|

|

|

#151 |

|

Registered User

Join Date: Jul 2012

Location: Jonestown, TX

Posts: 471

|

Re: TCI to start new R&D Project with a C10!

Schwing!! haha

|

|

|

|

|

|

#152 |

|

Registered User

Join Date: May 2007

Location: Deale Md

Posts: 4,663

|

Re: TCI to start new R&D Project with a C10!

twins are every one fantasy

__________________

James 63 GMC V6 4speed carryall 65 chevy swb bbw V8 auto 68 K20 327/4 speed, buddy buckets 2002 GMC CC Dually Duramax 64 GMC lwb 3/4 V6 4speed SOLD 66 GMC swb bbw buddy buckets SOLD IG duallyjams The only thing that stays the same is constant change! |

|

|

|

|

|

#153 |

|

Registered User

Join Date: Mar 2011

Location: SoCal

Posts: 151

|

Re: TCI to start new R&D Project with a C10!

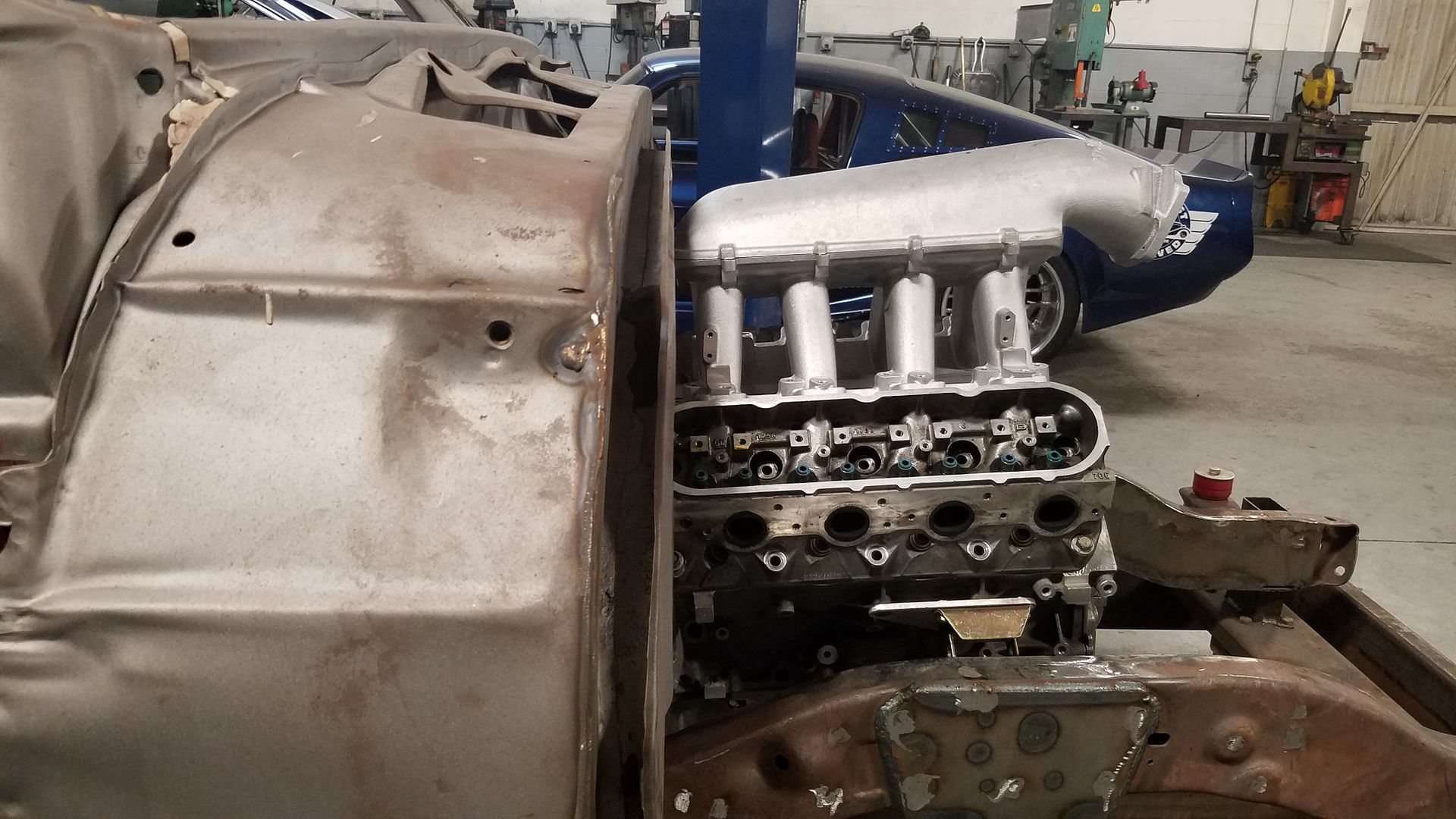

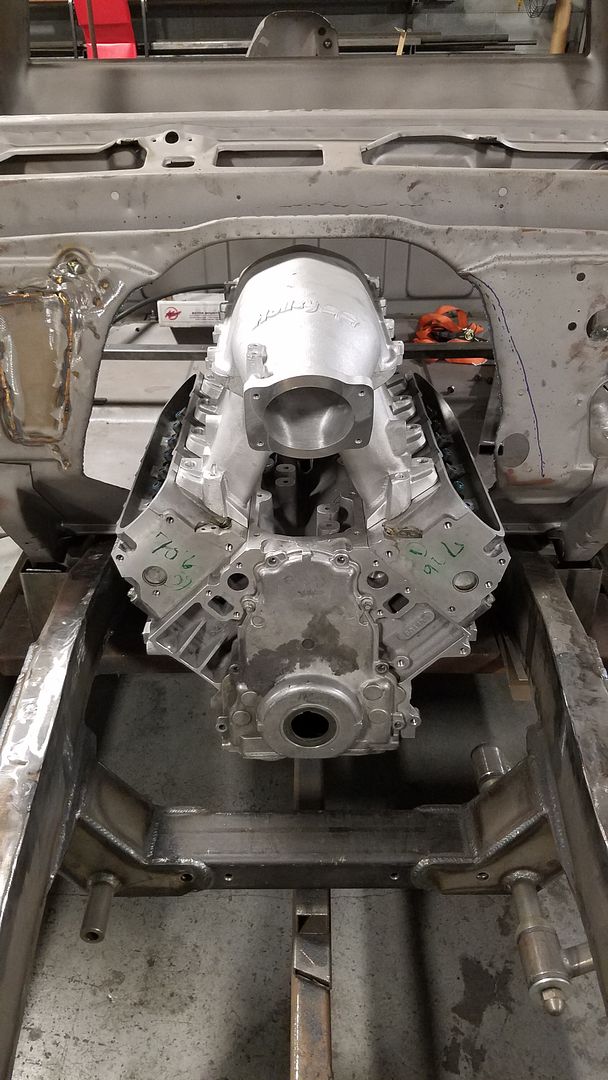

Mounting the ballast.... Since the bed wasn't mounted yet I just took a guess on where they should be based off the factory cab mounts.

Came pretty close on my guesstimate.  You can kinda see it hiding under there.  Mounted the Holley Hi-Ram to check for clearance issues.   I have always hated the 67-72 dash. It's flat, tall, ugly and boring.   So about 5:30 last night I'm in the shop and Ed(Owner of TCI) comes walking out of his office. I'm sitting on a short stool inside the cab just staring at the dash contemplating things. Ed says "You know, when I was building my Mustang I wish I would have cut the dash out. It would have made my life much easier". That was all I needed to hear. I grabbed a sharpie and started marking it up. Removed the few retaining bolts and fired up the plasma cutter. I left a one inch flange to attach the replacement dash to later.   With the dash out it became very clear to me how the tunnel and firewall should be cut. I knew I wanted to push the engine back, I just didn't know how much.  So I took some measurements and rigged up a floor mounted fixture to use as a guide with the plasma cutter and went to town.   Once you exceed 3-4" of setback things start to get interesting (difficult). However, once you go beyond 3-4" it's not much different to go 10-12" vs. 6". In the position below the engine is back 10" from the factory location.

|

|

|

|

|

|

#154 |

|

Registered User

Join Date: Apr 2001

Location: DALLAS,TX

Posts: 22,066

|

Re: TCI to start new R&D Project with a C10!

