|

|

|

#351 |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

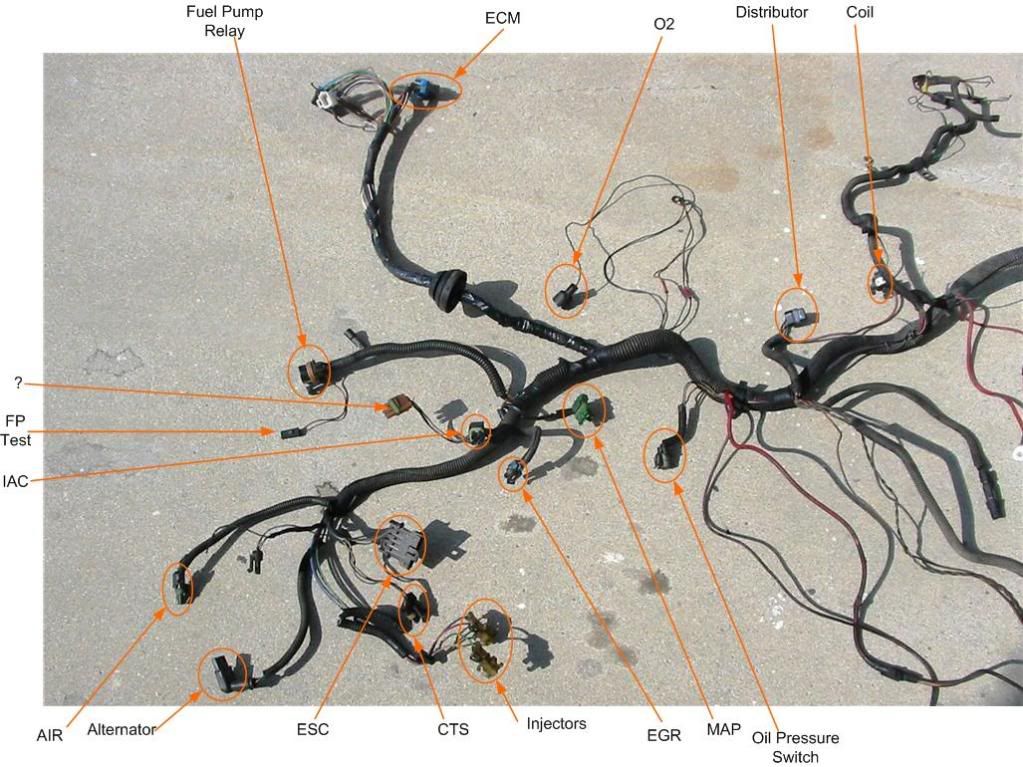

Re: Tbi swap build thread

'90 burban harness with connectors ID's. The only ECM related wiring that goes to the right is the set EST. Set EST is a single circuit (brown-white) to a single circuit connector. IMHO I would self contain all circuits directly connected to ECM in a stand alone harness (this is how after market harnesses are built). The alternator, power, starter, etc can be routed separately.

//RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

#352 |

|

Registered User

Join Date: Oct 2009

Location: ochelata, oklahoma

Posts: 8

|

Re: Tbi swap build thread

ok rf the underhood harness is gone on the 65 i junked it the wires were falling apart lol! now on the fuse block ive got one out of a 85 chevy truck i was going to use just to be safe becouse im sure the 65 isnt is mutch better shape then the underhood harness lol! there isnt really mutch to the 65 kinda nice lol just blower motor and lights! thanks jd

|

|

|

|

|

|

#353 |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

JD

Can you take couple of photos of that '89 fuse block. I did a lot of digging regarding engine compartment harness wires (fuse block) and some colors do not make sense. But here what you need to know (in a nut shell). GM uses red 10AWG for direct battery connected circuits. 10AWG Orange indicates is that circuit is fused battery circuit 10AWG Pink is ignition coil 10AWG Purple is starter solenoid. What kind of ignition switch do you have on 65???? Do you have P/N switch in your 65? Gauges, idiot light, etc??? This looks more like a custom wire harness job. With this in mind I would break this conversion into two (manageable) parts. First part would be a basic power circuits into the cab, to ignition switch and fuse block. Once that done, second part is to bring in ECM wire harness. There are couple wiring examples in this thread addressing similar problem. //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

#354 |

|

Curmudgeon of Poor Means

Join Date: Jan 2009

Location: Lubbock, Texas

Posts: 113

|

Re: Tbi swap build thread

I've been following this thread with interest as I'm going to convert my '82 C20 to TBI and maybe a 4L80E at some point, plus I'm already gathering parts to convert my '90 R3500 crew cab to a 4L80E...it is factory equipped with 454 TBI, but want to add 4L80E as if it were a '91...

