|

|

|

#1851 | |

|

Senior Member

Join Date: Jul 2010

Location: Dandridge, Tn. USA

Posts: 2,226

|

Re: Make it handle

Quote:

To start with, you need to be able to set the vehicle (or at least the rear suspension), at Ride Height. So, here is what I would do. 1) put the truck or chassis up on some jack stands, as I get older, I realize the value of not bending over and/or laying on the floor. Get it nice and level all the way around. 2) With the rear suspension mocked up, make up a spring block (coil spring or bag) or a set-up bar (coil over) that holds the suspension at Ride Height. This would be appx half of the shock travel for a coil-over, for a coil spring or bag, give yourself 3" to 4" to the frame for up travel. (you results may vary, depending on chassis mods, this is for you to decide) But, try to get it close. Kugal Komponents has cool adjustable set-up bars for builders. Check them out. 3) Measure the angle of the crankshaft. Yes, you have to put the motor and trans in. Or, at least a shell of each. The oil pan rail is on the crank CL. Also, you can use the balancer face, as the are 90 degrees to one another. 4) As a starting point, set the pinion at the same angle as the crack. Not 'pointed at it', but the same angle (see pict) Using the face of the pinion yoke is easiest. 5) Now, make adjustments to match the type of suspension you have. Leaf Springs - push the front of the pinion down 2* to 3*. Coils or Bags on Trailing Arms - Push the front of the pinion down 1 1/2* to 2*. 4-Bar with poly bushings - push the front of the pinion down 1* to 1 1/2* 4-Bar with Delron or Heims - push the front of the pinion down 1/2* to 1* OK, that's how I do it. I'm sure others have different ways, but this method had worked great for No Limit for 30+ years. Can't argue with success.

__________________

GoodGuys 2012 Pro-Truck Champion  2012 Truckin' Throwdown Champion GoodGuys 2011 National Champion  2011 Truckin' Throwdown Champion GoodGuys 2010 National Champion  Proud to put our products up against all others! |

|

|

|

|

|

|

#1852 | |

|

Senior Member

Join Date: Jul 2010

Location: Dandridge, Tn. USA

Posts: 2,226

|

Re: Make it handle

Quote:

__________________

GoodGuys 2012 Pro-Truck Champion  2012 Truckin' Throwdown Champion GoodGuys 2011 National Champion  2011 Truckin' Throwdown Champion GoodGuys 2010 National Champion  Proud to put our products up against all others! |

|

|

|

|

|

|

#1853 |

|

Registered User

Join Date: May 2011

Location: Missoula, MT

Posts: 934

|

Re: Make it handle

Rob,

I am currently moving my lower control arms forward 3/4" on my 69 GMC by re-indexing the the holes on the cross shaft and was wondering how that is going to effect my factory sway bar? Should I be moving my upper sway bar mounts forward 3/4" for clearance or efficiency, or should I not worry about it? Also, thank you for not abandoning this page and continuing to answer questions!

__________________

69 GMC C10 build thread- http://67-72chevytrucks.com/vboard/s...d.php?t=501676 03 Silverado build thread-http://67-72chevytrucks.com/vboard/s...d.php?t=591582 |

|

|

|

|

|

#1854 | |

|

Registered User

Join Date: Jun 2011

Location: Spokane, WA

Posts: 2,372

|

Re: Make it handle

Quote:

__________________

'77 K30 3+3 - "The Crummy" http://67-72chevytrucks.com/vboard/s...d.php?t=640134 '67 C10 L/SWB - Soon to be daily driver! http://67-72chevytrucks.com/vboard/s...d.php?t=471776

|

|

|

|

|

|

|

#1855 |

|

Registered User

Join Date: Jan 2011

Location: Mount Airy, NC

Posts: 132

|

Re: Make it handle

Does anyone know if welding ends on a sway bar will cause any strength problems?

__________________

Jack Byrd '70 Chev Custom SWB(new to me), 307CID(added Weiand Stealth, headers and Edelbrock Performer carb, up to 17 MPG now), 700R4 '76 Airstream Argosy MH(want a longer one), 454CID, TH400 |

|

|

|

|

|

#1856 |

|

Registered User

Join Date: Jul 2009

Location: San Jose Ca

Posts: 2,871

|

Re: Make it handle

In general you dont want to weld on springs or anything heat treated.