Ouch..... Maintenance is going to be a beoch.

__________________

67SWB-B.B.RetroRod 64SWB-Recycle 89CCDually-Driver/Tow Truck 99CCSWB Driver All Fleetsides @rattlecankustoms in IG Building a small, high rpm engine with the perfect bore, stroke and rod ratio is very impressive. It's like a highly skilled Morrocan sword fighter with a Damascus Steel Scimitar..... Cubic inches is like Indiana Jones with a cheap pistol. |

|

|

|

|

|

#155 |

|

Registered User

Join Date: Mar 2011

Location: SoCal

Posts: 151

|

Re: TCI to start new R&D Project with a C10!

|

|

|

|

|

|

#156 |

|

Registered User

Join Date: Mar 2005

Location: 10-Uh-See

Posts: 5,609

|

Re: TCI to start new R&D Project with a C10!

__________________

|

|

|

|

|

|

#157 |

|

Registered User

Join Date: Oct 2013

Location: Alabama

Posts: 1,234

|

Re: TCI to start new R&D Project with a C10!

|

|

|

|

|

|

#158 |

|

Registered User

Join Date: May 2007

Location: Deale Md

Posts: 4,663

|

Re: TCI to start new R&D Project with a C10!

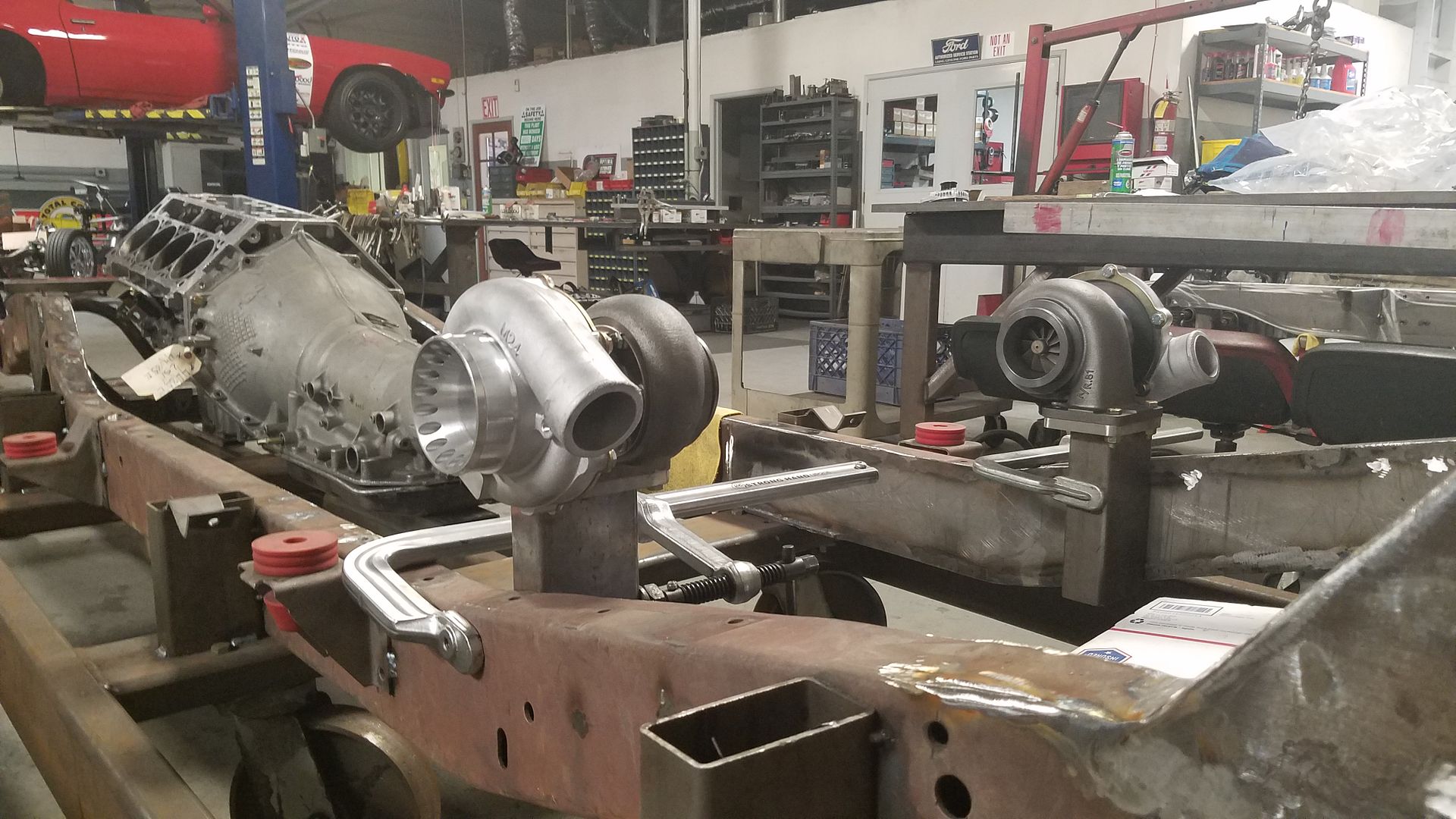

With the engine set back there's plenty of room for the twins out front.

__________________

James 63 GMC V6 4speed carryall 65 chevy swb bbw V8 auto 68 K20 327/4 speed, buddy buckets 2002 GMC CC Dually Duramax 64 GMC lwb 3/4 V6 4speed SOLD 66 GMC swb bbw buddy buckets SOLD IG duallyjams The only thing that stays the same is constant change! |

|

|

|

|

|

#159 | |

|

Registered User

Join Date: Mar 2011

Location: SoCal

Posts: 151

|

Re: TCI to start new R&D Project with a C10!

Quote:

We have a few different sets of headers sitting around the shop we use for mock up. Of all the ones I tried our own off the shelf headers fit the best. Mainly because the rear cylinder primaries go forward slightly before going down. This actually allowed me to move the engine back another 2.5"(12.5" total) with