|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Registered User

Join Date: Dec 2008

Location: Las Vegas, NV

Posts: 811

|

Always a project truck...............my driveway build

pulled the trigger, parts are ordered! No going back now.

Going to address the suspension first on this build Parts List: 1. Belltech 4/6 drop kit with Street Performance Shocks(3" spindles/1" springs/flip kit/c-notch) 2. Porterbuilt 1" forward tubular lower control arms/delrin bushings/ for stock coil spring application(centers front wheel in wheel opening correcting the known visual flaw when lowered/adds castor gain of approx 7 deg) 3. Stock upper control arms with MOOG K6184 problem solver control arm shafts/bushing kit(allows additional positive camber adjustment) 4. Stock rear leaf springs and shackle w/Energy suspension bushings(have run these before and like them alot) 5. Energy suspension body mounts 6. McGaughy's 12.5" Front Disc Brake Kit part# 63156 7. MOOG tie rods/adjustment sleeve/idler/pitman arm/ball joints 8. Dorman lower control arm u-bolts Should be a good start to a nice riding truck!!

__________________

1983 Chevy C10 250/3spd (current project truck) 1976 Chevy C10 350/350 Heavy Half (future project truck) Last edited by moregrip; 08-11-2013 at 11:41 AM. |

|

|

|

|

|

#2 |

|

Registered User

Join Date: Dec 2008

Location: Las Vegas, NV

Posts: 811

|

Re: Always a project truck...............my driveway build

Few updates:

Sent the McGaughys's front brake kit back (it was not the 12.5" kit advertised but a stock rotor diameter kit). No worries, going to source my own parts, Raybestos professional line and Timken bearings/seals. Going with Dorman Spindle nuts and washers as I couldn't find another source for those. Hopefully of the same "made in the USA" quality as their lower control arm u-bolts. Looking for a good carb re-builder for the 1 barrel monojet, any leads? Received the Belltech 4/6 drop kit.....all checks out.

__________________

1983 Chevy C10 250/3spd (current project truck) 1976 Chevy C10 350/350 Heavy Half (future project truck) |

|

|

|

|

|

#3 |

|

Registered User

Join Date: Dec 2008

Location: Las Vegas, NV

Posts: 811

|

Re: Always a project truck...............my driveway build

update #2 (real time)

I don't know what I hate more.......the wax coating GM puts on the frame of the new stuff.........or...........40yrs of dirt and grease! Got a few things accomplished yesterday. The main thing I wanted to get done was remove the girder beam up front(accomplished). Thank GOD for penetrating oil(but damn that stuff stinks)!!! Setting piles aside for solvent tank cleaning and blasting! No fancy powder coat for this one............ driveway DIY all the way!

__________________

1983 Chevy C10 250/3spd (current project truck) 1976 Chevy C10 350/350 Heavy Half (future project truck) Last edited by moregrip; 08-11-2013 at 11:55 AM. |

|

|

|

|

|

#4 |

|

Registered User

Join Date: Sep 2012

Location: Midway, NC

Posts: 3,275

|

Re: Always a project truck...............my driveway build

I'm watching this one for sure. Got to let us know how all this stuff goes.!

__________________

http://67-72chevytrucks.com/vboard/s...d.php?t=581873 The low buck build threads. Check'em out! http://67-72chevytrucks.com/vboard/s...d.php?t=666022 My build thread Crossmembers CC |

|

|

|

|

|

#5 | |

|

Registered User

Join Date: Dec 2008

Location: Las Vegas, NV

Posts: 811

|

Re: Always a project truck...............my driveway build

Quote:

got a little more quality time with the cleaning supplies today

__________________

1983 Chevy C10 250/3spd (current project truck) 1976 Chevy C10 350/350 Heavy Half (future project truck) |

|

|

|

|

|

|

#6 |

|

Registered User

Join Date: Jan 2010

Location: Brandon, Manitoba, Canada

Posts: 782

|

Re: Always a project truck...............my driveway build

subscribed for sure....

__________________

1967 K30 4x4/12v Cummins/getrag/D60/D70/355s 1967 GMC suburban 4x4/LS swap 5.3/4500/205/10 bolt/14 bolt full floater 1963 C10 reg cab long box 1970 Chevelle 1968 Biscayne 2dr post "...there is no excuse for what I am about to do, but dangit....it's gonna be fun!" |

|

|

|

|

|

#7 |

|

Registered User

Join Date: Dec 2008

Location: Las Vegas, NV

Posts: 811

|

Re: Always a project truck...............my driveway build

couple of updates:

1. I talked with Tom Langdon about my integrated head situation and some of the issues I was experiencing. He recommending adding a few degrees of timing(which I did). That helped out tremendously but with such a high failure(cracking) rate at it's current life cycle I am torn between just installing a rebuilt carb(less money now) or switching to a non integrated head/intake/carb/header setup (obviously more $$ upfront) 2. Still waiting for all the parts to show up. Although I did take delivery on some chassis paint(good news). 3. Need to finish up on all my piles of the parts I will refurb vs replace. Going slower than expected of course. that's about it for now! stay tuned!