RF, do you have any info with regard to the 4L80E? I'm pretty comfortable with the TBI side of things, but haven't had a 4L80E equipped truck to play with yet. Is the 4L80E controlled by the same ECM as the TBI, or is there a separate controller? I'm told that 91 up diesel trucks had a stand alone converter, but have been assuming they integrated the transmission control into the TBI on the 91 gas burners. Thanks, Travis |

|

|

|

|

|

#355 | |

|

Still plays with trucks

Join Date: Jul 2009

Location: Spokane, WA

Posts: 3,556

|

Re: Tbi swap build thread

Quote:

|

|

|

|

|

|

|

#356 | |

|

Still plays with trucks

Join Date: Jul 2009

Location: Spokane, WA

Posts: 3,556

|

Re: Tbi swap build thread

Quote:

|

|

|

|

|

|

|

#357 | |

|

Still plays with trucks

Join Date: Jul 2009

Location: Spokane, WA

Posts: 3,556

|

Re: Tbi swap build thread

Quote:

|

|

|

|

|

|

|

#358 | |

|

Still plays with trucks

Join Date: Jul 2009

Location: Spokane, WA

Posts: 3,556

|

Re: Tbi swap build thread

Quote:

Look for a 94 or 95 donor and you will get the best PCM for the job the 16197427. The diesel did use a stand alone controller for a couple years. I believe it was 91 to 93 but since you have a TBI motor you might as well run it all off the faster 16197427 PCM and get a better running engine too. |

|

|

|

|

|

|

#359 |

|

Curmudgeon of Poor Means

Join Date: Jan 2009

Location: Lubbock, Texas

Posts: 113

|

Re: Tbi swap build thread

Thanks; that's the kind of info I was looking for. I just bought a '91 3/4 ton with 454 and 4L80E to use as a donor; how big a deal is the 94-95 PCM? I'm quite pleased with the way the 90 runs, so assumed I'd be happy with the 91 model. What are the advantages to the 94-95?

Travis |

|

|

|

|

|

#360 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

Updated photo  //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#361 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

While on this subject both XDF and ADS configuration files are available from Moates for TurnerPro covering this PCM. My next conversion project (TBD) will probably use one of the these P4 PCMs. //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#362 |

|

Curmudgeon of Poor Means

Join Date: Jan 2009

Location: Lubbock, Texas

Posts: 113

|

Re: Tbi swap build thread

What about the pinouts on the connectors? Are they the same; that is, can the later 7427 PCM be substituted? Since my conversion is going to be from a 88-up body style into a square body, I'll have to reassemble the TBI harness anyway. I'd assume all or most of the sensor connectors and colors are the same?