relative ease. I had to raise the engine in order to keep the pans(engine & tranny) above the bottom of the frame anyway. It had to go up over an inch(too much) in order to keep the transmission tabs off the tunnel. Now I've got clearance issues with the intake manifold. Next week I'll trim the tunnel a little more where the tranny tabs are interfering so I can bring the engine down roughly 1/2". This may or may not be enough to clear the intake manifold again. Needless to say if the engine stays this far back I will have a constant foot warmer.

|

|

|

|

|

|

|

#160 |

|

Registered User

Join Date: Jul 2009

Location: San Jose Ca

Posts: 2,871

|

Re: TCI to start new R&D Project with a C10!

I really like the idea of the super far set back. I have mine set back about 3 inches and want to do more but I'm concerned about doing any engine work. I guess a removable hump would solve that. I don't think my engine hoist would even let me get that far back either....

Great project. Looks awesome and cant wait to see how it turns out.

__________________

David Used parts build: http://67-72chevytrucks.com/vboard/s...d.php?t=638991 My brother's Nova: http://www.67-72chevytrucks.com/vboa...d.php?t=727985 Rear suspension rework: http://www.67-72chevytrucks.com/vboa...d.php?t=750557 Instagram: myfabguy |

|

|

|

|

|

#161 |

|

Registered User

Join Date: Mar 2007

Location: Farmington, MN

Posts: 928

|

Re: TCI to start new R&D Project with a C10!

Getting to the engine would be like a van if you use a removable dog house or engine cover. The engine could be offset to the passenger side slightly if you needed a little more leg room.

__________________

I can still count my vehicles on two... wait three hands. |

|

|

|

|

|

#162 |

|

Registered User

Join Date: Mar 2011

Location: SoCal

Posts: 151

|

Re: TCI to start new R&D Project with a C10!

