|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Registered User

Join Date: Sep 2016

Location: Redington Beach

Posts: 1,317

|

Depinned engine harness --- now ... ??

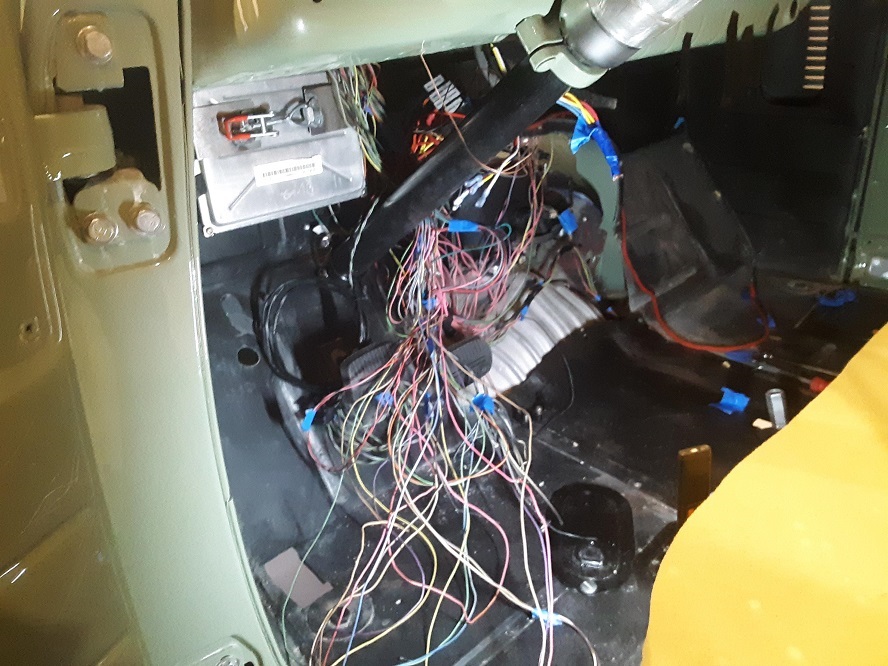

So unloomed and depinned this bad boy about 6+ months back.

Now looking to finish it off and get it into they truck. Whats the best approach here ? Stuff like .... Routing and lengthening/shortening wires ..... which ones typically ..... injectors seem to be a standout as they are in completely different positions. eg first part of harness from the PCM .... .annd then about smack bang in middle of the middle run. Grounds - how many should there be ? Where do they connect (Harness was removed by a friend whilst I was dissaembling the trans). Other suggestions ? This a 2007 lq4 6.0.

__________________

FAKKY 57 PANEL BUILD Last edited by FAKKY; 03-10-2019 at 01:12 PM. |

|

|

|

|

|

#2 |

|

Registered User

Join Date: Sep 2016

Location: Redington Beach

Posts: 1,317

|

Re: Depinned engine harness --- now ... ??

ok

so looking at PSI stock harness pic it looks like they extend the injector bank.  Someone explain the AC control. My understanding is you can run in 2 main modes either as a manual seperate circuit and manual relay control or via PCM. So thinking want to do via PCM ...... so then its just programming in the PCM as well as a trinary switch ? Single fan in my case. Any more specifics ?

__________________

FAKKY 57 PANEL BUILD |

|

|

|

|

|

#3 |

|

Registered User

Join Date: Sep 2016

Location: Redington Beach

Posts: 1,317

|

Re: Depinned engine harness --- now ... ??

This video is ok .... but its more of a traditional hotrod.

https://www.youtube.com/watch?v=KUDsYKOYwUg Not quite sure with regard to running it via PCM control ...... especially if using a single fan with single speed setup.

__________________

FAKKY 57 PANEL BUILD |

|

|

|

|

|

#4 |

|

Registered User

Join Date: Sep 2016

Location: Redington Beach

Posts: 1,317

|

Re: Depinned engine harness --- now ... ??