__________________

David Used parts build: http://67-72chevytrucks.com/vboard/s...d.php?t=638991 My brother's Nova: http://www.67-72chevytrucks.com/vboa...d.php?t=727985 Rear suspension rework: http://www.67-72chevytrucks.com/vboa...d.php?t=750557 Instagram: myfabguy |

|

|

|

|

|

#1857 |

|

Registered User

Join Date: Jul 2009

Location: San Jose Ca

Posts: 2,871

|

Re: Make it handle

Rob can you talk about the addition of tube connecting the body to the frame in order to stiffen the chassis up?

I got these pics off the protouring forum:    This guy was making a cage in which he can remove the body (obviously) but would it be beneficial for us who arent running a cage to add tube in a similar fashion using 6x6 1/8'' plates to distribute the weight on the body? I dont know if I want to do a cage but I like the idea this guy had.

__________________

David Used parts build: http://67-72chevytrucks.com/vboard/s...d.php?t=638991 My brother's Nova: http://www.67-72chevytrucks.com/vboa...d.php?t=727985 Rear suspension rework: http://www.67-72chevytrucks.com/vboa...d.php?t=750557 Instagram: myfabguy |

|

|

|

|

|

#1858 |

|

Project underway - finally.

Join Date: Feb 2007

Location: Greenville, SC

Posts: 493

|

Re: Make it handle

What exists to adjust bumpsteer following a relocated ball joint height?

__________________

1972 GMC Pre-resto... awaiting allocated funding. |

|

|

|

|

|

#1859 |

|

Registered User

Join Date: Mar 2013

Location: Marquette michigan

Posts: 828

|

Re: Make it handle

Good question. If your upper control arm length was correct before changing ball joint height you would have to shorten/lengthen the upper control arm length to compensate for the change.

I have NOT purchased any aftermarket front end system yet because very few address bumpsteer correctly when designing a new system. All you have to look at is if the upper control arm can be lengthened/shortened within the "A" arm itself, (this is based on the fact that the lower control arm is a fixed length). Slotted upper arm mounts, eccentric cams, shims, affect bumpsteer. As i think about this a little more the spindle contains the 3 pivot points, upper and lower ball joints and the outer tie rod end so if the relocated ball joint height is part of the spindle and is on the same plane as stock you should see no change If you had an adjustable upper "A" arm. If not, you would have to move the upper arm in/out to correct for the ball joint change to maintain your desired alignment angles and would impact the bumpsteer amount. |

|

|

|

|

|

#1860 |

|

Project underway - finally.

Join Date: Feb 2007

Location: Greenville, SC

Posts: 493

|

Re: Make it handle

Why not move the steering idler and box around and leave the control arms alone?

__________________

1972 GMC Pre-resto... awaiting allocated funding. |

|

|

|

|

|

#1861 |

|

Registered User

Join Date: Mar 2013

Location: Lakeside, Ca.

Posts: 320

|

Re: Make it handle

Here are my bumpsteer adjusters i built. They are stainless steel, machined taper to match c10 spindles, with a 5/8-18 thread to use a 5/8 heim.

__________________

Project Roxy... Shes Bad, Low, and Blown... http://67-72chevytrucks.com/vboard/s...d.php?t=673333 |

|

|

|

|

|

#1862 |

|

Project underway - finally.

Join Date: Feb 2007

Location: Greenville, SC

Posts: 493

|

Re: Make it handle

How do you use those? Not trying to be ignorant, but I can't figure out what you're doing there.

__________________

1972 GMC Pre-resto... awaiting allocated funding. |

|

|

|

|

|

#1863 |

|

Registered User

Join Date: Jul 2009

Location: San Jose Ca

Posts: 2,871

|

Re: Make it handle

I am assuming he bolts the tapered side into the spindle and uses a heim joint instead of a tie rod end on the other side. It would allow the height of the tie rod to be adjustable.

__________________

David Used parts build: http://67-72chevytrucks.com/vboard/s...d.php?t=638991 My brother's Nova: http://www.67-72chevytrucks.com/vboa...d.php?t=727985 Rear suspension rework: http://www.67-72chevytrucks.com/vboa...d.php?t=750557 Instagram: myfabguy |

|

|

|

|

|

#1864 |

|

Project underway - finally.

