|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#26 |

|

It's Better With Nitro

Join Date: Apr 2008

Location: Chino Hills, CA

Posts: 2,262

|

Re: step cont arms or drop spindles....

Yes, a dropped spindle has the engineering done for you. Here's a link to what I was talking about (CPP drop spindle and stock spindle photo side by side). http://www.classicperform.com/Store/...ruck/CP4S1.htm

If you were to move the stock spindle up 2 inches via a stepped lower control arm, the steering arm location would also move up 2 inches. This means the angle of the tie rod attachment to the steering arm would would increase up toward the spindle - this would significantly change the angle of the tie end rod in relation to the lower control arm angle. Even slight changes in steering geometry can have severe affects on handling and bump steer conditions.

__________________

1963 C-10: Deluxe-optioned cab, shortbed, fleetside Pontiac 462 ci, Kauffman D-Port alum. heads 4L80E, narrowed sheetmetal Ford 9-inch Tubular front and rear suspension Custom 6-piston front disc and 4-piston rear disc brakes |

|

|

|

|

#27 | |

|

Double 6's

Join Date: Oct 2008

Location: Winter Haven, FL

Posts: 349

|

Re: step cont arms or drop spindles....

Quote:

|

|

|

|

|

|

#28 | |

|

Registered User

Join Date: Nov 2008

Location: Windsor, CA

Posts: 500

|

Re: step cont arms or drop spindles....

Quote:

__________________

If you can find it cheaper, I can fix it! |

|

|

|

|

|

#29 |

|

It's Better With Nitro

Join Date: Apr 2008

Location: Chino Hills, CA

Posts: 2,262

|

Re: step cont arms or drop spindles....

If you are stepping a lower control arm to lower the vehicle, not all of the pivot points will be the same - otherwise the ride height of the vehicle would not change. If you cannot understand that the tie end rod moves on a separate axis, and therefore a different arc of travel, independent from the control arms, then you're going to have problems setting up your front suspension without bump steer. The steering geometry changes when raising the spindle assembly higher without compensating for the tie rod angle - you'll need some sort of bump steer adjuster/shim to lower the tie rod angle. There are three arcs of travel working: upper control arm, lower control arm and the tie rod - changing one changes the geometry.

__________________

1963 C-10: Deluxe-optioned cab, shortbed, fleetside Pontiac 462 ci, Kauffman D-Port alum. heads 4L80E, narrowed sheetmetal Ford 9-inch Tubular front and rear suspension Custom 6-piston front disc and 4-piston rear disc brakes |

|

|

|

|

#30 | |

|

Registered User

Join Date: Apr 2001

Location: DALLAS,TX

Posts: 22,066

|

Re: step cont arms or drop spindles....

Quote:

But, (& this is pure speculation, but worth investigating). . ... If one were to move the steering arm 2", it might be possible to relocate the tie-rod end tp the opposite side of where it originally attached to the spindle. Then you might be able to adjust the bumpsteer issue from there w/typical 'mis-alignment' bushings (aka heim-joints).

__________________

67SWB-B.B.RetroRod 64SWB-Recycle 89CCDually-Driver/Tow Truck 99CCSWB Driver All Fleetsides @rattlecankustoms in IG Building a small, high rpm engine with the perfect bore, stroke and rod ratio is very impressive. It's like a highly skilled Morrocan sword fighter with a Damascus Steel Scimitar..... Cubic inches is like Indiana Jones with a cheap pistol. |

|

|

|

|

|

#31 | |

|

Registered User

Join Date: Nov 2008

Location: Windsor, CA

Posts: 500

|

Re: step cont arms or drop spindles....

Quote:

Basically I am trying to say that your suspension simply see's the bushing and ball joint/tie rod pivots. The control arm shape does not matter. I still prefer spindles as the first form of suspension alteration.

__________________

If you can find it cheaper, I can fix it! |

|

|

|

|

|

#32 |

|

Senior Member

Join Date: Dec 2003

Location: Mesa,Az

Posts: 3,981

|

Re: step cont arms or drop spindles....