*BUMP*

Im *guessing/thinking* - for wiring/pcm etc I need to ..... 1) Enable FAN#1 if not enabled. Disable FAN#2 so only 1 fan. 2) Blue connector #41 -> add a pin to go to fan relay to ground circuit. -- This will give you electric fan control based on engine temp. -- But now for AC 3) Add trinary switch to compressor circuit to switch on/off fan based on hi/low pressure signal. a) Not quite sure if thats right b) The wiring exactly

__________________

FAKKY 57 PANEL BUILD |

|

|

|

|

|

#5 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 778

|

Re: Depinned engine harness --- now ... ??

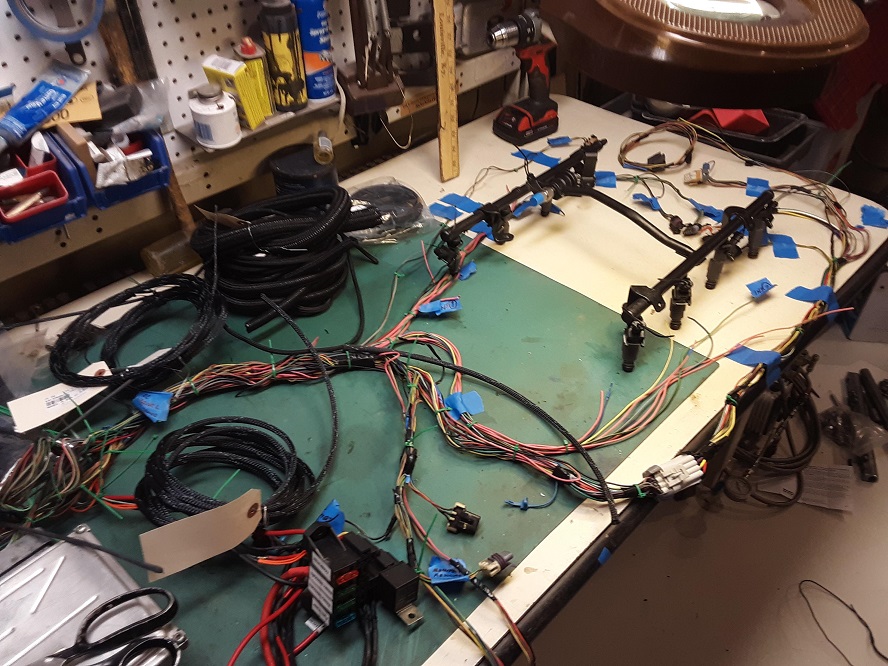

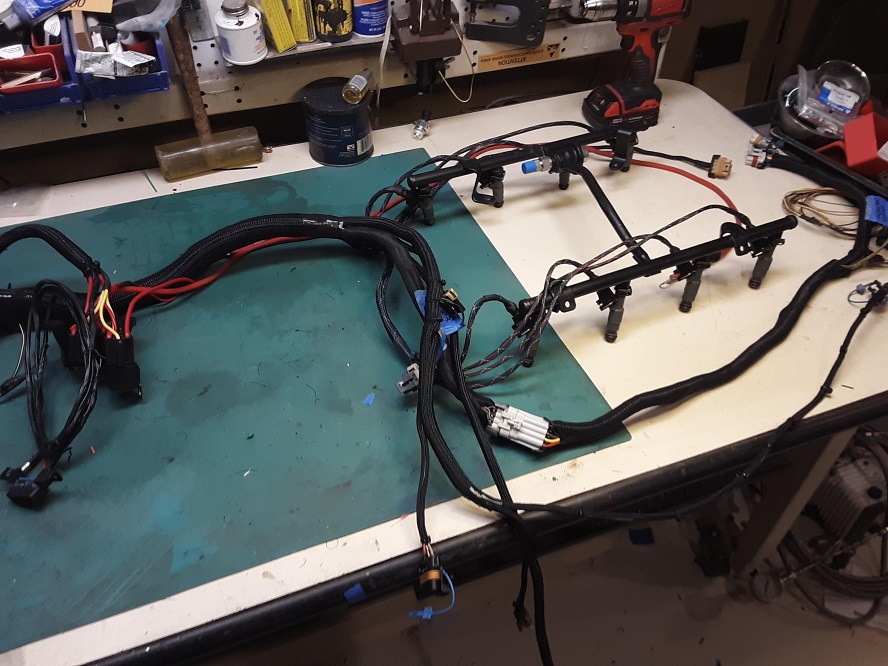

I recently reworked my factory harness to stand-alone for my '49. My PCM is in the cab and the ignition coils are remote mounted. I didn't have to extend anything, but the remote coils required a plug-and-play harness extension to reach.