Thanks for the info; I'm glad to be learning. Travis |

|

|

|

|

|

#363 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

Real credit goes to Fast355 on TGO for doing grant work. You can find it here: http://www.thirdgen.org/techboard/tb...rting-tbi.html This is the basic list (original can be found on above mentioned TGO thread) ================================================= I have had multiple people ask about re-pinning their earlier TBI cars/trucks to use the latest PCM. So here is the result. Information regarding the swap. PCM Swap/Tuning Notes 8746/6965/7747/299 to 427 Truck PCM (Car showed, Trucks VERY similar) Old Pin----New Pin-----Color------------Function A1--------F6----------GRN/WHT-------Fuel Pump Relay Control A3--------F16---------DK GRN/YEL-----Charcoal Canister Purge Solenoid A4--------E1----------GRY-------------EGR Control A5--------E6----------BRN/WHT--------Service Engine Soon Light A6--------E15---------PNK/BLK---------Ignition Feed +12VDC A7--------(1*)--------TAN/BLK---------TCC/Shift Light A8--------F9----------ORN------------Serial Datastream A9--------A14---------WHT/BLK-------Diagnostic Test A10-------F13---------BRN------------Vehicle Speed Signal A11-------B3----------BLK------------Sensor Ground A12-------A1----------BLK/WHT-------ECM Ground 1 B1--------E16---------ORN------------Battery +12VDC B2--------B12---------TAN/WHT-------Fuel Pump Signal B3--------A5----------BLK/RED--------EST Ref Low B5--------A4----------PPL/WHT-------EST Ref High B6--------?-----------PPL-------------VATS(2*) B7--------(3*)---------BLK-------------Knock Sensor B8--------E12---------LT BLUE--------A/C Clutch Signal B10-------E5----------ORN/BLK--------Park/Neutral Switch C1--------(4*)-------BLK/PNK---------A.I.R. Converter Solenoid C2--------E7---------BRN-------------A.I.R. Port Solenoid (Diverter in trucks) C3--------A7---------LT GRN/BLK------IAC "B" Low C4--------A8---------LT GRN/WHT-----IAC "B" High C5--------A3---------LT BLU/WHT-----IAC "A" High C6--------A6---------LT BLU/BLK------IAC "A" Low C7--------(5*)-------LT BLU-----------High Gear Switch (In Auto Trans) C8--------(6*)-------LT BLU-----------Power Steering Pressure Switch C9--------(7*)-------PPL/WHT---------Crank Signal C10-------B8---------YEL--------------Coolant Temperature Signal C11-------B13--------LT GRN----------MAP Signal C12-------B9---------Tan-------------MAT Signal(8*) C13-------A15--------DK BLUE--------TPS Signal C14-------E14--------GRY------------5 Volt Reference C15/D14--A9---------DRK GRN--------Injector "2" Control C16------E13--------Orange----------Battery (Inputed in place of Brake Switch for TCC to function) D1-------A2---------BLK/WHT--------ECM Ground 2 D2-------B4---------PPL-------------MAP Sensor Ground D4-------F11--------WHT------------EST Signal D5-------B2---------TAN/BLK--------EST Bypass D6-------A12--------TAN------------O2 Sensor Ground D7-------A10--------PPL-------------02 Sensor Signal D15/D16--A16-------DK BLUE---------Injector "1" Control Swap Notes (1*)= Use E2 for a shift light on a manual transmission or E10 for the TCC on an Automatic (2*)= Supported by the PCM if optioned in the Prom on an UNKNOWN pin (3*)= A.) Wire like 1995 P30 Step Van, ESC Module output to B7 (3*)= B.) Wire like 1995 C10 Truck, Bypass ESC (Blue to Brown) and use Late TBI/TPI 305/350 Knock sensor (4*)= Air injection into converter not used on trucks, but PCM has several other un-used outputs (Tuning Valve, Idle Kicker) (5*)= Not Used by PCM (I like to leave the small connector in place and pin in unused wires) (6*)= Supported by PCM if optioned in the Prom on an UNKNOWN pin (1994-1995 2.2 S10 Wiring Diagram anyone?) (7*)= Not used by PCM, Remove 3 amp "CRANK" fuse from fuse box and store in small connector) (8*)= Supported by the PCM, but functionality will need to be enabled in the Prom 6965 ONLY- Will have a NC relay that the computer grounds to shut-off the A/C compressor when the engine is heavily loaded. The A/C will work either by removing the wire all-together, or connecting it to pin E3 (A/C Cut-Off or CPI Tuning Valve output) I would also like to mention that the orange Serial Data wire needs to be relocated from the top row, Pin "E" to the lower row, Pin "M". You will also need to scan the vehicle like a 1993-1995 G-Series Van, C-Series Truck, S-Series Blazer, etc with Auto transmission. =====================================================

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#364 |

|

Registered User

Join Date: Apr 2009

Location: Arvada, Colorado

Posts: 84

|

Re: Tbi swap build thread

Just to be clear...