__________________

1983 Chevy C10 250/3spd (current project truck) 1976 Chevy C10 350/350 Heavy Half (future project truck) |

|

|

|

|

|

#8 |

|

Registered User

Join Date: Jun 2004

Location: Spartanburg, SC

Posts: 1,963

|

Re: Always a project truck...............my driveway build

cool build, hope your keeping the I6! If you want solid tierod adjuster sleeves look at edelbrock part number 5252. I just used a set on my front end rebuild. I think they were about $50 though....

__________________

Paul '78 GMC Serria 15 Heavy Half. 361/NV3500/3.73. Former LWB NV3500 swap Trailing arm swap '98 ECSB Z71 daily driver -traded  '03 burb. Family cruiser http://upstategmtrucks.com/ |

|

|

|

|

|

#9 |

|

Registered User

Join Date: Mar 2012

Location: San Antonio, Tx

Posts: 784

|

Re: Always a project truck...............my driveway build

hope fully they dont take 2 months with those control arms like they did with mine, but they sure are nice do!

__________________

San Antonio, TEXAS -Frog -I'm a valet and well I've driven BMWs, Mercedes, Porsche,Bentlys, fiats, Hondas, etc and well even do I like a few features, I love my shortbed, it dosent bore me out, just press on the gas and you'll remember why you love it. |

|

|

|

|

|

#10 | |

|

Registered User

Join Date: Dec 2008

Location: Las Vegas, NV

Posts: 811

|

Re: Always a project truck...............my driveway build

Quote:

thanks for the tip on the adjuster sleeves (already bought Moog). thanks for the tip on the adjuster sleeves (already bought Moog).going to try this out on some, if not most, of the suspension pieces and front frame(what I can access anyway)

__________________

1983 Chevy C10 250/3spd (current project truck) 1976 Chevy C10 350/350 Heavy Half (future project truck) |

|

|

|

|

|

|

#11 | |

|

Registered User

Join Date: Dec 2008

Location: Las Vegas, NV

Posts: 811

|

Re: Always a project truck...............my driveway build

Quote:

edit: Fel Pro gasket set showed up damaged, re sending(another 4 days on that)

__________________

1983 Chevy C10 250/3spd (current project truck) 1976 Chevy C10 350/350 Heavy Half (future project truck) |

|

|

|

|

|

|

#12 |

|

Registered User

Join Date: Sep 2012

Location: Midway, NC

Posts: 3,275

|

Re: Always a project truck...............my driveway build

Inline sixes can be built fairly cheap. As for cracking if you are worried about it doing so in the front of the block. You can, sometimes, drill it and put a pin or small bolt in it to stop it. Did this on our race car many years ago and held up very good. The motor spun to 6500 rpms. So these motors can take right much abuse. I say spend the money up front and enjoy some of the fruits. I know our motor in our race car spends now close to 7000 rpms. Crazy I know but that's on a stock bottom end. These motors are cool.

__________________

http://67-72chevytrucks.com/vboard/s...d.php?t=581873 The low buck build threads. Check'em out! http://67-72chevytrucks.com/vboard/s...d.php?t=666022 My build thread Crossmembers CC |

|

|

|

|

|

#13 | |

|

Registered User

Join Date: Dec 2008

Location: Las Vegas, NV

Posts: 811

|

Re: Always a project truck...............my driveway build

Quote:

Do you have any links or pics you'd be willing to share? Thanks! Do you have any links or pics you'd be willing to share? Thanks!lookie what showed up today! from other pics of PB 73-87 lower A-Arms, design may have changed a bit

__________________

1983 Chevy C10 250/3spd (current project truck) 1976 Chevy C10 350/350 Heavy Half (future project truck) Last edited by moregrip; 08-15-2013 at 08:31 PM. |