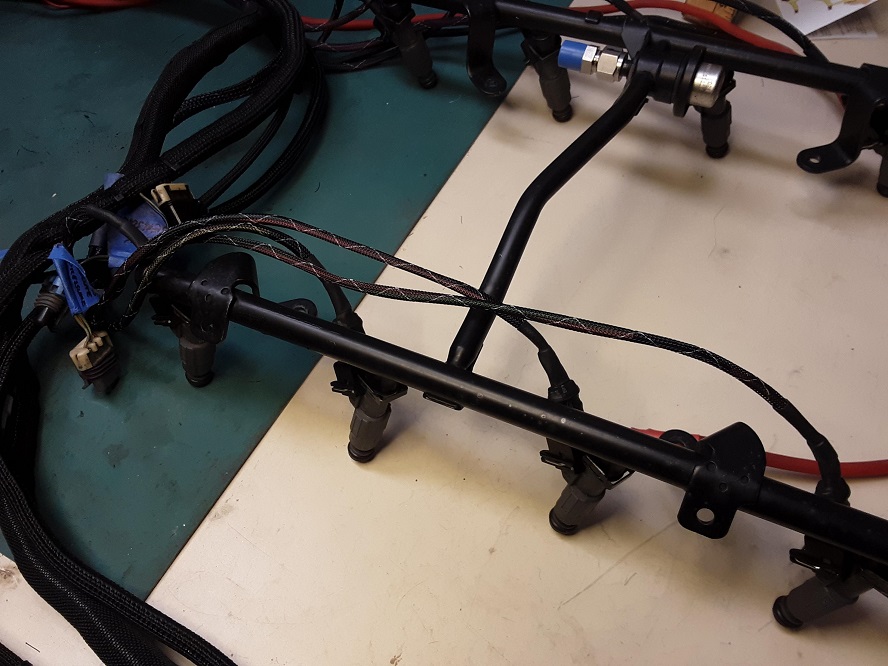

I laid mine out pretty much like you have in the picture. I made a discrete wire bundle for each of the sensors coming off of the connectors to the PCM. From the factory, the wire paths seem to lay out pretty logically - except for the grounds. They appear to be added after the harness was laid out in the factory so they jump across the discrete wire paths. To get discrete wires going to each sensor, I cut the grounds out of them where necessary and marked them so I could connect them later When I had the harness with separate wire paths to each of the connectors, I draped the harness over the engine and mounted the PCM in the cab where I wanted it and connected everything and routed the wires where I wanted them. Where wires were too long, I coiled the excess up and taped it. Where there were branches and tees in the harness, I marked them too with tape. Once I knew the correct lengths and where the branches were, I pulled the harness off and put it on the bench to shorten the wires where necessary and loom it. To shorten the wires, I prefer soldering the splice and covering it with shrink wrap, but others prefer crimp connectors. Your preference. Once I had everything to the right length, I depinned most of the red and blue connectors for the PCM to get the tangles out of the wire and shorten a few more that needed it. De-pinning and re-pinning the PCM connector is pretty mindless work and my concentration tended to drift, so once I was done I rechecked everything against the pin-out .pdf that's posted over on LT1Swap.com. Pay special attention to the grounds and make sure they're all in place. To loom the harness, I used harness loom from Aircraftspruce.com. When I had the harness on the bench, I measured the diameter of the wire bundles and their length and tallied up what I'd need on a spreadsheet. Aircraftspruce.com sells it by the foot and all the looming materials were about $25 for mine. AircraftSpruce.com has two types of loom - split and closed (the chinese finger stuff). Since I had to change the injector connectors anyway, I put the closed loom on the injector leads, but the quality of their split loom is so nice, I wouldn't bother otherwise. I think black electrical tape looks cheesy on a harness, and AircraftSpruce.com sells a silicone tape that's far superior, and I used that to close the loom at every branch. I have my PCM set up to control my radiator fan. For a truck harness and PCM I think you have to add a wire to the harness, IIRC. I'll hook up my trinary switch so it will also ground the fan relay if the AC is on and the engine is cold - don't want high head pressures in the hot summer when you jump in the truck, need AC but the engine is cold A few photos- Here's the harness draped onto the motor. Some of the discrete legs had mis-matched wire lengths that I pulled into the cab to tape in coils and shorten on the bench.  Here's the firewall side with the injector leads on the top of the engine . To shorten these wires, I just cut them to length since I was replacing the connectors anyway.  Here's the taped up harness on the bench ready to loom. I found it easier to get the wire lengths correct if I used the fuel rail as a guide.  Here it is loomed up. That big connector in the leg that goes to the coils is the extender harness (hidden down in frame rail)  Here's a detail of the injector leads with the 'chinese finger' loom. There's several layers of shrink tube at the injector connector to provide strain relief. If I can figure out a nice cover for these, I should be able to pretty much hide all the wiring in my engine bay, but that's a future project.