As Twisted has mentioned several times, and even clarified with a drawering... the negative effects on the geometry do not come from the actually stepping of the arm. If the arm is stepped to where the ball joint is moved up 2" (and it maintains the same distance between the control arm pivots) it will yield the same results as putting in a 2" drop spring. The steering arms and outer tie-rod pivot would find themsleves in the same positions with either a 2" step, or a 2" drop spring. What happens, with either method, is that as the suspension is compressed, the steering and suspension arcs are reaching points where their changes become more drastic and camber curves, and bumpsteer are more greatly effected.

__________________

www.PorterbuiltFabrication.com Phone: 480-297-2621 E-mail: sales@pbfab.com Find us on FaceBook under Porterbuilt Fabrication Specializing in Chassis and Suspension Components for your Classic Chevrolet Truck. We offer components from the following manufacturers: Porterbuilt Accuair Ridetech (Air Ride Technologies) Air Lift Wilwood Intro Unisteer ECE Gotta Show Air Lift Borgeson CPP Supporting this forum since 2003! |

|

|

|

|

#33 |

|

It's Better With Nitro

Join Date: Apr 2008

Location: Chino Hills, CA

Posts: 2,262

|

Re: step cont arms or drop spindles....

Your illustrations proves my point...interesting how the tie rod angle in relation to the spindle in the stepped illustration is lower than the stock and lowered illustrations - you have the tie rod end at different locations at the spindle (with the tie rod end nearly parallel to the bottom of the spindle in the stepped illustraion).

This does not happen unless you change the tie rod mount at the spindle. So, this must mean you are changing the mount location of the tie rod by either changing the steering knuckle/arm on the spindle, or using a bump steer adjuster? This does not happen unless you change the tie rod mount at the spindle. So, this must mean you are changing the mount location of the tie rod by either changing the steering knuckle/arm on the spindle, or using a bump steer adjuster?

__________________

1963 C-10: Deluxe-optioned cab, shortbed, fleetside Pontiac 462 ci, Kauffman D-Port alum. heads 4L80E, narrowed sheetmetal Ford 9-inch Tubular front and rear suspension Custom 6-piston front disc and 4-piston rear disc brakes Last edited by vin63; 02-10-2009 at 09:56 AM. |

|

|

|

|

#34 |

|

Registered User

Join Date: Nov 2008

Location: Windsor, CA

Posts: 500

|

Re: step cont arms or drop spindles....

Okay ya the pivot isn't in the same spot, it's because I did not draw them correctly.

I guess I will not be able to convince you. Stepping the control arm DOES NOT change the spindle. Here I modified the drawing to be correct as I intended originally.

__________________

If you can find it cheaper, I can fix it! Last edited by Twisted Minis; 02-10-2009 at 01:09 PM. |

|

|

|

|

#35 |

|

It's Better With Nitro

Join Date: Apr 2008

Location: Chino Hills, CA

Posts: 2,262

|

Re: step cont arms or drop spindles....

Here's a better illustration with my front suspension at full drop. And, stepping a control arm or adding a ball joint spacer (old school) does move the spindle higher, which lowers the suspension - which is what you are trying to do, right? What you're not taking into account is that the steering arm is attached to the spindle. See below.

In this photo, the spindle is mounted directly onto the ball joint and the tie rod is located on a parallel plane about 4 inches above the lower control arm plane - both running slightly up hill in the photo since the air spring is deflated and resting on the bump stop.  In this photo, I removed the castle nut on the lower ball joint and moved the spindle and tire/wheel assembly up just 1.5 inches to simulate a ball joint spacer or stepped lower control arm (note the height difference of the bottom of the spindle). You'll see that the angle of the tie rod has changed significantly and is now running more up hill compared to the plane of the lower control to a point about 5.5 inches higher than the lower control arm.  In this second scenario, if the suspension traveled down, the tie rod would start to push out the steering arm (toe out) as the tie rod started to reach horizontal - the apex of the tie rod's arc of travel. This would cause bump steer (you can even see that in the bottom photo, the angle of the tire rod has pulled in the tire/wheel compared to the first photo). Imagine the increase in tie rod angle difference if the step was 1 inch higher for a 2.5 inch step.