|

|

|

|

|

|

#14 |

|

Registered User

Join Date: Dec 2008

Location: Las Vegas, NV

Posts: 811

|

Re: Always a project truck...............my driveway build

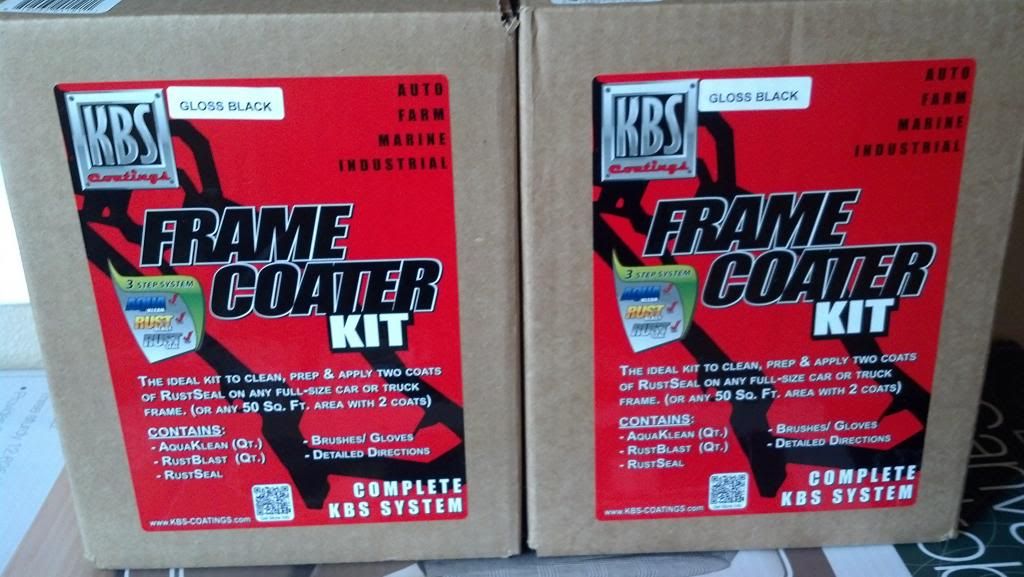

got some cleanup work done on the cross-member. ground down any welding slag, deburred all knife edges, spending the day getting some more rust removed, then give this KBS coating system a try:

I bought this truck on ebay and all was as described with the exception of the drivers side leading edge of the frame being slightly bent. What methods have others(you) used to fix this? looks like the damage(impact point) came from just below the drivers side frame rail height heading up and inward(mostly inward), top edge of the frame is kinked upwards as a result, side of frame rail is bent inward.  thinking about making a couple of relief cuts(easier to bend frame), straightening the frame, then welding the seams shut, thoughts? edit: if anyone has a drivers side to passenger side 1/2 ton frame rail to frame rail measurement on a straight frame handy I'd sure appreciate it! just need to know where you took your measurement from

__________________

1983 Chevy C10 250/3spd (current project truck) 1976 Chevy C10 350/350 Heavy Half (future project truck) Last edited by moregrip; 08-17-2013 at 10:56 AM. |

|

|

|

|

|

#15 | |

|

Registered User

Join Date: Apr 2001

Location: DALLAS,TX

Posts: 22,066

|

Re: Always a project truck...............my driveway build

Quote:

Factory specs call for around +.5 positive camber w/minimal tire wear issues. Target -.5 camber for better corner grip. Positive camber allows for 'push' or oversteer in corners which gets the average driver to slow down. Negative camber allows for more tire patch contact when cornering.

__________________

67SWB-B.B.RetroRod 64SWB-Recycle 89CCDually-Driver/Tow Truck 99CCSWB Driver All Fleetsides @rattlecankustoms in IG Building a small, high rpm engine with the perfect bore, stroke and rod ratio is very impressive. It's like a highly skilled Morrocan sword fighter with a Damascus Steel Scimitar..... Cubic inches is like Indiana Jones with a cheap pistol. |

|

|

|

|

|

|

#16 | |

|

Registered User

Join Date: Dec 2008

Location: Las Vegas, NV

Posts: 811

|

Re: Always a project truck...............my driveway build

Quote:

I know it's petty, but I just don't like seeing 1/2" worth of shims.

__________________

1983 Chevy C10 250/3spd (current project truck) 1976 Chevy C10 350/350 Heavy Half (future project truck) Last edited by moregrip; 08-17-2013 at 12:03 PM. |

|

|

|

|

|

|

#17 | |

|

Registered User

Join Date: Sep 2012

Location: Midway, NC

Posts: 3,275

|

Re: Always a project truck...............my driveway build

Quote:

Check inliners.org they used to have some good stuff. I'm guessing they are still around. There are several books available as well. You'd be surprised at what internally is interchangeable. Our block were always 230cid with a 194 head. Meaning a head off a 194 cid block. They were basically rebuilt heads with good valve stems and roller rockers on top. There's some machining to do but it can't hurt to study up on these. Flow isn't great with stock heads but you can do more than our class allowed. As for the bottom ends go we ran stock 230 cranks. Aftermarket rods. I think we used to use rods for a 283 cid V8. Here again you have more opportunity to improve. ARP rod bolts. We used to run a single barrel carb. That thing would flow. Then they allowed us to go to a 2bbl. Which helped right much. These motors don't need a whole lot of carb as we found out. We ran a 350cfm Holley with good results, but a good Edelbrock carb two or four and a Clifford or Offenhauser intake would be good. Set of headers if they will work with the lowering of your truck. You can just rebuild and be happy too. Hope this helps.