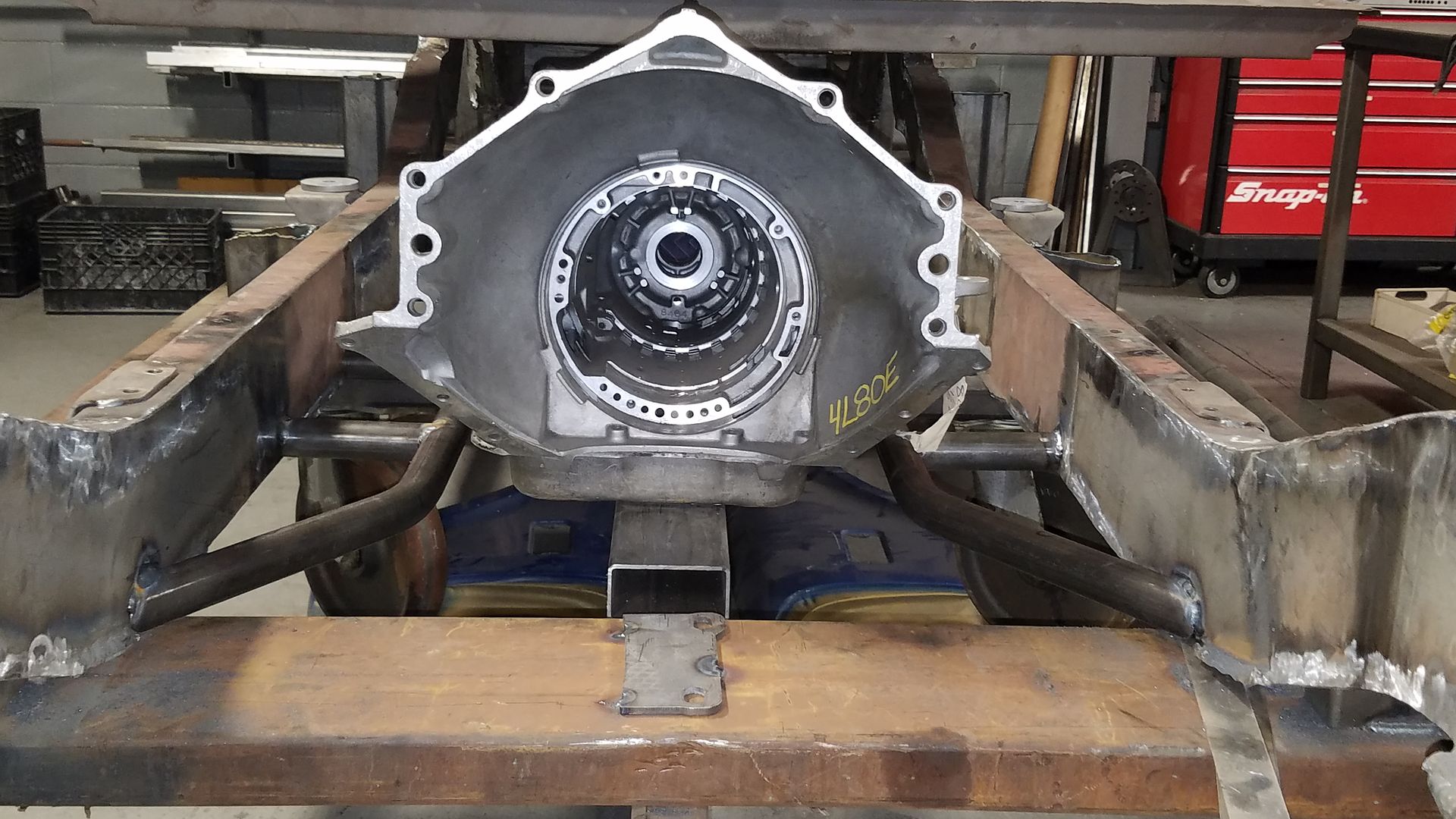

Haven't made much progress lately. Ed and I have been discussing the chassis center section and engine placement at length. There is no physical way to lower the engine in place so we've decided to build a removable lower section of the chassis. It will have 6 attachment points and allow the body/chassis to be lowered over the top of it. I've built this over and over in my head so many times that I get disappointed when I walk into R&D and see that it isn't physically built yet. I should start on it today though.