__________________

1963 C-10: Deluxe-optioned cab, shortbed, fleetside Pontiac 462 ci, Kauffman D-Port alum. heads 4L80E, narrowed sheetmetal Ford 9-inch Tubular front and rear suspension Custom 6-piston front disc and 4-piston rear disc brakes Last edited by vin63; 02-10-2009 at 04:25 PM. |

|

|

|

|

#36 | |

|

It's Better With Nitro

Join Date: Apr 2008

Location: Chino Hills, CA

Posts: 2,262

|

Re: step cont arms or drop spindles....

Quote:

__________________

1963 C-10: Deluxe-optioned cab, shortbed, fleetside Pontiac 462 ci, Kauffman D-Port alum. heads 4L80E, narrowed sheetmetal Ford 9-inch Tubular front and rear suspension Custom 6-piston front disc and 4-piston rear disc brakes |

|

|

|

|

|

#37 | |

|

Senior Member

Join Date: Dec 2003

Location: Mesa,Az

Posts: 3,981

|

Re: step cont arms or drop spindles....

Quote:

By the pictures you have posted, it is obvious to me, that we have a different viewpoint of what "stepping" the control arm is. I think that once we clarify this point we can all be buddies again! My definition of "stepping" the control arm is when the ball joint of the lower control arm is relocated to a position an inch or two higher, and then the arm is boxed around the raised ball joint. This has ZERO effect on spindle height. So in essence, the spindle and steering's geometry has not been altered. In your second picture, you have lengthened the spindle's height... causing GREAT changes and multiple issues would arise. If you were to take a ball joint and screw it into the spindle (in your second pic) then box it back into the lower arm it would yield the same result as compressing the suspension that same two inches via a drop-coil or deflated air spring. If I didn't do a thorough enough job explaining, please let me know. If you're attacking my expertise or credentials due to a "misunderstanding" an apology will be just fine. As I mentioned earlier, I believe we are just misinterpreting one another's idea of "stepping" the lower arm.

__________________

www.PorterbuiltFabrication.com Phone: 480-297-2621 E-mail: sales@pbfab.com Find us on FaceBook under Porterbuilt Fabrication Specializing in Chassis and Suspension Components for your Classic Chevrolet Truck. We offer components from the following manufacturers: Porterbuilt Accuair Ridetech (Air Ride Technologies) Air Lift Wilwood Intro Unisteer ECE Gotta Show Air Lift Borgeson CPP Supporting this forum since 2003! |

|

|

|

|

|

#38 | |

|

It's Better With Nitro

Join Date: Apr 2008

Location: Chino Hills, CA

Posts: 2,262

|

Re: step cont arms or drop spindles....

Quote:

__________________

1963 C-10: Deluxe-optioned cab, shortbed, fleetside Pontiac 462 ci, Kauffman D-Port alum. heads 4L80E, narrowed sheetmetal Ford 9-inch Tubular front and rear suspension Custom 6-piston front disc and 4-piston rear disc brakes |

|

|

|

|

|

#39 | |

|

Senior Member

Join Date: Dec 2003

Location: Mesa,Az

Posts: 3,981

|

Re: step cont arms or drop spindles....

Quote:

Vin- Don't worry... I am about the most patient guy you'll ever meet, and I am doing my best to help you understand this. After each post, I am seeing your perspective a little more clearly. I have to get some more things done in the shop, and will have to come back to this a little later! I will do some illustrations to help clarify.

__________________

www.PorterbuiltFabrication.com Phone: 480-297-2621 E-mail: sales@pbfab.com Find us on FaceBook under Porterbuilt Fabrication Specializing in Chassis and Suspension Components for your Classic Chevrolet Truck. We offer components from the following manufacturers: Porterbuilt Accuair Ridetech (Air Ride Technologies) Air Lift Wilwood Intro Unisteer ECE Gotta Show Air Lift Borgeson CPP Supporting this forum since 2003! |

|

|

|

|

|

#40 | |

|

It's Better With Nitro

Join Date: Apr 2008

Location: Chino Hills, CA

Posts: 2,262

|

Re: step cont arms or drop spindles....

