|

|

|

#1 |

|

Registered User

Join Date: Oct 2011

Location: Houston Texas

Posts: 266

|

Finally

Alright so after a long week i finally got my clutch i took everything apart got the trans, bell housing, old clutch and flywheel off i was able to take all the grease and junk off of them and painted them a nice chevy orange

.... wasn't able to install the new clutch because i came into a couple problems ...... first off i was told that i need to turn the flywheel but couldn't find a shop open on this fathers day Sunday, secondly my rear main seal is leaking i wanted to replace it but later found out i have to remove the oil pan to put in the two piece seal.. im wondering is it possible to maybe replace the two piece seal with a one piece? and if i can remove the pan without taking out the engine? also i read that normally these seals start leaking when your main bearings are worn is this true and could that be the reason to the knocking sound my engine makes? i noticed that when my harmonic balancer rotates it looks kind of wobbly i don't know if this could also be a sign of worn bearings? .... wasn't able to install the new clutch because i came into a couple problems ...... first off i was told that i need to turn the flywheel but couldn't find a shop open on this fathers day Sunday, secondly my rear main seal is leaking i wanted to replace it but later found out i have to remove the oil pan to put in the two piece seal.. im wondering is it possible to maybe replace the two piece seal with a one piece? and if i can remove the pan without taking out the engine? also i read that normally these seals start leaking when your main bearings are worn is this true and could that be the reason to the knocking sound my engine makes? i noticed that when my harmonic balancer rotates it looks kind of wobbly i don't know if this could also be a sign of worn bearings?

__________________

"So she said, "Either I go or the truck goes!"....Hmm, I wonder what she's doing these days?" |

|

|

|

|

|

#2 |

|

Registered User

Join Date: Oct 2011

Location: Houston Texas

Posts: 266

|

Re: Finally

- -

__________________

"So she said, "Either I go or the truck goes!"....Hmm, I wonder what she's doing these days?" |

|

|

|

|

|

#3 |

|

Registered User

Join Date: Oct 2011

Location: Houston Texas

Posts: 266

|

Re: Finally

also painted the water pump fan

honestly i think i got a little to carried away with the orange

__________________

"So she said, "Either I go or the truck goes!"....Hmm, I wonder what she's doing these days?" |

|

|

|

|

|

#4 |

|

Registered User

Join Date: Apr 2010

Location: sacramento ca.

Posts: 1,038

|

Re: Finally

Looks like the parts cleaned up very well and paint looks good! It is also nice to see that you asked for information over a period of time listened to the answers and then dove in head first, that my friend is admirable and the best way to learn! im not a engine expert by no means, but since you say your harmonic balancer looks to be wobbling, and you have everything apart and the trans separated, see if you can pull or push the crank back and forth at all, I had a (sbc v8) that had some worn bearings and you could physically move the crank back and forth in the block around 3/8 of a inch which you shouldnt be able to do......just something you might want to try...good luck!

__________________

Timmy D. "What that grinding noise?Don't worry about that it will eventually clearance itself!" 1966 chevy c10 Build Thread:http://67-72chevytrucks.com/vboard/s...d.php?t=485977 1954 ford customline H.A.M.B 54 Build Thread:http://www.jalopyjournal.com/forum/s...d.php?t=622142 |

|

|

|

|

|

#5 |

|

Registered User

Join Date: Apr 2012

Location: Cambridge, Ontario, Canada

Posts: 1,771

|

Re: Finally

Hey Tony

The harmonic balance should absolutely not be wobbly, maybe the bottom pulley is loose, or bent. You really need to figure out the harmonic balancer, and remedy your rear main seal issue before you put anything back together. I would recommend that you get a shop manual, probably $30.00, and google/youtube "rear main seal replacement" (try a few different word combinations) to get some idea of what you are getting into. Also go to your local parts jobber, usually a guy or three there who have been there done that, and will make sure you get ALL of the bits and pieces you will need. I have to think though that you have progressed far enough at this point that removing the engine for the balance of this repair may make the job easier. Wish I were there to help!

__________________

Craigerrr My build thread, CRGRS 66 Winter Build: http://67-72chevytrucks.com/vboard/s...09#post5638709 |

|

|

|

|

|

#6 |

|

Registered User

Join Date: Apr 2012

Location: Cambridge, Ontario, Canada

Posts: 1,771

|

Re: Finally

here is a link to a video for changing the rear main seal (believe it is a series of videos), guy seems to be taking his time, offering a lot of explanation. It is for a jeep inline 6, so not a quote unquote step by step for you, but it will give you some idea of the process. I am pretty certain in looking at things that your oil pan will not come off with the engine on the mounts... the crank shaft and the cross member (I believe) will be too close together. You will notice the jeep does not have a cross member, and this is because it will have strut suspension. The steering linkage drops on the jeep when he sets the frame on axle stands. I will repeat that the shop manual is something you need to get your hands on (LMC/Classic Parts etc.)