Much like the engine placement, cab placement is still up in the air. I had read and spoke to a few C10 builders that if you body drop .75" the bottom of the pinch weld will be dead even with the bottom of the frame. That's not the case on this truck. I am currently using our Camaro 3/8" spacers(which are roughly.75" less than the stock rubber mounts) between the cab and frame mounts and the pinch weld is still well below the bottom of the frame. On top of that the rear of the cab is lower than the front, using the frame as reference. This kind of works to my advantage though. I had kinda wanted to tilt/rake the whole body down a degree or two in the front. My plan is to make the bottom of the cab parallel to the bottom of the frame. All of that means that the core support bushings will also need to be modified to assume the new angle. This pic is with roughly 1" less thickness.  I was at a stand still with cab placement because I wanted the pinch weld rolled up flat. I'm an OCD photog so i've seen way to many good looking trucks be ruined by the pinch weld.  -J Last edited by slow4dr; 10-26-2017 at 02:09 PM. |

|

|

|

|

|

#163 |

|

Registered User

Join Date: Mar 2011

Location: SoCal

Posts: 151

|

Re: TCI to start new R&D Project with a C10!

|

|

|

|

|

|

#164 |

|

Registered User

Join Date: Mar 2011

Location: SoCal

Posts: 151

|

Re: TCI to start new R&D Project with a C10!

SEMA, Pleasanton & Scottsdale, 3 weekends in a row working out of town has slowed progress on the C10.

We needed a little room under the cab for intercooler piping.  Still need to roll the edge to add some strength.  Started working on the chromoly center section. Form fitted around the tranny on the bottom side. The two middle tubes aren't mounted yet. There will be a couple cross braces added for the tranny mount & driveshaft loop. *NOTE* The relationship between the front of the bell housing and the cab mount.    The Torque Arm will end up filling out this space so I needed to devise a way to gain clearance. It took some thought to get the angles right but the bend came out perfect (Even though chromoly deflects so much after being bent).

Last edited by slow4dr; 11-20-2017 at 01:32 PM. |

|

|

|

|

|

#165 |

|

Registered User

Join Date: Mar 2011

Location: SoCal

Posts: 151

|

Re: TCI to start new R&D Project with a C10!

Still plugging away on the center section. Built the main tranny hoop and tied it in with some downbars. It is just tacked in place at this time. I still need to throw the cab back on to confirm placement. It'll make sense why the tubes are on top of the frame once the cab is back on.

I still need to make a couple tabs to close out the round tube on top of the frame.  The rear tube placement must be 21" behind the front one to fit properly. I plan to tie the driveshaft loop, tranny mount and Torque Arm mount all together in that area.

|

|

|

|

|

|

#166 |

|

Registered User

Join Date: Jul 2009

Location: San Jose Ca

Posts: 2,871

|

Re: TCI to start new R&D Project with a C10!

Looks great. I plan on doing something similar with the tubes. Have you seen the mounts to tie the chassis to the back of the heads?

__________________

David Used parts build: http://67-72chevytrucks.com/vboard/s...d.php?t=638991 My brother's Nova: http://www.67-72chevytrucks.com/vboa...d.php?t=727985 Rear suspension rework: http://www.67-72chevytrucks.com/vboa...d.php?t=750557 Instagram: myfabguy |

|

|

|

|

|

#167 |

|

Registered User

Join Date: Mar 2011

Location: SoCal

Posts: 151

|

Re: TCI to start new R&D Project with a C10!

|

|

|

|

|

|

#168 |

|

Registered User

Join Date: Jul 2009

Location: San Jose Ca

Posts: 2,871

|

Re: TCI to start new R&D Project with a C10!

__________________

David Used parts build: http://67-72chevytrucks.com/vboard/s...d.php?t=638991 My brother's Nova: http://www.67-72chevytrucks.com/vboa...d.php?t=727985 Rear suspension rework: http://www.67-72chevytrucks.com/vboa...d.php?t=750557 Instagram: myfabguy |

|

|

|

|

|

#169 | |

|

Registered User

Join Date: Mar 2011

Location: SoCal

Posts: 151

|

Re: TCI to start new R&D Project with a C10!