|

|

|

|

|

|

#6 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 778

|

Re: Depinned engine harness --- now ... ??

Post Script - I have a Vintage Air going in my truck. I'm going to let the VA system control my compressor. I know I can get support from VA if it is stand-alone but if it is integrated into the PCM, I'm kinda screwed since I don't have any PCM edit capability.

|

|

|

|

|

|

#7 |

|

Registered User

Join Date: Sep 2016

Location: Redington Beach

Posts: 1,317

|

Re: Depinned engine harness --- now ... ??

Thanks thats very useful. Wish I had known about that webiste for loom etc.

The main deal on the harness is the position of the injectors. Id have to pull the harness out again but I think I circled them here. Just that one is so short in the middle of the harness and the other is way further up.  On the AC wiring - Id rather let the PCM control the FAN on based on dash control or engine temps. BUt also allow the AC clutch to be disabled on high/low. I think thats typically done via a trinary switch ....... so when head pressure gets too high or engine temp gets too high - the fan will automatically come on. Guess the other option is just to run the fan all the time. Bypass tempsensor and PCM.

__________________

FAKKY 57 PANEL BUILD |

|

|

|

|

|

#8 |

|

Registered User

Join Date: Dec 2009

Location: Independence Mo

Posts: 4,119

|

Re: Depinned engine harness --- now ... ??

I wouldn't have the fan run the whole time the A/C is on, that will just prematurely wear your fan out. The way e015475 said he wired his is the way I do it too. Run the VA as stand alone, and the trinary switch will control the compressor and also provide a ground to the fan relay to turn the fan on based on head pressure, that way it shuts off on the highway. You will want to let your tuner know though so he can disable the error reporting for the fan code because it may set a code when the PCM sees the relay grounded but didnt command it.

__________________

My '72 short bed build. http://www.ls1tech.com/forums/conver...6-0-4l80e.html 5.3 swap into my RUSTY '71 C10 http://ls1tech.com/forums/conversion...71-c-10-a.html |

|

|

|

|

|

#9 | |

|

Registered User

Join Date: Sep 2016

Location: Redington Beach

Posts: 1,317

|

Re: Depinned engine harness --- now ... ??

Quote:

What does the wiring on that look like schematically. Dont use PCM at all ? Just temp sensor.  So you setup the FAN on the FAN relay without PCM control (pin 42 on C1). But doesnt the PCM get a reading from the THERM/TEMP switch to tell the fan to turn on. Meaning - if you dont wire in the fan via PCM .... then do a direct wire connection from the thermostat sensor? Basically treat it like a non PCM controlled hotrod. I can disable all the PCM stuff with the HPTuners I bought I believe. Then wire up all the AC stuff however you want ..... but have a ground wire "splice" into the ground circuit of the fan relay ? That way generally the temp sensor is controlling the FAN on/off ..... but the AC can also turn fan off if pressures get too high/low.