I can eleminate the EGR if I get a new mailorder PROM burned and I should run fine? There is not an older (vintage) EGR valve that will work on my setup? I think that the older EGR valves, which would fit on the new intake, are for carburated engines and will not work with TBI? |

|

|

|

|

|

#365 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

The answer is yes. You can install EGR block off plate and get a mail order chip that disables EGR function. ECM will run just fine without throwing trouble codes. On my 75 I did just that - simply because my 3/4 ton did not had EGR to begin with and running EGR tends to lean out mixtures at part throttle. For 75 HD carbed applications EGR was outside the scope of emission certifications - as HD application did not have cats installed! In grand scheme of things EGR function reduces NOX levels and improves mileage - which is good all around. Getting EGR to work will take research and some effort. You should be able to use carbed EGR with TBI. You'll need EGR control solenoid which acts as on/off vacuum switch controllable by ECM. Look for early 80's EGR from 350 Impala - compare its flange to the gasket you have on hand. Edelbrock 3701 covers pre 86 heads - which leads me to think that most pre 86 EGR valves should work. //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#366 |

|

Registered User

Join Date: May 2009

Location: Space City! (TX)

Posts: 46

|

Re: Tbi swap build thread

Been awhile since I lurked here or posted on this thread (my $200 junk yard '87 tranny for ECM compatibility quit shifting to OD, so the truck has been sitting), but reading the recent posts, I am surprised that RF hasn't mentioned the other option of the Flash EBL, which replaces the PROM with flash memory (think zip drives or digital camera memory), allowing you to flash updated programs to the ECM instead of having chips burned. RF and I both use the Flash EBL ECM and I find it to be a simple and powerful upgrade that I consider well worth the price given the steep learning curve to program and/or burn PROMS (or the hassle and on-going expense of data logging and sending files to someone who burns chips until you get it right).

The Flash EBL also comes with an optimization routine that simply data logs and suggests a new program based on the data it gets and that takes about 1 second to flash to your ECM. After 5 or 6 optimizations, you won't believe how well your truck runs (or the mileage you get - my 82/85/87 C20 long bed was up over 30% compared to the carb!). My truck ran real rich after I got my TBI conversion done using stock parts and ECM from an 87 suburban C10 and I attributed it to excessive fuel pressure, which the Flash EBL compensates for (simple spreadsheet table you load with actual fuel pressures when first starting the program). I also run early non-vortec heads and an older RV cam and the Flash EBL still makes this "mutt" of 20+ year old parts run as reliably and well as something built in the last five to ten tears (really low emission rates at my last smog test too!). The Flash EBL also helps with disabling codes or modifying simple things in the program. For example, I had problems with intermittent ESC codes being set and I re-programmed (i.e., disabled) the timing retard using TunerPro and flashed the modified program to my Flash EBL ECM until I got around to finding the bad ground in the harness. After I fixed the wiring, it was simple to re-enable the timing retard for ESC and re-flash the ECM back to stock specs. I am sure this approach would work similarly for the no EGR issue Pancake has - and I bet it would do a good job compensating the fuel delivery program for decent fuel mileage even without the EGR (I have no date to prove this, but this my guess). Finally, the EBL Flash has a number of add-on programming enhancements not normally found in the stock ECM -see their web-site to see these. Downside is cost - $350 for the DIY model and you need a laptop to run the TunerPro and Flash EBL software (I use a 10 year old P3 running Windows 98 with great success). DISCLAIMER: I have absolutely NO vested interest in Dynamic EFI - I bought and paid for my Flash EBL at full retail with my own $$ and am simply a satisfied customer (and happy camper with the outcome). Frankly, it was one of the best mods/decisions I made when I did my TBI swap. Sorry for the "sales pitch", but I wanted to let others know that there are some nice (albeit kinda costly) alternatives to getting chips burned that also open up other possibilities. Good luck with your swaps. Mark |

|

|

|

|

|

#367 | |

|

Still plays with trucks

Join Date: Jul 2009

Location: Spokane, WA

Posts: 3,556

|

Re: Tbi swap build thread

Quote:

