|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Watch out for your cornhole !

Join Date: Jun 2003

Location: Azle, Texas

Posts: 14,162

|

The Hillbilly Deluxe dually build

If you're a country music fan, the name Hillbilly Deluxe will make sense.

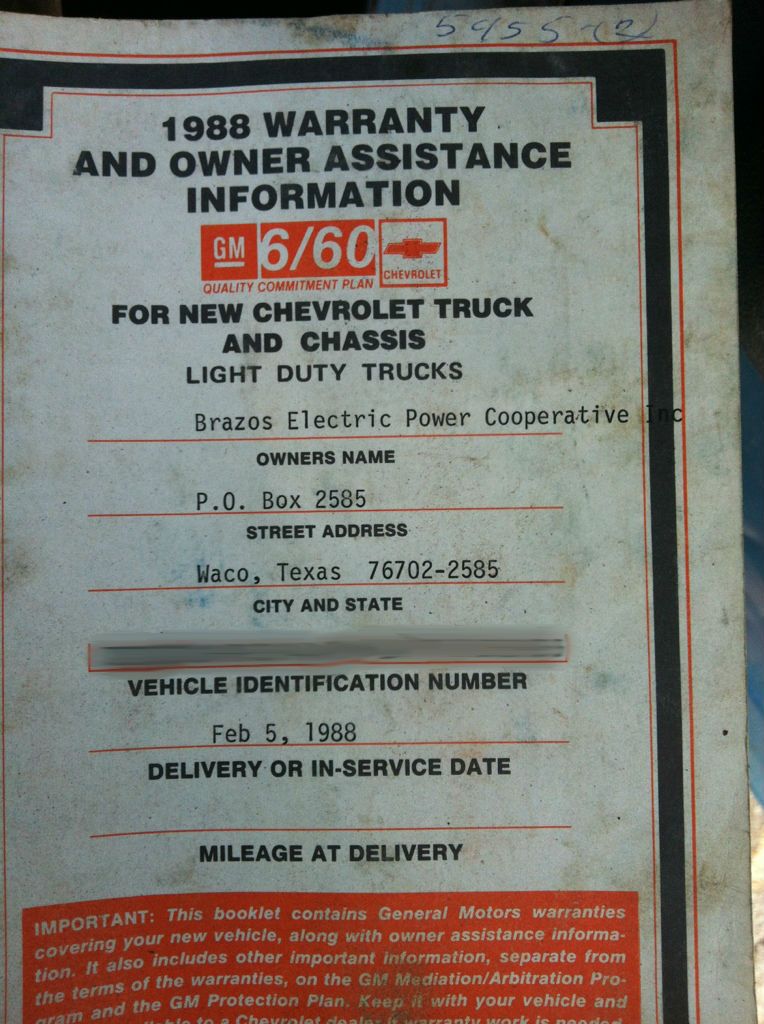

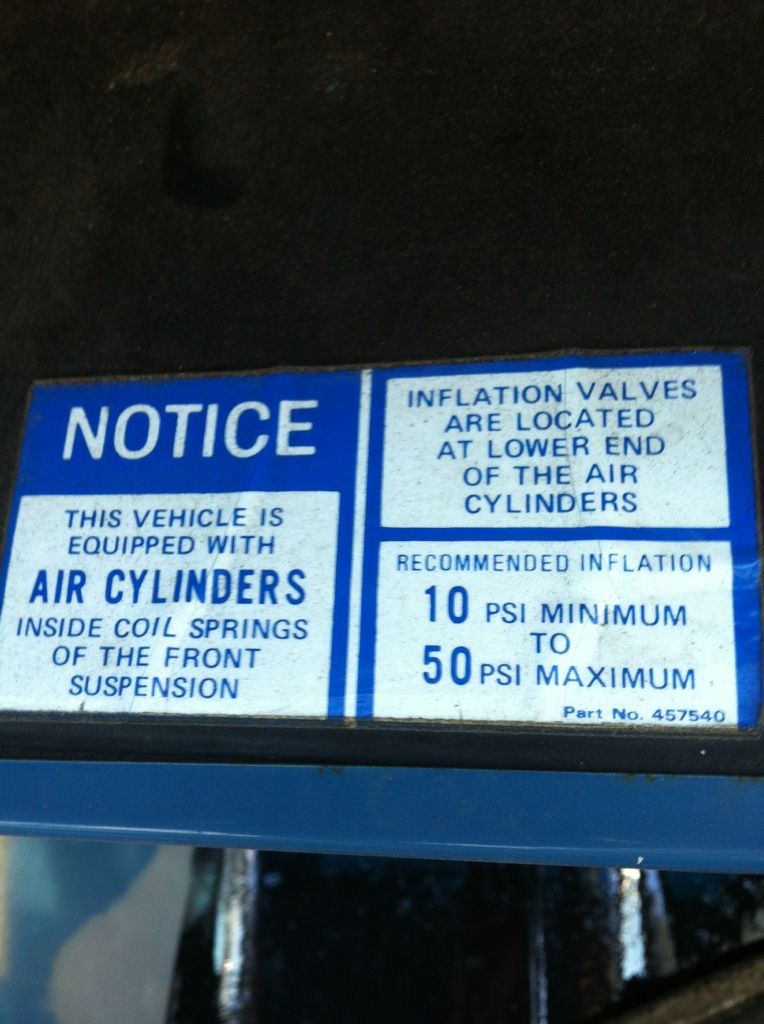

I'm a very small town guy so in my world there are a lot of guys who build duallys and other heavy duty trucks. I needed a heavy truck to pull my trailers and haul hay for my animals with so I spent a long time looking for just the right truck. I wanted simple, cheap and strong. I finally found this truck local for cheap. Real cheap. My criteria were -Heavy duty cab and chassis with a nice flat bed -Big block -Fuel injected -Proper color (I'm a white truck guy) -Standard transmission And it was real cheap. It's an 88 model R30 with a 454 TBI engine, Muncie SM465 transmission and 4.56 geared locker rear end. As soon as my buddy saw all of that he said "You don't often need to pull a church off it's foundation, but when you do, you won't even have to break off idle". It's pulls like all of my old diesel pickups used to, up to about 60 miles per hour, when it gets gear bound. But, let me say it again, it was cheap. I bought it for what the engine core alone would be worth.   It's a local Texas truck with very few miles on it so it's mostly solid already...  I've never owned a heavier spec'd truck than this one. Heavy springs, big brakes, 4.56 gears, heavy cooling system, all of that. It surprised me that it even has air bags in the front coil springs. Glove box sticker for the air bag option....  That will be the last time I use the words "air bags" in this thread. If that's your thing, along with semi wheels and all of that, you're in the wrong thread, just hit the back button right now. As far as I'll be going with this is to lower it statically and add some 16 inch Alcoas. That's as trick as it will be. What this thread will be is very heavy of basic nuts and bolts tech stuff. I refuse to own a vehicle that leaks, drips or seeps any fluid at all, so that's first step on this build. There has been a whole lot of pressure washing and leak fixing going on first thing. I'm a normal guy with a very normal income who has two daughters in private school, so the budget is the main factor that controls progress. But, that said, I have been attempting to use as many Made in USA parts as possible (and have been doing very well in that area), and will only use the best part available on the market. There is very little local parts store generic stuff on this build. I have been ordering most everything so I can get premium stuff like Gates, Felpro, Moog etc for the best prices. Much, much more to come. Last edited by Tx Firefighter; 12-02-2012 at 11:46 AM. |

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|