__________________

FAKKY 57 PANEL BUILD |

|

|

|

|

|

|

#10 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 778

|

Re: Depinned engine harness --- now ... ??

You're making this way too complicated.

To turn on the fan to cool the engine, the PCM grounds a external relay based on a temp selected in the PCM tune. The trinary switch can also ground the same relay when the head pressure gets too high and the fan needs to come on to cool the ac condenser and bring the pressure down. The fan shouldn't run all the time. It should be modulating the temp in the radiator as required, or be on when the head pressure is high in the ac. The fans shouldn't be running at highway speeds at all, and if they are, it can be an impediment to cooling. You can disable the PCM stuff in HPTuners and shove a temp bulb into the radiator (or a thermo switch as shown in your drawing) for a stand alone control and wire your trinary switch to ground pin 85, but why when you have HPTuners? It's like killing ants with a hammer - it works but it isn't a very elegant solution and it is just another system to fail. |

|

|

|

|

|

#11 | |

|

Registered User

Join Date: Sep 2016

Location: Redington Beach

Posts: 1,317

|

Re: Depinned engine harness --- now ... ??

Quote:

So basically ....... if I have it [now]. 1) Delete FAN 2 in PCM as I dont have it. 2) Use wire 42 on C1 to ground the relay to activate FAN based on engine temps input from PCM. 3) From the AC system - use a trinary switch. The 3rd wire will also ground to active FAN if AC pressure gets to high. that it ?

__________________

FAKKY 57 PANEL BUILD |

|

|

|

|

|

|

#12 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 778

|

Re: Depinned engine harness --- now ... ??

I think you've got it.

Some of the problem may be the two fan controls in the PCM, which is a little confusing- this isn't two separate fans, this is to step the fan speeds Please forgive me if you already know this....... All of the car applications of the LS engine and some of the trucks have two speed fans. Using a couple of relays, the fans first come one at a lower temperature commanded by the PCM. The two fans are wired in series by the relay so they each see 6V when the first pin is grounded and because they're dc motors they'll run at half speed, At a higher water temperature, the second pin grounds and the relays place the fans in parallel so they both see 12V so they will run at full speed. It is easy to make the 6v/12v fan speed control out of a couple of relays. If you have room on your radiator for two fans and HPTuner to set them up, it makes for a much less noisy cooling fan. |

|

|

|

|

|

#13 |

|

Registered User

Join Date: Sep 2016

Location: Redington Beach

Posts: 1,317

|

Re: Depinned engine harness --- now ... ??

Thats awesome. Had no idea. Had heard about series versus parallel hookup but never read into it. Even googling didn't give me too much info except for some computer forums ...... - but founds this after googling what you said above

https://www.youtube.com/watch?v=X3IinhYkAP8 Thanks again !!! Helps immensely.

__________________

FAKKY 57 PANEL BUILD |

|

|

|

|

|

#14 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 778

|

Re: Depinned engine harness --- now ... ??

Here's a thread from LS1tech.com that has a couple schematics in it for a two speed fan controller. Post 15 looks like an extract out of the factory manual-

https://ls1tech.com/forums/conversio...e-i-m-5-a.html If you're running just one fan on your radiator/condenser, you might want to look into a PWM (pulse width modulated) controller to continuously vary fan speed as a function of water temp. Quite a few modern cars come with this technology to minimize cooling fan noise. Having said all this, I have a daily driver that's been switching the fan on and off high speed for the last 100K miles - no problems. It is a little noisey, but so what. I just need to use the 50A relays or it will eventually melt them. |

|

|

|

|

|

#15 |

|

Registered User

Join Date: Sep 2016

Location: Redington Beach

Posts: 1,317

|

Re: Depinned engine harness --- now ... ??