Quote:

__________________

1963 C-10: Deluxe-optioned cab, shortbed, fleetside Pontiac 462 ci, Kauffman D-Port alum. heads 4L80E, narrowed sheetmetal Ford 9-inch Tubular front and rear suspension Custom 6-piston front disc and 4-piston rear disc brakes |

|

|

|

|

|

#41 |

|

Happy to be here

Join Date: Mar 2000

Location: Cypress, TX

Posts: 39,021

|

Re: step cont arms or drop spindles....

I really appreciate you experts keeping this a positive conversation....

__________________

Follow me on Facebook and Instagram @N2trux.com Articles- "Jake" the 84 to 74 crewcab "Elwood" the77_Remix 85 GMC Sierra "Scarlett" "Refining Sierra" |

|

|

|

|

#42 |

|

Argon User

Join Date: Oct 2008

Location: Qc, AZ

Posts: 353

|

Re: step cont arms or drop spindles....

I like to say I agree with Seth and Nathan......................

|

|

|

|

|

#43 |

|

Registered User

Join Date: Nov 2008

Location: Windsor, CA

Posts: 500

|

Re: step cont arms or drop spindles....

Like Nathan said, I think we have two different definitions of stepping a control arm. I see it the same way he does, move the ball joint itself up, in relation to the control arm, but do not move it in relation to the spindle. What you illustrated with your pictures, would be moving the spindle in relation to the ball joint, which will most definitely change your geometry vastly. And on most vehicles it will not have a positive effect. HOWE makes ball joints with a taller shaft to do what you are describing.

Here is a control arm I built for a car, that was designed to move the ball joint up in relation to the control arm, because the control arm was hitting the frame.   On the stock control arm, the ball joint was in line with the tubes. I used a large cup to move the ball joint up 1.5 inches. The spindle still sits on the ball joint the same way it would on a stock control arm, the only difference is the ball joint is 1.5" higher than the control arm now. The tie rods still mounted in the same fashion as well, and it still has stock geometry. Only now the control arm isn't holding the car up by hitting the frame.

__________________

If you can find it cheaper, I can fix it! |

|

|

|

|

#44 |

|

Registered User

Join Date: Dec 2007

Location: Palmer, Alaska

Posts: 13,821

|

Re: step cont arms or drop spindles....

ditto, the relation between the arc of the lower control arm and the arc of the tie rod remain the same....

__________________

CHEVY ONLY CHEVY ONLY

|

|

|

|

|

#45 |

|

Registered User

Join Date: Jun 2008

Location: pensacola fl

Posts: 3,073

|

Re: step cont arms or drop spindles....

wow... I am learning so much right now. I can respect those who's expertise in this matter are evident in how strongly they belive in what they do or know.

Thanks and i agree with n2trux. |

|

|

|

|

#46 | |

|

It's Better With Nitro

Join Date: Apr 2008

Location: Chino Hills, CA

Posts: 2,262

|

Re: step cont arms or drop spindles....

Quote:

It's really semantics...you're either moving the spindle up to lower the vehicle, or you're not. If the ball joint location on the lower control arm is higher, the spindle and steering arm will be located higher relative to the control arm, as well - that's just physics. Your photos of the control arm do no show the spindle and steering arm before and after. It can't be that complicated. I've worked at alignment shops, I've built race cars and have installed ball joint spacer kits and stepped lower control arms to raise the ball joint location...and in each instance the kit comes with a corresponding spacer for the tie rod or I've had to use a bump steer adjuster to locate it lower to adjust for the increase in height of the spacer or step. Please show me the difference between what you guys are referring to versus what I've photographed and posted. I would love to see what you guys are talking about and how the steering in your cases are not altered. Thanks.

__________________

1963 C-10: Deluxe-optioned cab, shortbed, fleetside Pontiac 462 ci, Kauffman D-Port alum. heads 4L80E, narrowed sheetmetal Ford 9-inch Tubular front and rear suspension Custom 6-piston front disc and 4-piston rear disc brakes |

|

|

|

|

|

#47 |

|

Senior Member

Join Date: Dec 2003

Location: Mesa,Az

Posts: 3,981

|

Re: step cont arms or drop spindles....

