|

|

|

#14 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 4L80E & TH400 Tech.

Rollerizing the Output......

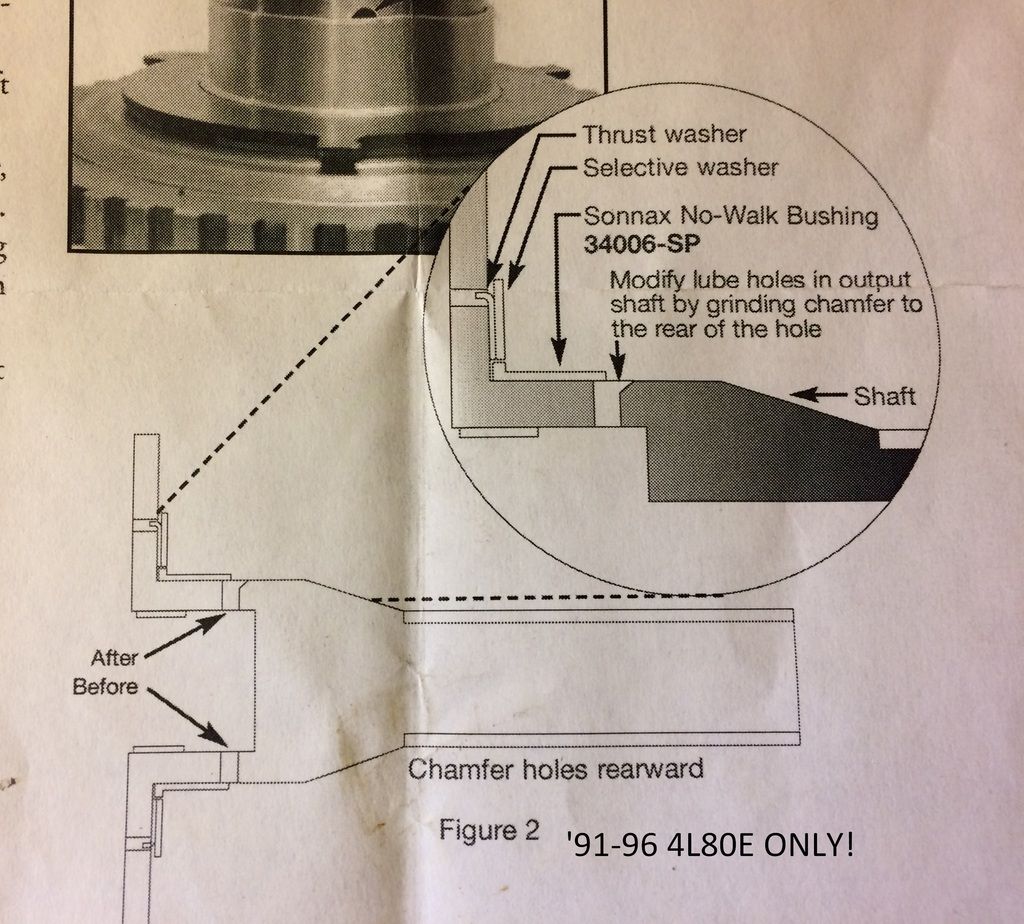

Parts needed.... TH350/TH125 Pump Bearing, GM part# 9436851 TH350 Unit End-play Shims (assortment) If building a TH400....4L80E Pump Bushing (.700" wide) If building a 4L80E....Sonnax 34006-SP Bushing (Special instructions!) Before tearing the unit down, Check rear unit end-play & record the reading, This will give a very good baseline when setting final end-play upon assembly. If you do find a bad Torrington, Sun-Gear, Carrier, Etc in the lower half....This measurement was for naught, But if your reusing everything....It can save alot of time. Case Bushing installation & Tech.... TH400 Directions When using a .700" wide '97 & up 4L80E Pump Bushing, You need to leave the bushing sticking up out of the Case about .080". Red Loctite the O.D. of the Bushing before installation. This Bushing has no oil grooves in it, But the Torrington doesn't require the amount of oil that the Thrust Washer did. I haven't had ANY problems with using a non-grooved bushing as lube oil is fed directly to the face of the bushing through a lube hole in the output shaft. **If you have a TH400 & want a bushing with oil grooves, Use a TH400 Case Bushing, It is only .620" wide so you will lose some support by offsetting the bushing .080" into the Case. I recommend Loctite & Stacking the Bushing in place in this scenario ** 4L80E Directions '91-'96 "Conventional Lube"...... Using a Sonnax 34006-SP, Sit the bushing in the back of the case & mark the location of the 2 lube holes on the lip of the bushing. Take a file & file 2 "V's" though the lip of the bushing. This will eliminate the bushing lip from restricting lube flow to the Geartrain, Case Bushing & Extension Housing Bushing. Coat the O.D. with Red Loctite. Drive the bushing in from the BACK of the case, This is opposite from the directions that come with the bushing. Seat the bushing all the way & it will be sticking up out of the case far enough to register the bearing without you having to measure. Note the 2 Lube Holes in the Output Shaft....... Temporarily install .030 worth of shims over the Bushing inside the case. Temporarily install the Bearing over the Bushing (Silver side up). Use TransJel if needed to hold the shims & bearing in place. Temporarily install the Output Shaft. IF the 2 lube holes in the Ouput are blocked or partially blocked by the bushing.....You will NEED to chamfer the holes toward the REAR. See picture. '91-'96 4L80E's lube the geartrian backwards from a TH400, It is imperative that the lube holes on the shaft are open to the area between the bushing & Seal!! '97 & up Center Lube 4L80E.......Using a Sonnax 34006-SP, Sit the bushing in the back of the case & mark the location of the 2 lube holes on the lip of the bushing. Take a file & file 2 "V's" though the lip of the bushing. This will eliminate the bushing lip from restricting lube flow to the Case Bushing & Extension Housing Bushing. Coat the O.D. with Red Loctite. Drive the bushing in from the BACK of the case, This is opposite from the directions that come with the bushing. Seat the bushing all the way & it will be sticking up out of the case far enough to register the bearing without you having to measure. These units do not lube the geartrain from the back of the case, They Lube from the Center Support....The reason there are no lube holes in the Output. Case Lube Hole Locations  Bushing Modification Drawing  Sonnax 34006-SP, Install with lip toward the rear of the case!  '91-'96 Output Lube Hole Modifications

Last edited by clinebarger; 06-15-2017 at 09:43 PM. |

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|