Thanks e015475

Some good reading. Do you recommend a PWM ... else something like https://www.jegs.com/i/Derale/259/16795/10002/-1 I got the harness layed out last night ..... pulled it off and started taping it all. Will get it spliced into the BD AUTO DIY relay kit ....... and should be good. https://www.bp-automotive.com/produc...i-24x-engines/

__________________

FAKKY 57 PANEL BUILD |

|

|

|

|

|

#16 |

|

Registered User

Join Date: Nov 2013

Location: Show Low, Arizona

Posts: 778

|

Re: Depinned engine harness --- now ... ??

If you are running two fans, you can use the 3-relay setup to run the fans at half speed most of the time and full speed when there's big demand on the cooling system.

If you only have one fan and it is noisier than you'd like, consider a PWM variable speed control. If the fan noise really doesn't bother you, just hook the fan (or fans) to a 50A relay and ground it with the PCM to run the fan at 100% (this is what I'm doing - I have a 16" SPAL fan in a shroud. The noise would have to bother me quite a bit to part with $165!) |

|

|

|

|

|

#17 |

|

Registered User

Join Date: Sep 2016

Location: Redington Beach

Posts: 1,317

|

Re: Depinned engine harness --- now ... ??

Think I'll just go with teh single fan like you suggest - if its too noisy ..... deal with it then.

On the harness ...... the purple wire that goes to the smaller post on the starter. Seems like in a 4 wire hookup people it just goes directly to the ignition switch (key switch). So literally it just go the switch in the drivers key/ign on ? Seems large and I thought the NSS was somehow involved here (to prevent starting etc ). Ok read some more (general not LS specific) ..... so this should go through a relay. 30 to battery 12v 85 to chassis ground 87 - your purple wire from starter (in harness) 86 - your keyed ignition. BUt is this tied in somewhere for NSS or do you have to add that somewhere ....

__________________

FAKKY 57 PANEL BUILD Last edited by FAKKY; 03-24-2019 at 04:06 PM. |

|

|

|

|

|

#18 |

|

Registered User

Join Date: Dec 2009

Location: Independence Mo

Posts: 4,119

|

Re: Depinned engine harness --- now ... ??

Do you have a NSS on your steering column or shifter somewhere? If so you can just use that, or you can use the one bolted to the transmission, but you'll need a relay to use it. The benefit to the trans mounted one is it's more precise and always works in park and neutral where as a column mounted one can be somewhat vague due to the slop in the linkage.

__________________

My '72 short bed build. http://www.ls1tech.com/forums/conver...6-0-4l80e.html 5.3 swap into my RUSTY '71 C10 http://ls1tech.com/forums/conversion...71-c-10-a.html |

|

|

|

|

|

#19 | |

|

Registered User

Join Date: Sep 2016

Location: Redington Beach

Posts: 1,317

|

Re: Depinned engine harness --- now ... ??

Quote:

Just trying to work out which wire provides ground out of that. Also ..... with the relay ...... 30 - 12v power from battery with (inline fuse/fuseable link ) ? 86 - wire from key ignition. 87 - goes to purple starter wire in harness to give 12v on crank. 85 - ground from NSS .. not sure which wire Best way to protect that circuit (fuseable link) and what amperage relay etc ? Think the purple wire is a 12awg which I think is max 41A. https://www.amazon.com/Pico-8124PT-G...3463780&sr=1-9 https://www.amazon.com/ARTGEAR-Harne...omotive&sr=1-5

__________________

FAKKY 57 PANEL BUILD |

|

|

|

|

|

|

#20 |

|

Registered User

Join Date: Dec 2009

Location: Independence Mo

Posts: 4,119

|

Re: Depinned engine harness --- now ... ??

I use fuses. The battery power to the relay on terminal 30 gets a 40a fuse, the purple wire coming from the ignition switch gets a 10a fuse, then that wire goes to pin 12, a pink wire on the NSS plug. Pin 1, a green wire coming out of the NSS plug then goes to terminal 86 on the relay. Terminal 85 will go to ground, and 87 will go to the starter solenoid. I also generally use 40a relays.

__________________

My '72 short bed build. http://www.ls1tech.com/forums/conver...6-0-4l80e.html 5.3 swap into my RUSTY '71 C10 http://ls1tech.com/forums/conversion...71-c-10-a.html |

|

|

|

|

|

#21 | |

|

Registered User

Join Date: Sep 2016

Location: Redington Beach

Posts: 1,317

|

Re: Depinned engine harness --- now ... ??

