date: Aug 2018

Location: Bronx, NY

Posts: 215

|

Re: Rebuild in progress - can't turn crank?

Quote:

I've even heard stories of crankshafts getting warped by leaning them against something. They don't like it. Something about them turning up their nose at such rude treatment. Last edited by kazoocruiser; 11-18-2018 at 09:46 PM. |

|

|

|

|

|

|

#18 | |

|

Registered User

Join Date: Jun 2016

Location: Novato, CA

Posts: 519

|

Re: Rebuild in progress - can't turn crank?

Quote:

__________________

1965 GMC 1000 SWB Fleetside L6 230 - SOLD Thanks everyone for the help over the years. |

|

|

|

|

|

|

#19 | |

|

Registered User

Join Date: Aug 2018

Location: Bronx, NY

Posts: 215

|

Re: Rebuild in progress - can't turn crank?

Quote:

|

|

|

|

|

|

|

#20 |

|

Senior Member

Join Date: Jan 2011

Location: Hayes Va

Posts: 4,569

|

Re: Rebuild in progress - can't turn crank?

The only way to fix this correctly is to measure everything. To check the crank you need a 1" to 2" mic for the rod journals and a 2"to 3" for the mains. Borrow mics with the .0001 scale on them. Measure all the journals size, out of round and taper. Write down all your measurements and make sure it is with in spec. Next you will need a dial bore gauge. Put on the main caps with out the bearings and torque them to spec. Check the bores for size and out of round and verify they are in spec. Now repeat the process with the bearings in. The difference between the crank measurements and the bearing measurements is your true clearance. With this information you can get to the true issue. They could range from a poor grind to miss marked bearings. I don't use plastigauge as it only tells you what you have and not why.

Jimmy

__________________

60 to 66 Chevy and GMC window decals http://67-72chevytrucks.com/vboard/s...d.php?t=661131 Good friends, good food and a hotrod what else do you need? 1966 BBW long fleet Daily driver 1965 BBW short fleet Sold and going to a good home 1965 Suburban 2003 3500 Duramax 2005 Ultra Classic |

|

|

|

|

|

#21 | |

|

Registered User

Join Date: Aug 2018

Location: Bronx, NY

Posts: 215

|

Re: Rebuild in progress - can't turn crank?

Quote:

All of that is useful information, but only if the crankshaft doesn't have a warp in it. None of those measurements will pinpoint out of alignment main bearing journals. The crankshaft has to be tested on v-blocks or a lathe and measured for runout |

|

|

|

|

|

|

#22 |

|

Registered User

Join Date: Apr 2012

Location: Wisconsin

Posts: 3,329

|

Re: Rebuild in progress - can't turn crank?

.00125 to .0015 is not enough clearance. Should be .002-.0025. One thing I have to ask. When you put the main bearings in , did you put them in dry and super clean OR wet and oily against the block ?

__________________

IS IT an EATON or Chevrolet rear axle https://67-72chevytrucks.com/vboard/...d.php?t=843778 The hubcap thread http://67-72chevytrucks.com/vboard/s...d.php?t=702839 WANTED : 1963-1966 6 Cylinder Fan Shroud WANTED :1964-1966 PANEL TRUCK |

|

|

|

|

|

#23 | |

|

Registered User

Join Date: Jun 2016

Location: Novato, CA

Posts: 519

|

Re: Rebuild in progress - can't turn crank?

This contradicts what the GMC Maintenance Manual says for clearance, which shows 0.0003" - 0.0019".

Quote:

In any case, I dropped the block and crank off at the shop and they're going to take a look for me.

__________________

1965 GMC 1000 SWB Fleetside L6 230 - SOLD Thanks everyone for the help over the years. |

|

|

|

|

|

|

#24 |

|

Registered User

Join Date: Apr 2012

Location: Wisconsin

Posts: 3,329

|

Re: Rebuild in progress - can't turn crank?

All bearings need to be put in dry during assembly, I always cleaned with lacquer thinner before putting them in. They will get oil behind them to prevent rust on there own , have never seen rust behind a bearing on a rebuilt good running engine so I wouldn't worry about that. Ive seen engines assembled that guys couldn't move the crank where oil was put on the block and back of bearing during assembly. We ALWAYS measured the bearings in the block like PGSIGNS outlined above, then ground the crank to fit .I was a crankshaft grinder for 20plus years. .0003 or three tenths on the low end is guaranteed to fail as they're showing in that manual , even .001 will fail eventually. I would be at the high end minimum for main clearance but as I've said I still "like" .002-.0025 IMHO . GM on an assembly line to gain clearance or reduce clearance had a wide range of over and under bearings even for a standard ground crankshaft. I can pretty much guarantee GM never assembled an engine with .0003 to .001 clearances

__________________

IS IT an EATON or Chevrolet rear axle https://67-72chevytrucks.com/vboard/...d.php?t=843778 The hubcap thread http://67-72chevytrucks.com/vboard/s...d.php?t=702839 WANTED : 1963-1966 6 Cylinder Fan Shroud WANTED :1964-1966 PANEL TRUCK |

|

|

|

|

|

#25 |

|

Registered User

Join Date: Apr 2012

Location: Wisconsin

Posts: 3,329

|

Re: Rebuild in progress - can't turn crank?

To the comment above on the "bent crank" yes that's a great thing to check and is very important. However , just knocking a crank over isn't going to bend it if it was perfectly straight out of the machine. Would take a pretty good hit to bend it.

One other area that will cause the crank to not rotate is the radius of the journal , if the bearing comes in contact with the radius it wont move , look for shinny spots on the edge of the bearing and also tap the crank back and forth before torqueing the thrust bearing. The tapping of the crank like that aligns the bearing to the thrust surface of the crankshaft. That's your "end play"

__________________

IS IT an EATON or Chevrolet rear axle https://67-72chevytrucks.com/vboard/...d.php?t=843778 The hubcap thread http://67-72chevytrucks.com/vboard/s...d.php?t=702839 WANTED : 1963-1966 6 Cylinder Fan Shroud WANTED :1964-1966 PANEL TRUCK |

|

|

|

|

| Bookmarks |

|

|