__________________

http://67-72chevytrucks.com/vboard/s...d.php?t=581873 The low buck build threads. Check'em out! http://67-72chevytrucks.com/vboard/s...d.php?t=666022 My build thread Crossmembers CC |

|

|

|

|

|

|

#18 | |

|

Registered User

Join Date: Dec 2008

Location: Las Vegas, NV

Posts: 811

|

Re: Always a project truck...............my driveway build

Quote:

__________________

1983 Chevy C10 250/3spd (current project truck) 1976 Chevy C10 350/350 Heavy Half (future project truck) |

|

|

|

|

|

|

#19 |

|

Registered User

Join Date: Dec 2009

Location: Windsor, Ontario

Posts: 78

|

Re: Always a project truck...............my driveway build

If your looking for some upper control arms for your build, look at Michigan Metal Works flat stock upper's, they had a deal with free shipping this weekend, I ordered a set for $149.

|

|

|

|

|

|

#20 | |

|

Registered User

Join Date: Dec 2008

Location: Las Vegas, NV

Posts: 811

|

Re: Always a project truck...............my driveway build

Quote:

I think I have $150 in parts just to rebuild those things I think I have $150 in parts just to rebuild those things  I have a decent pile of parts I'm taking on base tomorrow, going to clean all I can in their blast cabinet  It's good to have an auto hobby shop to use from time to time It's good to have an auto hobby shop to use from time to time

__________________

1983 Chevy C10 250/3spd (current project truck) 1976 Chevy C10 350/350 Heavy Half (future project truck) |

|

|

|

|

|

|

#21 |

|

Registered User

Join Date: Dec 2008

Location: Las Vegas, NV

Posts: 811

|

Re: Always a project truck...............my driveway build

spent some time in front of the blasting cabinet today.......took way longer than I thought it would. Round one down, two or three more to go, I suspect!!

__________________

1983 Chevy C10 250/3spd (current project truck) 1976 Chevy C10 350/350 Heavy Half (future project truck) |

|

|

|

|

|

#22 |

|

Registered User

Join Date: Jul 2009

Location: washington

Posts: 4,178

|

Re: Always a project truck...............my driveway build

Pie rule. Everything takes 3.14 times longer than expected to complete

Posted via Mobile Device

__________________

377 sbc thumpr cam autogear m23 muncie 3:73 Detroit trutrac 3''spintech prostreet mufflers xpipe 1 3/4 headers build thread !http://67-72chevytrucks.com/vboard/s...d.php?t=577217 Iroc gauge threadhttp://67-72chevytrucks.com/vboard/s...d.php?t=554511 |

|

|

|

|

|

#23 | |

|

Registered User

Join Date: Dec 2008

Location: Las Vegas, NV

Posts: 811

|

Re: Always a project truck...............my driveway build

Quote:

on another note, after returning the McGaughys brake kit I sourced my own brake parts. Most of them come from Raybestos professional line (calipers, rotors, flex lines). Used the Raybestos Advanced Technology Ceramic brake pads. Many years ago I worked at a Texaco gas station and the owner who I respect quite a bit, swore by Raybestos. Going to add power brakes vs the stock manual brakes; Tuff Stuff master cylinder/power brake boost combo and Right Stuff Detailing front brake hardline kit and proportioning valve. Using Timken bearings and seals. Please feel free to critique/offer advice, and thanks.

__________________

1983 Chevy C10 250/3spd (current project truck) 1976 Chevy C10 350/350 Heavy Half (future project truck) |

|

|

|

|

|

|

#24 |

|

Registered User

Join Date: Dec 2008

Location: Las Vegas, NV

Posts: 811

|

Re: Always a project truck...............my driveway build

__________________

1983 Chevy C10 250/3spd (current project truck) 1976 Chevy C10 350/350 Heavy Half (future project truck) |

|

|

|

|

|

#25 |

|

Registered User

Join Date: Dec 2008

Location: Las Vegas, NV

Posts: 811

|

Re: Always a project truck...............my driveway build

round 2 complete. cleaned up the motor mount brackets, upper control arm shaft washers/hardware, fan, carb linkage bracket, etc. did a little rework on the UCA's as well. enjoy:

__________________

1983 Chevy C10 250/3spd (current project truck) 1976 Chevy C10 350/350 Heavy Half (future project truck) |

|

|

|

|

| Bookmarks |

|

|