Quote:

Ok a little more confused on that setup - do you have a pic on the web thats similar ? Sorry obviously a little noob on most things ..... but wiring especially at times. I think Ive seen some multi relay - fuse block setups on youtube but thnk generally they have 1 fuse on the power side only for each relay. https://www.youtube.com/watch?v=BvFHA1xY10w Anyway - back to the pinouts ....... Is there somewhere that explains that --- Im guessing you know how to read a full wiring schematic properly ...... so you knew hoe to do that ? Just I havent read it anwhere ..... and my chances of getting a schematic right are about as good as kansas winning the NCAA right now. And If I get it wrong - assuming truck wont start  -- I found an old thread of yours ..... http://67-72chevytrucks.com/vboard/s...d.php?t=615830 but havent seen many people talking about this in other threads - do most people not wire the NSS ?

__________________

FAKKY 57 PANEL BUILD Last edited by FAKKY; 03-24-2019 at 08:58 PM. |

|

|

|

|

|

|

#22 |

|

Registered User

Join Date: Dec 2009

Location: Independence Mo

Posts: 4,119

|

Re: Depinned engine harness --- now ... ??

What part do you not understand? That drawing g I made in the thread you linked shows it pretty good.

__________________

My '72 short bed build. http://www.ls1tech.com/forums/conver...6-0-4l80e.html 5.3 swap into my RUSTY '71 C10 http://ls1tech.com/forums/conversion...71-c-10-a.html |

|

|

|

|

|

#23 | |

|

Registered User

Join Date: Sep 2016

Location: Redington Beach

Posts: 1,317

|

Re: Depinned engine harness --- now ... ??

Quote:

Here are the parts not understanding. 1) I didnt find a single thread explaining that wiring until I searched on some keywords you provided on pinout of the OEM NSS. So Im guessing most people dont do it this way - they just use a column/floor shift with a 2 wire setup that prevents the starter from cranking ? 2) How did you work out that was the way to wire it ? Eg Having the ignition switch going to Pin12 of the range sensor and that that would work ? Just experience and reading schematics and understanding circuitry better ? eg I was searching on Pin #34 as that was what was registered at LT1swap. "Transmission Range Switch Signal P (A/T) PCM can be programmed to accept a SINGLE WIRE park/neutral signal on this PIN, if no trans mounted range sensor is present" <== but guessing this is if your using an aftermarket shifter with NSS ? So - just not sure how you worked that out - except for being just clever  Read for 4 hours on this. Found nothing. Read for 4 hours on this. Found nothing.3) Not clear on how you fuse every wire on each pin of the relay. Physically how is that done. Thx nova/e015475all ....... / none of this would get done without learning from you lot.

__________________

FAKKY 57 PANEL BUILD |

|

|

|

|

|

|

#24 | |

|

Registered User

Join Date: Dec 2009

Location: Independence Mo

Posts: 4,119

|

Re: Depinned engine harness --- now ... ??

Quote:

__________________

My '72 short bed build. http://www.ls1tech.com/forums/conver...6-0-4l80e.html 5.3 swap into my RUSTY '71 C10 http://ls1tech.com/forums/conversion...71-c-10-a.html |

|

|

|

|

|

|

#25 |

|

Registered User

Join Date: Sep 2016

Location: Redington Beach

Posts: 1,317

|

Re: Depinned engine harness --- now ... ??

Thats awesome

I might PM you at sometime on the fusing. For right now I plan to Run the PCM wherever it fits best but hopefully to drivers side inner fender. Run the TAC module to same location. Build a multi relay setup as https://www.youtube.com/watch?v=BvFHA1xY10w and also place on inner fender. AC wiring and truck EZ wiring inside cab. This being my first build Im less concerned on cosmetics. Still want it to be nice but after 2 years more important to actually get it running than spend extra weeks worrying about that level of detail. Round #2 might be a bit different

__________________

FAKKY 57 PANEL BUILD |

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|