Keep us posted buddy

__________________

Craigerrr My build thread, CRGRS 66 Winter Build: http://67-72chevytrucks.com/vboard/s...09#post5638709 |

|

|

|

|

|

#7 |

|

Registered User

Join Date: Apr 2012

Location: Cambridge, Ontario, Canada

Posts: 1,771

|

Re: Finally

the link I mentioned

__________________

Craigerrr My build thread, CRGRS 66 Winter Build: http://67-72chevytrucks.com/vboard/s...09#post5638709 |

|

|

|

|

|

#8 |

|

Registered User

Join Date: Feb 2012

Location: Jacksonville, Florida

Posts: 24

|

Re: Finally

I agree with the above posters that a wobbly balancer is bad. It could be the rubber ring is failing (pretty common on those old ones). The other suggestions are good too. As for the rear main seal, converting to one piece is not an option. The oil pan does have to come off to replace the seal but you have come this far....go for it! I think the pan can come off with the engine installed, IIRC. The rear seal could leak and the bearings be fine; no direct correlation between the two. A good sign of worn bearings is oil pressure (near zero at idle and lower than normal at speed). You say there is "knocking" from the engine. Is the noise down low? Or up on top? How many miles and do you know any history of service? Could be several options.... As for the clutch, replace the pilot bearing/bushing in the crank too (from your pix, looks like you took it out already). It may or may not come with the clutch kit but replace it in any event. Keep us posted and good luck.

|

|

|

|

|

|

#9 | |

|

Registered User

Join Date: Apr 2012

Location: Cambridge, Ontario, Canada

Posts: 1,771

|

Re: Finally

Quote:

__________________

Craigerrr My build thread, CRGRS 66 Winter Build: http://67-72chevytrucks.com/vboard/s...09#post5638709 |

|

|

|

|

|

|

#10 |

|

Registered User

Join Date: Oct 2011

Location: Houston Texas

Posts: 266

|

Re: Finally

im really thinking bout painting the truck blue and have orange to go with it

........ ill make sure to check the crank tomorrow to see if it moves... also if changing the bearings does the crank need any type of machining? and if so would i have to machine any thing else? ........ ill make sure to check the crank tomorrow to see if it moves... also if changing the bearings does the crank need any type of machining? and if so would i have to machine any thing else?Ill make sure to look into the shop manual and most of the auto parts places ive been to its mainly young folks that know almost nothing about these old trucks its kind of sad I have the engine hoist just need to buy a strong enough chain so lifting the engine to do the repair should be easy and thanks for the link these videos really help you when it comes to doing something you have never done before I have the oil pressure gauge its just not hooked up i might need help with that later on when i get it running again though the noise is normally down low but sometimes you can hear it up high the sound comes and goes but when i put some 40w it helped a lot the sound wasn't so constant as before so my plan is when i do an oil change ill probably use all 40w to help with that knock this is the clutch kit i got from my boss hopefully it comes with everything i need   also here is a video from a while back when i first asked about the noise, you can hear the knocking and at one point you can see the harmonic balancer. you cant really see that it wobbles but it does ...... wished i could make a new video but honestly i dont know how to turn on the engine without the bell housing and starter attached

__________________

"So she said, "Either I go or the truck goes!"....Hmm, I wonder what she's doing these days?" |