Vin-

I apologize for not following through on the "illustrations". I layed down on the couch a few hours ago... and somehow missed out on most of the evening! From your last statement describing how you would help with the drag cars and modify the suspension by adding ball joint spacers it seems to me that is where the miscommunication lies. When you step the control arm you are in essence lowering the spring cup to achieve drop. Or in the example that Twisted just posted, modifying the shape of the arm for clearance. The pivot point in relation to the spindle does not change, nor does the height of the spindle. The suspension geometry is defined by center to center locations in the x,y,and z axis of the pivot points of the suspension, not the shape of the linkage that holds those pivot points in space. A classis example of a suspension mod that is similar to what you maybe confusing this with would be the ball joint spacers used on the upper ball joint in early camaros. This mod would effectively increase the height of the spindle,which would yield more camber gain. It was the cheap and easy fix to achieve similar results as the Guldstrand Mod. By stepping the control arm, it does not change the ball joint's or steering joint's relation to the spindle. All it really does is lower the spring pocket. Let me know if I still need to post up some illustrations... they would not be much different than what has already been posted. But maybe they could help?

__________________

www.PorterbuiltFabrication.com Phone: 480-297-2621 E-mail: sales@pbfab.com Find us on FaceBook under Porterbuilt Fabrication Specializing in Chassis and Suspension Components for your Classic Chevrolet Truck. We offer components from the following manufacturers: Porterbuilt Accuair Ridetech (Air Ride Technologies) Air Lift Wilwood Intro Unisteer ECE Gotta Show Air Lift Borgeson CPP Supporting this forum since 2003! |

|

|

|

|

#48 |

|

Registered User

Join Date: Nov 2008

Location: Windsor, CA

Posts: 500

|

Re: step cont arms or drop spindles....

What you posted is spacing the spindle away from the ball joint. What I posted is spacing the ball joint away from the control arm. The ball joint and tie rod still retain the same amount of separation as they did before. I unfortunately do not have before/after pictures to show you, or pictures with the spindle on. I did not take any.

What I did does move the spindle up to lower the vehicle, in relation to the control arm itself. It pushed the ball joint up in relation to the arm, because the arm hit the frame. It lowered the car 1.5 inches, but the ball joint did not move in relation to the spindle or the tie rod. The ball joint still seats into the spindle, same as stock, and so does the tie rod, so their relationship is still un-changed. And the pivot points on the frame side where also not altered, leaving them the same. If none of these pivots where changed, then the steering geometry was not altered. The control arm is just taking a new shape to provide clearance for the frame. I feel like I am repeating myself now. Lol. Hopefully we can get through this.

__________________

If you can find it cheaper, I can fix it! Last edited by Twisted Minis; 02-11-2009 at 01:16 AM. |

|

|

|

|

#49 |

|

Registered User

Join Date: Nov 2008

Location: Windsor, CA

Posts: 500

|

Re: step cont arms or drop spindles....

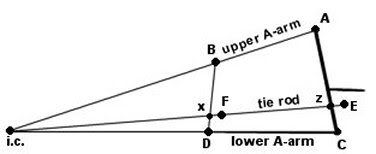

Here is a good diagram that shows the pivot points of a front suspension. What I am trying to say, is that these pivot points don't change if you change the shape of the control arm.

__________________

If you can find it cheaper, I can fix it! |

|

|

|

|

#50 |

|

Senior Member

Join Date: Dec 2003

Location: Mesa,Az

Posts: 3,981

|

Re: step cont arms or drop spindles....

Vin-

I just read your last post and have some more information that may prove useful. The reason those kits come with the shims or spacers for the outer tie rod is to help alleviate the bumpsteer that is induced due to the change in the static suspension height. None of the suspension's pivots have changed in relation to the spindle, but due to the tighter arcs created by the compressed suspension, bumpsteer becomes more prominent.

__________________

www.PorterbuiltFabrication.com Phone: 480-297-2621 E-mail: sales@pbfab.com Find us on FaceBook under Porterbuilt Fabrication Specializing in Chassis and Suspension Components for your Classic Chevrolet Truck. We offer components from the following manufacturers: Porterbuilt Accuair Ridetech (Air Ride Technologies) Air Lift Wilwood Intro Unisteer ECE Gotta Show Air Lift Borgeson CPP Supporting this forum since 2003! |

|

|

|

| Bookmarks |

|

|