|

|

|

#1 |

|

Registered User

Join Date: Apr 2008

Location: Westhope, ND

Posts: 19

|

5.3 to Trans Help

OK guys I need a little help / clarification. I am going to put a 5.3 carb in my 66 c10. Im going to be using the stock 4speed transmission. Im curious if anybody on here actually has done it. I have been doing some researching and well its confusing, since some people say to do it this way and other says do it this way. And it seems most posts are "this should work in theory". So i guess im asking for a little help from someone who has done it.

Thanks in advance |

|

|

|

|

|

#2 |

|

Senior Member

Join Date: Sep 2005

Location: Lewisville, Nc

Posts: 10,237

|

Re: 5.3 to Trans Help

The bolt pattern is the same its just finding a flywheel and clutch set up to work

Posted via Mobile Device

__________________

David fuller Ase Certified Mechanic Click here to help support our board!! 1971 Chevy c-10 under going a 4.8l LSx swap Build Thread http://67-72chevytrucks.com/vboard/s...d.php?t=421305 2007 Honda Accord my daily 145kmiles 2002 Honda Accord 4 door With 330k(sisters car) 2005 toyota Avalon 228k( brothers car) 2002 Sububran 5.3 245k 2000 Tahoe 5.3l 378 General manager for Marco's Carwash & lube |

|

|

|

|

|

#3 |

|

Registered User

Join Date: Apr 2008

Location: Westhope, ND

Posts: 19

|

Re: 5.3 to Trans Help

OK heres what I came up with. Guys have been saying to use NFW 1050 older style flywheel with a LS2 pilot bearing. Then just use the clutch and pressure plate from my trans now. Some guys say that I have to use a .040" spacer but then another guy says it not needed. To me that if I use the spacer I would run into starter issues. What do you guy think?

|

|

|

|

|

|

#4 |

|

Registered User

Join Date: Sep 2012

Location: Milwaukie OR

Posts: 135

|

Re: 5.3 to Trans Help

I used my stock 4 speed, and used the flywheel and pilot bearing that you stated, with the Centerforce dual friction clutch that I had saved from my last engine. You DO NOT need an additional spacer, the flywheel has the .400 thickness that you need. Only thing that you have to modify, is remove the little pins that come on the flywheel, then you will have to drill 3 of the pressure plate holes on your clutch just a tad bigger in order for the bolts to fit. Get a set of ARP metric flywheel bolts and your good to go.

|

|

|

|

|

|

#5 | |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 5.3 to Trans Help

Quote:

|

|

|

|

|

|

|

#6 |

|

Registered User

Join Date: Sep 2012

Location: Milwaukie OR

Posts: 135

|

Re: 5.3 to Trans Help

The other 3 pressure plate holes are the correct size for the new metric bolts, and are a staggered pattern, so the pressure plate is already held into place where it is going to be by the time you have to slightly enlarge the other three. I was concerned with the idea as well, but am very pleased with how smooth it turned out.

|

|

|

|

|

|

#7 |

|

Registered User

Join Date: Apr 2008

Location: Westhope, ND

Posts: 19

|

Re: 5.3 to Trans Help

Thanks for the help guys!

|

|

|

|

|

|

#8 | |

|

Fabricate till you "puke"

Join Date: Jun 2002

Location: Ill

Posts: 9,402

|

Re: 5.3 to Trans Help

Quote:

The other 3 need about 1/64th oversized...(.015-.016). Its really funny, 3 bolts drop right through the hat....the other 3 do not fit the hat, even off the flywheel? Also, any gen I,that I had never had pins to locate the clutch hat? Longhorn The other 3 need about 1/64th oversized...(.015-.016). Its really funny, 3 bolts drop right through the hat....the other 3 do not fit the hat, even off the flywheel? Also, any gen I,that I had never had pins to locate the clutch hat? Longhorn

__________________

69 longhorn,4" chop,3/5 drop, 1/2 ton suspension/disc brakes,1 1/2" body drop,steel tilt clip, 5.3/Edelbrock rpm intake/600 carb, Hooker streetrod shorties,2 1/2" exhaust/ H pipe/50's Flows , 6 spd Richmond trans,12 bolt/ 3.40 gears.... |

|

|

|

|

|

|

#9 |

|

Registered User

Join Date: Sep 2012

Location: Milwaukie OR

Posts: 135

|

Re: 5.3 to Trans Help

That is because only newer Gen III engines use the dowel pins to line up the pressure plate. Gen I engines used 3/8 shouldered bolts to "center" the pressure plate, so with what we are doing is using a Gen I clutch on a Gen III flywheel, because it used the same blot pattern for the clutch. So where I got confused, was they stated that NFW1050 is tapped with 3/8 threads, which mine was not. So as I read in another swap forum somewhere, I just slightly drilled the three smaller holes out, and mounted it with new metric pressure plate bolts. By the way it lined up, I couldn't see how it could be any "more centered" than what it was, by not using shouldered bolts, or dowel pins. And it runs smooth as hell. Keep in mind, this is also the "affordable" route, as I did not have the money to throw down on a $600 special swap flywheel and clutch combo, usually offered by Mcleod.

|

|

|

|

|

|

#10 | |

|

Fabricate till you "puke"

Join Date: Jun 2002

Location: Ill

Posts: 9,402

|

Re: 5.3 to Trans Help

Quote:

I am into the spot to build.....but the old setup has been "trashed" to hard ! I should start a fresh thead on this, but I feel that it will apply here? A question, for the guys that have played the LS? I know that a 97-04 Camero clutch kit will bolt to my truck flywheel....but the ? is, will it work with the gen I bell & be proper length, with the manuel linkage/throwout bearing? Longhorn I am into the spot to build.....but the old setup has been "trashed" to hard ! I should start a fresh thead on this, but I feel that it will apply here? A question, for the guys that have played the LS? I know that a 97-04 Camero clutch kit will bolt to my truck flywheel....but the ? is, will it work with the gen I bell & be proper length, with the manuel linkage/throwout bearing? Longhorn

__________________

69 longhorn,4" chop,3/5 drop, 1/2 ton suspension/disc brakes,1 1/2" body drop,steel tilt clip, 5.3/Edelbrock rpm intake/600 carb, Hooker streetrod shorties,2 1/2" exhaust/ H pipe/50's Flows , 6 spd Richmond trans,12 bolt/ 3.40 gears.... |

|

|

|

|

|

|

#11 |

|

Registered User

Join Date: Sep 2012

Location: Milwaukie OR

Posts: 135

|

Re: 5.3 to Trans Help

That I do not know. I only researched weather or not a Gen I clutch could be used on the Gen III flywheel, being that my Centerforce dual friction that I re-used only had 7000 miles on it. Try a new thread, only problem is barely anyone on here runs manual trannys. Also try PIRATE4X4.com It's just like this site, but everythings about 4x4's and there's a lot of manual trannys.

|

|

|

|

|

|

#12 | |

|

Registered User

Join Date: Mar 2014

Location: Tracy California

Posts: 98

|

Re: 5.3 to Trans Help

Quote:

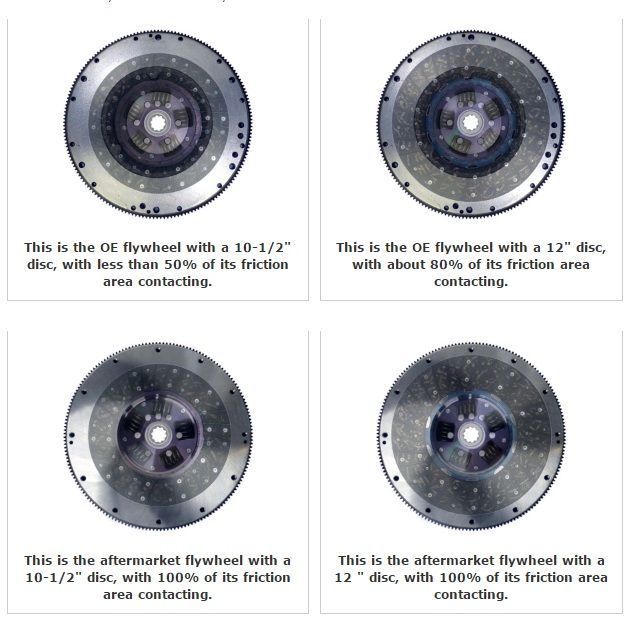

It should be mentioned that, while the LS1 flywheel will "function" with an old-school 10.5 or 12" clutch, it is the WRONG solution because of the large amount of material that is missing from the center contact area of the LS1 style flywheel; A typical 10.5" or 12" clutch as we have with an old-school SBC clutch will only have about half of its friction surface actually engaged with the flywheel, because of this. Like many others, I read may posts here and elsewhere about simply using the LS1 flywheel (Sachs NFW1050) and was all fired up about being able to spend only 65 bucks on that flywheel, and be in business. Not the case. The McLeod flywheel (460535) is the right flywheel to use, unfortunately it is $400 but there is presently no cheap alternative. Novak also sells a flywheel (which I am 99 percent sure IS the McLeod 460535). LS1 Flywheel (Sachs NFW1050):  The McLeod 460535:  Excellent depiction of the problem that exists when trying to use the LS1 style flywheel (taken from Novak's site):

|

|

|

|

|

|

|

#13 |

|

Registered User

Join Date: Sep 2012

Location: Milwaukie OR

Posts: 135

|

Re: 5.3 to Trans Help

Fact is, that no one can afford the Mcloed flywheel, and after three solid years of use my current set up has proven just fine with the SACHSnfw1050 flywheel. Most of us don't have the time to just sit around and wait for the next perfect solution.

Posted via Mobile Device |

|

|

|

|

|

#14 |

|

Registered User

Join Date: Mar 2014

Location: Tracy California

Posts: 98

|

Re: 5.3 to Trans Help

It may work fine if you never push your truck hard; and if you just cruise around town....just don't kid yourself that it's the right way to do it.

Using that setup, you literally have about half of a normal clutch engagement. I regularly wheel my 72 blazer on the rocks; its not an option for me to run that way. Making it out and making it home are the priorities, hence I had no problem paying the $$$ for the McLeod flywheel. Posted via Mobile Device |

|

|

|

|

|

#15 |

|

meowMEOWmeowMEOW

Join Date: Sep 2009

Location: MKE WI

Posts: 7,128

|

Re: 5.3 to Trans Help

What? I'd actually say automotive hobbyists are the MOST likely to dig up $400 for a flywheel.

__________________

'66 Short Step / SD Tuned / Big Cam LQ4 / Backhalfed /Built 4l80e / #REBUILDEVERYTHING  |

|

|

|

|

|

#16 |

|

Registered User

Join Date: Sep 2012

Location: Milwaukie OR

Posts: 135

|

Re: 5.3 to Trans Help

That's a good point, maybe I'm the only broke one trying to fix up my truck.

Posted via Mobile Device |

|

|

|

|

| Bookmarks |

|

|