|

|

|

|

|

#11 |

|

Registered User

Join Date: Oct 2011

Location: Houston Texas

Posts: 266

|

Re: Finally

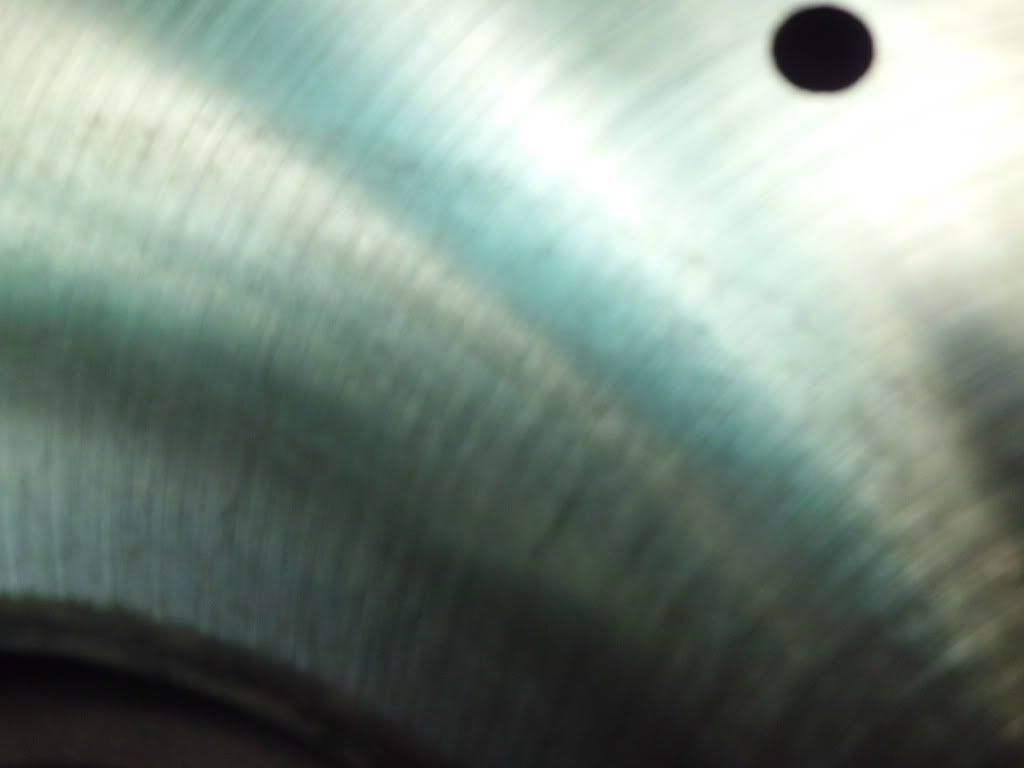

Also should i take my fly wheel to get it turned or is it ok how it is?

__________________

"So she said, "Either I go or the truck goes!"....Hmm, I wonder what she's doing these days?" |

|

|

|

|

|

#12 |

|

Senior Member

Join Date: Oct 2009

Location: Godley, TX

Posts: 17,975

|

Re: Finally

i would submit that you probably have a bent pulley, not balancer. if the balancer were wobbly, that thing wouldn't run that smoothly. (But, DO inspect the rubber parts of the damper)

As for the flywheel, it must be instepcted for heat cracks. They would be visible - if you look close and see any striations, or hairline cracks, or major heat damage, don't mess with it and replace it. If you do not see any of those, get it re-surfaced at a minimum. Doesn't cost much, maybe $25-30 at most machine shops. Concur with the comment above that a rear main seal leak is no indication of bearing wear. It's just an indication that the seal is torn. I'll tell you, my 2 cents is that it's quite the pain to change one (but I'm a sbc guy, only assuming it's the same for a 6). Regardless, a sneaky pete tool is kinda useful in helping get the old seal out / push the new one in (i.e. the difficult part on the block side above the crank journal). sneaky pete is a small metal curved punch that has the same profile as the seal - and you have to be careful to not nick your crank (so to speak) when you whack on it. That just sounds bad, sorry... Anyway, if you nick the crank, it'll tear the NEW seal and leak again. So be careful, and it's possible to git er dun without tearing the whole engine apart. Personally, I usually choose to live with a leaky rear seal until I actually pull the motor for a rebuild so I can do it right with appropriate silicone in the mating areas, etc. But sometimes pulling the motor isn't an option, I understand that. Good luck! One more thing - roller pilot bushings are usually more trouble than they are worth, a simple bronze bushing does the trick just fine. |

|

|

|

|

|

#13 |

|

Senior Member

Join Date: Oct 2009

Location: Godley, TX

Posts: 17,975

|

Re: Finally

sneaky petes:

All I remember is that I was pissed off the whole time I was using it...

|

|

|

|

|

|

#14 |

|

Registered User

Join Date: Oct 2011

Location: Houston Texas

Posts: 266

|

Re: Finally

I just inspected the fly wheel and yes i see those heat cracks you speak of.... are those bad to the point were you cant resurface the fly wheel because im on a tight budget fly wheels i have found at the local parts stores go for around $130 and up also so if i change the seal i wouldn't need to mess with the crank or bearings? i mean different people have told me different things and it sounds reasonable that the bearings would be worn and that's causing the knocking and wobbly balancer but ill have to look into it more..... past couple of days its been raining hard down here so i haven't gotten a chance to work on it but when it clears up ill check if i can move the crank around like previously suggested to check the bearings and ill have to look into the pulley... also that tool looks pretty helpful i think i have something similar in my toolbox ill have to check it out tomorrow and also ill try and upload a pic of the flywheel so yall can get an idea of the condition its in