Quote:

We had our friends at California Rebuilt Exchange build us a quick ratio manual rack. Yes, that's right, a manual rack with what will likely be 315 or 335 tires on the steering axle. I better start eating all the spinach.  In all seriousness though. We are going to begin testing the feasability of running EPAS with our suspension. I figure that if it can handle this type of load & abuse then pretty much every other application will be just fine.

|

|

|

|

|

|

|

#170 |

|

Registered User

Join Date: Jul 2009

Location: San Jose Ca

Posts: 2,871

|

Re: TCI to start new R&D Project with a C10!

I think the original purpose of the mounts were for that. I don't have the engineering background to figure it out but I have always wondered how much chassis stiffness is lost by only adding tube and triangulating the back half of the chassis. I'd assume that by adding more to the front it would deflect much less (like when you add the forward bars in a cage).

__________________

David Used parts build: http://67-72chevytrucks.com/vboard/s...d.php?t=638991 My brother's Nova: http://www.67-72chevytrucks.com/vboa...d.php?t=727985 Rear suspension rework: http://www.67-72chevytrucks.com/vboa...d.php?t=750557 Instagram: myfabguy |

|

|

|

|

|

#171 |

|

Registered User

Join Date: Mar 2011

Location: SoCal

Posts: 151

|

Re: TCI to start new R&D Project with a C10!

I had hinted at why the chassis cross bars were mounted above the frame rails earlier. The cab has two raised areas in the floor that the tubes line up with. This allows maximum exhaust clearance through the center section. Might even try to incorporate additional cab mounts and seat mounts into them. If you've been paying attention you've seen a couple different pics of engine set back options. I think "The Sweet Spot" has been found, see pic for measurement.

Getting the cab and bed perfectly aligned has proven to be next to impossible without bedsides. Started cutting up these brand new bed sides so we can raise the bed floor.  It's kinda hard to see what's going on here. This is the piece that was cut and removed from the bed side. It is now mounted into position on the bed floor. The driver side will be the same except where the gas filler is currently mounted.

|

|

|

|

|

|

#172 |

|

Registered User

Join Date: Mar 2011

Location: SoCal

Posts: 151

|

Re: TCI to start new R&D Project with a C10!

Slowly making progress on mounting the bed sides. I cut a fairly big strip out first and then just trimmed little by little in order not to cut too much. It is a long process but the fitment was perfect. The goal was to keep the factory internal bed body lines for looks and strength. Just kinda sandwiched them closer together. The inner panel will require a little more work once I get the main structure together.

|

|

|

|

|

|

#173 |

|

I'm just glad to be here!

Join Date: Jan 2008

Location: Longview, TX

Posts: 4,788

|

Re: TCI to start new R&D Project with a C10!

Nice.

__________________

Karl  1965 Chevy Stepside(Grandpa's Old Blue) and (July 2015 Shop Build!)(2020, the Saga Continues) http://67-72chevytrucks.com/vboard/s...d.php?t=372424 The LST Challenge: http://67-72chevytrucks.com/vboard/s...=1#post7812257 Korbin's 1st Square: "Sunburn" http://67-72chevytrucks.com/vboard/s...d.php?t=418618 1985 GMC Sierra: "White Trash", Korbin's 2nd now... http://67-72chevytrucks.com/vboard/s...d.php?t=632305 Henry - 1984 Chevrolet, Owen's 1st Square |

|

|

|

|

|

#174 |

|

Registered User

Join Date: Mar 2011

Location: SoCal

Posts: 151

|

Re: TCI to start new R&D Project with a C10!

|

|

|

|

|

|

#175 |

|

Registered User

Join Date: Mar 2011

Location: SoCal

Posts: 151

|

Re: TCI to start new R&D Project with a C10!

Been trying to get the bed back to a solid piece for safe removal. Made some closeout panels for the outer structure and fitted them up this morning.

Made a cardboard template (oversized of course so I could trim to fit)  .050" panel cut and ready  So I kinda skipped a picture/step here. I cut a few slits in the lip and rolled the edge before laying the new panel in place. The top is butt welded, the bottom is laid inside of the lip.  This should at least hold the structure in place so I can remove the bed, disassemble and fully weld on a bench (comfortably). |

|

|

|

|

| Bookmarks |

|

|