My biggest problem is that I am going to run a 4L80E and none of the ECM's he can modify can control it. I can always run a piggyback PCM or diesel trans controller but I would like to have it all in one. |

|

|

|

|

|

|

#368 | |

|

Registered User

Join Date: May 2009

Location: Space City! (TX)

Posts: 46

|

Re: Tbi swap build thread

Quote:

When an ECM is used on any engine and/or in any vehicle other than what it was originally installed (or at least a very close facsimile), the ECM will likely need to be re-programmed to run as good as it could/should. This is especially true for used ECMs installed on engines with different manifolds, heads, cams, headers, emission equipment, and/or fuel pressure than the original engine the ECM came from. So, re-programming TBI ECMs is pretty commonly needed and has two options I am aware of: (1) custom PROMs and (2) Flash EBL. The advantages of custom PROMS are lower apparent cost, but this can be off-set by the usual need for several iterations of data logging and analysis, re-programming, and re-burning PROMs (not to mention the hassle of removing and disassembling the ECM and swapping PROMs). Custom PROMs can also be swapped from one stock ECM to another in case one ECM fails. Disadvantages include (1) relying on someone else to burn chips (@ $50-100 per re-burn?) and the time for this to be done or (2) learning to program and burn chips yourself (burners are ~$150-200?). The Flash EBL is not a "custom" ECM, but a modified one with the modifications being the replacement of the PROM with flash memory (think digital camera cards/sticks, or zip drives) and installation of a serial port to allow communication with the flash memory. It's advantages include the simple self-optimizing software, being able to quickly and repeatedly DIY reprogram the ECM, and moving the piggy back board from one ECM to another if/when the ECM fails. For you guys that need to get your truck smog tested, the Flash EBL optimized programming also allows me to pass with flying colors even without cats (it was always borderline with the carb). Like a failed stock ECM with a custom PROM, a failed Flash EBL ECM can be replaced by a stock ECM to get running again (although not optimally if you have engine mods that the stock programming isn't expecting). If/when the Flash EBL ECM fails, you also have the advantage of having the optimized/customized program on your hard drive (I also keep mine backed up on a zip drive), making getting a custom PROM for the stock ECM a cinch. FWIW, I bought the "deluxe" Flash EBL with the flash memeory already installed in a used ECM and kept my stock ECM as a spare (and while I haven't done it, I could easily get a custom PROM with the optimized programming for the stock ECM) As an example of where quick DIY re-programming helped me out, I had an intermittent ESC problem that was causing the ECM to retard timing when there was no actual pre-detonation knocking. So, I simply used TunerPro to disable the spark retard tables and re-flashed my ECM to allow my truck to run properly until I had time to diagnose the ESC problem. After I diagnosed the ESC to a bad ground, I then re-flashed my ECM with the original programming. As for the 4L80E, the $200 junk yard '87 700R4 that I got from the same donor vehicle as the TBI system to ensure proper ECM control of the torque converter lock-up started not staying in OD when hot this past summer after two years of reliable service (not bad for $200 IMO). Thus, as I have a heavy duty 82/85/87 "mutt" C20 long bed with tommy lift, loaded tool boxes, 1 ton max-loader springs, Class V receiver hitch, etc., that I use for hauling and towing heavy crap, I looked hard at the 4L80E to replace the 700R4. Due to the ECM incompatibility and/or add-on control issues/problems you mentioned with the 4L80E, I ended up going with a heavy duty 700R4 designed/built for towing. Since this unit (including core, shipping, and a new torque converter) is about the same cost as a properly rebuilt "plain-jane" 4L80E, perhaps you should consider this route if you want "one box" compatibility (like I did). Good luck with your project and TBI swap! Mark Last edited by brontotx; 10-28-2009 at 03:57 PM. |

|

|

|

|

|

|

#369 | |

|

Still plays with trucks

Join Date: Jul 2009

Location: Spokane, WA

Posts: 3,556

|

Re: Tbi swap build thread

Quote:

I have had two ECM's physically break the board mounts so the internals were coming in contact with the case and one I could not identify why it stopped working but I would guess it was vibration damage too. All I had was limp home mode. Our roads are pretty bad up here in the winter and pretty much all the time so potholes and ruts give the ECM's a good beating. In two cases I had modified chips in them on G1 adapters and all I had to do was put the G1 with modified PROM onto the new ECM to get back on the road. One was completely stock. Being able to tune it on the spot so quickly is a very nice feature though. Do I understand this correctly that you can burn the optimized program from the EBL on a chip to use in the stock ECM as a backup part in case the EBL failed? If that is the case then it is not such a big deal to have the modified ECM. Keep a spare ECM ready to go with the other road side repair parts if you are going on a trip. A heavy duty 700R4 could do nicely but I all ready have the 4L80E, the 5.7 TBI PCM that came in the vehicle with it and a rebuilt TBI 350 upgraded with the Vortec truck hydraulic roller cam setup so I am going to stick with what I have. All I really need are the transfer case adapter parts and a column shift steering column to match. I considered running it as 2-WD until I found the parts to do the transfer case adaptation. |

|

|

|

|

|

|

#370 | |

|

Registered User

Join Date: May 2009

Location: Space City! (TX)

Posts: 46

|

Re: Tbi swap build thread

Quote:

I never suggested re-soldering a board on the side of the road as something one would/should try. The point I was trying to make is that a stock ECM plugged back in if/when the EBL failed should get you running (albeit not optimized) to get you home where one could undertake the soldering. My apologies if I wasn't clear. If I already had a 4L80E, I would have made the same decision as you to try and find a way to make it work. I was going to have to buy something no matter what and decided to keep it stock, but beefed up a tad. Good luck! Your mention of vortec heads is also interesting as I am looking to swap some vortecs onto mine - while more power is the main driver, the ability to re-optimize the ECM programming using the EBL is like icing on the cake. Mark |

|

|

|

|

|

|

#371 |

|

Still plays with trucks

Join Date: Jul 2009

Location: Spokane, WA

Posts: 3,556

|

Re: Tbi swap build thread

My motor is actually just a freshly rebuilt TBI motor with the hydraulic roller cam setup form a Vortec motor retrofit into it. I had the heads but didn't want to spend the money to get a Vortec TBI intake manifold so I used them in a trade for some parts I needed. The extra power from the heads would have been nice though.

|

|

|

|

|

|

#372 | |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: Tbi swap build thread

Quote:

Thanks for kind words - I actually run EBL, Flash based converted ECM in my truck. I gave up on swapping chips long ago. When I first started with EFI tuning I started by burning my own chips. This got old after about a week. Then came in circuit emulator (romulator). This was a step in right direction, but getting and dealing with 160 baud ALDL data was tooooo slow. EBL was next. The 7427 uses a very fast micro which even C3 EBL may not keep up with. The jury is still out on this experiment. I use EBL + Zeitronix wideband O2 with Tuner-Pro RT to tune my combo. However, due to many commitments are I have not been able to get top end performance. At this stage I am wrestling with a lot false knock due to resonating exhaust system Delta 40's are getting loud at about 2100 RPM! In a little free time that I have I look at other EFI controllers for ideas and cost-benefit analysis. The latest version of Megasquirt has been on my target list for while, but I have about dozen GM ECMs of various flavors which allows for plenty of experimentation. //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

|

#373 | |

|

Still plays with trucks

Join Date: Jul 2009

Location: Spokane, WA

Posts: 3,556

|

Re: Tbi swap build thread

Quote:

|

|

|

|

|

|

|

#374 |

|

Curmudgeon of Poor Means

Join Date: Jan 2009

Location: Lubbock, Texas

Posts: 113

|

Re: Tbi swap build thread

Is the 7427 not compatible with a 4L80E? I musta misunderstood?

Travis |

|

|

|

|

|

#375 | |

|

Still plays with trucks

Join Date: Jul 2009

Location: Spokane, WA

Posts: 3,556

|

Re: Tbi swap build thread

Quote:

I just got off topic a little and was talking about the MPFI ECM used with the TPI systems not being able to run the e-trans. Sorry for the confusion. Some guys have figured out a physical modification to do to the 7427 TBI PCM so it will fire the injectors in what they call port fuel mode so it can run an MPFI system smoothly. |

|

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|