__________________

"So she said, "Either I go or the truck goes!"....Hmm, I wonder what she's doing these days?" |

|

|

|

|

|

#15 |

|

Senior Member

Join Date: Oct 2009

Location: Godley, TX

Posts: 17,975

|

Re: Finally

I musta missed the "knock" discussion. If you have an audible knock, then need to isolate it. Could be just about anything. But, no, a leaky seal does not directly indicate a bearing problem. The knock COULD indicate that, but having both does not increase the likelihood that the knocking alone is a bearing issue. Could be coincidence - I'd be much more concerned with the knock than the leak.

As for changing the seal - if it goes "well" for you, you simply remove the pan (probably have to jack the engine up for clearance), then remove the rear main bearing cap. Half of the seal will be in the cap itslef and you can go change it at the bench. The other half is above the crank journal - if you're lucky, you can push, then push/pull it around and out and insert the other one as easily. Sorry to tell you that I've never been that lucky, but I've only tried to change a few this way - then I reverted to the "wait til I rebuild it" approach. They often break/rip/crumble and it's hard to get them out fully. Getting in is no cakewalk either. Some folks may loosen ALL the bearing caps and try to lower the crank a bazillimeter, but I'd personally never try that. If you investigate the knock, you may find it's time for a rebuild anyway. If it's a lifter, no problema, but if it's deeper down (a bud with a stethoscope might be handy), considering all the other stuff ya got going on, you may be at the point that you need a rebuild anyway. Once the motor is out, all this becomes very easy to do. I would not attempt to resurface a heat crack damaged flywheel. It's a safety thang. Realize $ tight, but it is what it is. |

|

|

|

|

|

#16 |

|

Registered User

Join Date: Oct 2011

Location: Houston Texas

Posts: 266

|

Re: Finally

the knocking i use to think it was lifters but after changing the lifters i found out it wasn't... then i was told maybe a bent push rod but checked and they are straight also i noticed as i stated above that after adding about half a quart of 40w oil it helped for the knock to not come and go so constantly ..... i have the stethoscope but honestly i cant really hear any difference i put it on the back of the engine ,front left, right and it all sounds the same to me the sound is mainly at the bottom of the engine but at times it sounds like its in the front around the water pump hopefully it wont rain this weekend and ill attempt to change the rear seal but i might be back inside asking questions on the forums for the most part ive noticed when you try to fix one thing in these old trucks another is bound to break

is that price of flywheels really at around $130? i have a friend that just got a new 350 for his 61 and the flywheel costed him about $20 so this is were im kind of confused

__________________

"So she said, "Either I go or the truck goes!"....Hmm, I wonder what she's doing these days?" |

|

|

|

|

|

#17 |

|

Senior Enthusiast

Join Date: Feb 2007

Location: Spokane Valley, WA

Posts: 8,356

|

Re: Finally

It's possible the noise could be coming from a worn out timing gear, or one with a broken tooth, especially since it seems to be in the front of the engine. I believe the stock timing set comes with either fiber or nylon teeth on the cam gear. Here's an example of what I would assume is an upgrade replacement:

http://www.oreillyauto.com/site/c/de...3453&ppt=C0141

__________________

My Build Thread: http://67-72chevytrucks.com/vboard/s...d.php?t=444502 |

|

|

|

|

|

#18 |

|

Registered User

Join Date: Oct 2011

Location: Houston Texas

Posts: 266

|

Re: Finally

but why does the noise come and go? if it were the timing gear wouldn't the noise be constant?

also ive decided ill change the rear main seal and for now the flywheel is in the shop ... i would have liked to get a new one as suggested but the budget is to tight hopefully it wont be that much of a problem to just get it turned....... ill check the pulley and rubbers i really want to get it running so i can take it to the shop and have a better variety of tools to work with

__________________

"So she said, "Either I go or the truck goes!"....Hmm, I wonder what she's doing these days?" |

|

|

|

|

|

#19 |

|

Registered User

Join Date: Oct 2011

Location: Houston Texas

Posts: 266

|

Re: Finally

Best they could do

__________________

"So she said, "Either I go or the truck goes!"....Hmm, I wonder what she's doing these days?" |

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|