Join Date: Feb 2007

Location: Greenville, SC

Posts: 493

|

Re: Make it handle

Ahh, I see. So are we comfortable using a heim joint rather than a ball joint on steering gear for the street? I thought that was rather difficult and expensive to do properly.

__________________

1972 GMC Pre-resto... awaiting allocated funding. |

|

|

|

|

|

#1865 |

|

Registered User

Join Date: Apr 2001

Location: DALLAS,TX

Posts: 22,066

|

Re: Make it handle

Many aftermarket R&P set-ups are connected using Heim joints. Not as good or durable (from a maintenance perspective) as a better sealed Tie-Rod end but definitely usable.

__________________

67SWB-B.B.RetroRod 64SWB-Recycle 89CCDually-Driver/Tow Truck 99CCSWB Driver All Fleetsides @rattlecankustoms in IG Building a small, high rpm engine with the perfect bore, stroke and rod ratio is very impressive. It's like a highly skilled Morrocan sword fighter with a Damascus Steel Scimitar..... Cubic inches is like Indiana Jones with a cheap pistol. |

|

|

|

|

|

#1866 | |

|

Registered User

Join Date: Nov 2010

Location: Los Angeles, CA

Posts: 1,018

|

Re: Make it handle

Quote:

I am all about stainless fasteners and parts, for all kinds of things, just make sure you take into consideration the requirements of the piece. Not saying you didn't, just don't want to see someone go off a cliff for pretty. |

|

|

|

|

|

|

#1867 |

|

Registered User

Join Date: Mar 2013

Location: Lakeside, Ca.

Posts: 320

|

Re: Make it handle

I'm using a 304 stainless, but plan on adding a double shear plate to the top that bolts to the spindle.

__________________

Project Roxy... Shes Bad, Low, and Blown... http://67-72chevytrucks.com/vboard/s...d.php?t=673333 |

|

|

|

|

|

#1868 |

|

Registered User

Join Date: Nov 2010

Location: Los Angeles, CA

Posts: 1,018

|

Re: Make it handle

Just checking, blown small block, manual trans and California curves. If you got that speed bug here, you better trust your machine.

|

|

|

|

|

|

#1869 |

|

Registered User

Join Date: Mar 2013

Location: Lakeside, Ca.

Posts: 320

|

Re: Make it handle

Thanks for looking out.. shouldn't be any sheer issues.. definitely working on over building the chassis..

__________________

Project Roxy... Shes Bad, Low, and Blown... http://67-72chevytrucks.com/vboard/s...d.php?t=673333 |

|

|

|

|

|

#1870 |

|

Senior Member

Join Date: Jul 2010

Location: Dandridge, Tn. USA

Posts: 2,226

|

Re: Make it handle

Good topic. Tall or raised ball joints will have little effect on bump steer, and are usually used to adjust the roll center and/or quicken the rate of camber gain. Adding caster, and thus tipping the spindle back, and raising the outer tie rod end pivot center, can have big effects on bump steer. These types of studs are common, and can be found at Speedway, How Racing, Coleman Racing, and other circle track suppliers. Google 'bump steer kit' and you can find a bunch. Good bumpsteer curves come from the initial design, and can be tuned (slight bump out in compression is best) bad bump curves are a design fault, and usually cannot be tuned out with studs/spacers. Keep pushing the design.

__________________

GoodGuys 2012 Pro-Truck Champion  2012 Truckin' Throwdown Champion GoodGuys 2011 National Champion  2011 Truckin' Throwdown Champion GoodGuys 2010 National Champion  Proud to put our products up against all others! |

|

|

|

|

|

#1871 |

|

Registered User

Join Date: Mar 2013

Location: Lakeside, Ca.

Posts: 320

|

Re: Make it handle

Thanks for the good words Rob.

__________________

Project Roxy... Shes Bad, Low, and Blown... http://67-72chevytrucks.com/vboard/s...d.php?t=673333 |

|

|

|

|

|

#1872 |

|

Registered User

Join Date: Nov 2013

Location: colville washington

Posts: 20

|

Re: Make it handle

This is a great thread and thanks Rob for all the info.

