|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Registered User

Join Date: Jul 2014

Location: Chattanooga Tn

Posts: 231

|

Hood Nose Replacement Write Up

If I missed it I apologize but while searching today I couldn't seem to find much on replacing the nose of the hood that's notorious for rusting out on our trucks. I was able to pick up two more hoods last week so I figured with 3 hoods surely I can make one good one. I wanted to test the waters since I had little knowledge on making the swap so I decided to let loose on the worst of my 3 hoods tonight. This is a small recap of the process, although not much detail, its pretty straight forward.

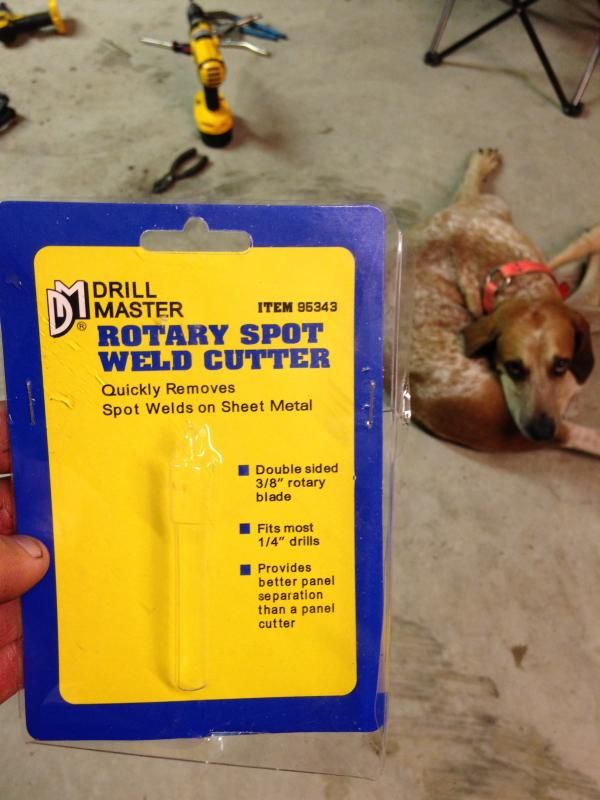

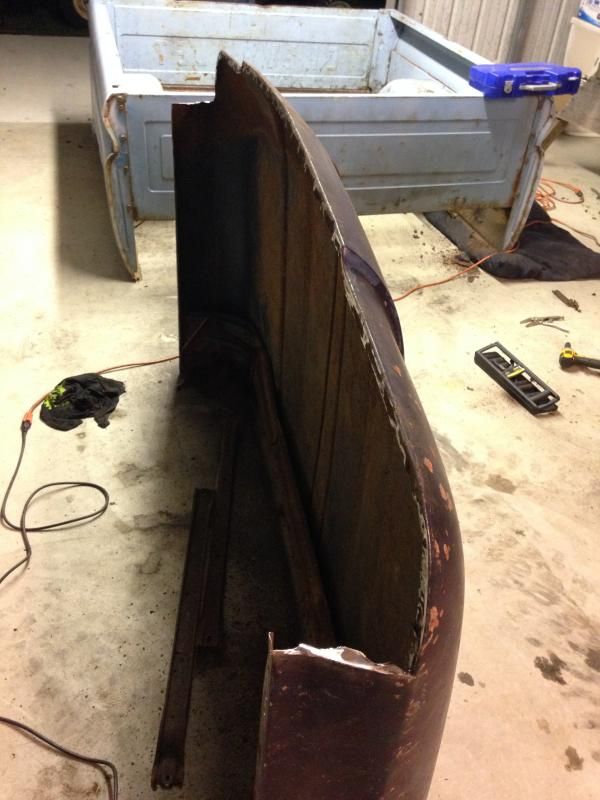

Any suggestions you guys can share would be great. I'm not sure that I did it the preferred way. Once the nose support is removed, how are you guys getting the actual nose off? I used a cutting wheel, seemed to be the only way to get in there since mine was rusted to the point I couldn't see the spot welds. I researched spot weld bits and actually landed on the one from Harbor Freight. Its $4.99 and is double sided so when one side wears out just flip it over. It had great reviews on their website so I figured Id give it a try. There are roughly 40 spot welds and I still haven't flipped it over to use the other side, def recommend it!  Remove the two supports that are under the hood.  As I said there are roughly 40 spot welds on the underside edge of the hood. First I hit it with a wire wheel so I could see the welds better. I then used a 1/8 bit to drill some pilot holes. After that I was ready for the spot weld bit...   Once all the spot welds are loose, pull the nose support out working it from one side of the other.  Nose support removed.  The next part I wasn't sure of the correct way to go about it, but seeing that my spot welds are completely gone to the naked eye from rust, and I saw no way of even getting the drill and bit in there, I used a cutting wheel and carefully cut down the seam where the hood meets the nose clip.  Nose removed, still plenty of lip on the hood to weld a new nose clip onto the hood.  Nose and support removed.  Take your time when removing the support and when cutting. If able, leave more than what you need when cutting the nose off, you can always come back later and clean it up, reassuring that you have plenty to spot weld the new nose to. Working slow, the job took me about 2 hours. Hope this helps someone! |

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|