|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

|

|

#1 |

|

Registered User

Join Date: May 2011

Location: Anderson SC

Posts: 3,901

|

Mini Tech Tip: Body Shims

To read the original thread and discussion on this topic go here- LINK

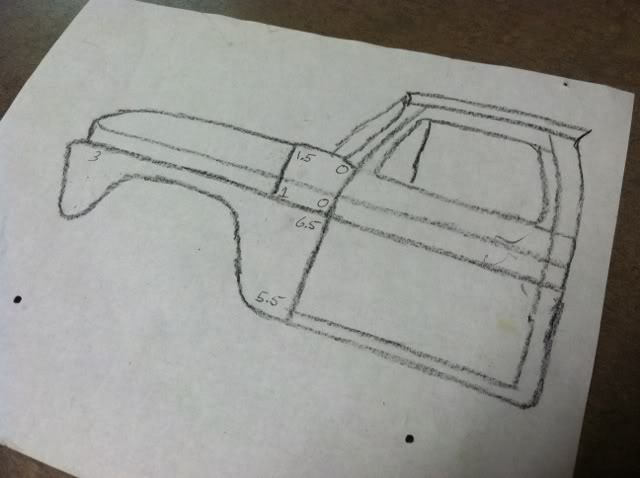

When you're mocking up body panels during metal/bodywork you need a way to keep up with how many shims you need in each location, especially between the final tear down for paint and reassembly- trust me, you won't be able to remember where all those shims go! Make a drawing of your truck and write down how many shims go in each spot on the drawing. If you've got shims with different thicknesses make sure to make note of that as well. Shims are available in many different heights and the thinner ones can really help to get the panels adjusted dead on. On the '65 I restored I found shims that were around .010" thick to really fine tune the panel flushness. Posted via Mobile Device

__________________

Project Goldilocks '66 C10 Short Fleet BBW Build '65 C10 Highly Detailed Stock Restoration Thread '78 Camaro Targa Roof Build '55 International Metal/Body/Paint Work '66 F100 Full Rotisserie Restoration '40 Packard 120 Convertible Coupe Restoration How To Restore and Detail an Original Gauge Cluster How To Detail Sand Body Panels, Edges, Corners, Etc Last edited by augie; 05-09-2012 at 01:00 AM. |

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|