I'm already starting with a disadvantage because my truck has a BB in it so the front end is heavy but still would like to make the truck handle its best until I get around to an LS swap. A couple quick questions I have are based on wheel and tire width. This is what I was thinking: 20" wheels,10"wide front and 12 on the back 295 or 305 (28" tall) front if they fit and 15" wide (29" tall) MT on the back 5/7 drop - 1.5" sectioned CM with 2.5 spindles and 1" drop spring with coilovers (outside frame rails) and blocks in back Can too much rubber a bad thing? Wider in the back or matching width as the front? Better to center the offset on the front rim and narrow control arm or have regular length control arms with more offset? In the back is it worth the money to center the offset and narrow the rear end? Do you see any issues with what I have planned? Thanks in advance and sorry if something like this has been covered! |

|

|

|

|

|

#1873 |

|

Collector of Projects

Join Date: Apr 2003

Location: Las Vegas

Posts: 3,106

|

Re: Make it handle

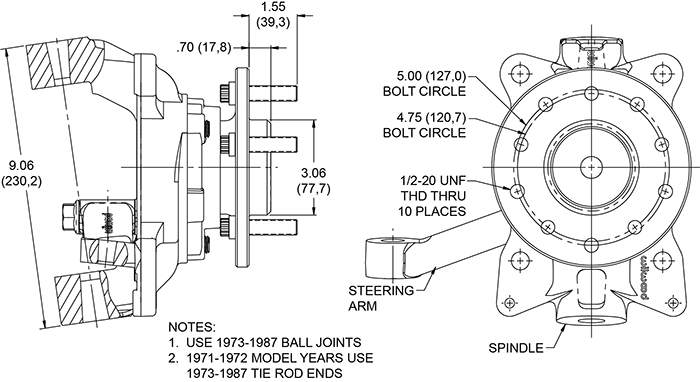

Hey Rob, have you seen the Wilwood ProSpindle kit? It has a modular design with a removable steering arm, sealed bearing for slip on rotors and a 2.5" built in drop.

http://www.wilwood.com/PDF/Flyers/fl427.pdf ..................... http://www.wilwood.com/PDF/DataSheets/ds1194.pdf

|

|

|

|

|

|

#1874 |

|

Registered User

Join Date: Dec 2002

Location: Cactus Patch So. Az

Posts: 4,749

|

Re: Make it handle

Complete spindle and hub and only 750 more to my build!

__________________

53 TuTone Extended Cab 350 4-Spd 3:08 (SOLD) 53 Chevy Moldy pearl green ZZ-4 4L60E 9" 3:25 55 GMC 1st Black Mll (ZZ4) ZZ6 TKO 600 5 sp 3:73 62 Solidaxle Corvette Roman Red (327 340hp 4spd 3:36) C4 & C5 suspension tube chassis LS 3 4L70E 65 Corvette Coupe 327 350hp 4spd 4:11 78 Black Silverado SWB (350/350) 5.3 & 4L60E 3:42 2000 S-Type 3.0 (wife cruiser) 2003 GMC SCSB 5.3 4L60E 3:42 |

|

|

|

|

|

#1875 |

|

Registered User

Join Date: May 2016

Location: Goodyear, AZ

Posts: 11

|

Re: Make it handle

Question regarding bump steer and my alignment guy. Specifics on my truck are below. Having the truck aligned to -0.5* camber, 1/8" toe, and as much positive caster as possible. Hoping for 7-9* caster total.

Am I going to have a big bump steer issue?!?! If so, what center link do I need to buy to fix/improve it? Basically the alignment guy said that anything more than 3* caster would cause huge bump steer and he would not align it, despite the directions stating specs from Ridetech. I tried to explain that the arms take this into account, but he still refused. Needless to say I got on the phone with Ridetech the next day, and they again stated that the arms have taken this into account. Looking through this thread, it seems that the lowered truck with high caster would actually help improve bump steer, but I may have read that wrong....with the 5/8" too high ITR mounting point on the center link....or conversely 5/8" too low on the OTR mount. By adding caster, we are actually improving this....right? '71 c10 LWB Ridetech Shockwave HQ bagovers & StongArms 1.25" MuscleBar new ITRs, OTRs, pitman, and idler arms stock center link billet adjuster sleeves Belltech 2.5" drop spindles AGR steering box 29.5" height at the fenders, on the 265/50/R20 Thanks! ~Ryan |

|

|

|

|

| Bookmarks |

|

|