|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Senior Member

Join Date: May 2004

Location: johnstown, NY

Posts: 2,393

|

how to manifold valves

Can anybody explain how to do this with 8 valves. I like the idea of how these setups are clean looking, but never read how to do it.

|

|

|

|

|

|

#2 |

|

Registered User

Join Date: May 2005

Location: Beaverton, OR

Posts: 3,728

|

Re: how to manifold valves

It depends on where you're mounting them. A common practice is to use 4 ports on the side of the tank.

Run a brass nipple from the tank to the fill valve. Brass nipple from the fill valve to a Tee fitting (I used the Suicide Doors T with gauge fitting), or you could use a street tee and connect it to the output of the fill valve without a nipple. Nipple on the bottom to the dump valve. Hose fitting out of the Tee to the bag. Repeat for each bag. That is if you are using standard valves. There are "valve manifolds" that are valves integrated into a solid piece that has inputs/outputs on it. Last edited by jimmydean; 01-16-2007 at 01:34 AM. |

|

|

|

|

|

#3 |

|

Senior Member

Join Date: May 2004

Location: johnstown, NY

Posts: 2,393

|

Re: how to manifold valves

Thats what I was talking about. Can that be done with standard valves or does a solid block of aluminum need to be machined?

|

|

|

|

|

|

#4 |

|

Registered User

Join Date: May 2005

Location: Beaverton, OR

Posts: 3,728

|

Re: how to manifold valves

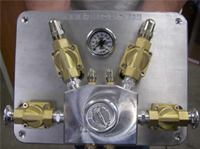

You want something like this? Or do you want to run standard valves?

<edit> they come like this for industrial applications. You can build a solid setup for standard valves using brass too. Just depends on how much work you want to do. Last edited by jimmydean; 01-16-2007 at 02:06 AM. |

|

|

|

|

|

#5 |

|

Senior Member

Join Date: May 2004

Location: johnstown, NY

Posts: 2,393

|

Re: how to manifold valves

Well, yea, that's exactly what I want but don't have the 750 to spend on it. I was wondering if you can set something up like that with standard valves.

|

|

|

|

|

|

#6 |

|

Registered User

Join Date: May 2005

Location: Beaverton, OR

Posts: 3,728

|

Re: how to manifold valves

Here is how my system is laid out. Each valve pair uses a straight fitting to the fill valve, a nipple to the tee, nipple to the dump valve, and a straight fitting to the bag. I use a u bolt to mount the valve setup to the inside of the frame rail. Mine is a little different that the others because I only had a single output on the tank and I didn't want to try and hang 8 1/2" valves off a single port.

I like the way it turned out because the valves are protected and it leave a lot of room. |

|

|

|

|

|

#7 |

|

Registered User

Join Date: May 2005

Location: Beaverton, OR

Posts: 3,728

|

Re: how to manifold valves

Also, considering the manifold is all your valves an a lot of fittings, figure 8 1/2" valves are $350, then the fittings are another $100. So building something saves you about $300, but then you have to figure how you want it all laid out. With the manifold, all you run is lines.

Not sure how you set up gauges, I think it has ports for that too. |

|

|

|

|

|

#8 |

|

Epoxy Primer Friendly

Join Date: Feb 2004

Location: South of Houston TEXXXAS

Posts: 680

|

Re: how to manifold valves

contact BILLETIN thats who made my manifold out of aluminum. It cleans everything up especially if you are only running nitrogen bottles and no air tanks.

Last edited by camaro__thunder; 01-16-2007 at 04:38 AM. |

|

|

|

|

|

#9 | |

|

Senior Member

Join Date: May 2004

Location: johnstown, NY

Posts: 2,393

|

Re: how to manifold valves

Quote:

Question for Jimmydean. Shouldnt the water trap be installed between the compressor and the tank? I thought the main purpose of the trap is to keep water out of the tank, and in return, out of your valves? |

|

|

|

|

|

|

#10 |

|

Registered User

Join Date: May 2005

Location: Beaverton, OR

Posts: 3,728

|

Re: how to manifold valves

The diagram is a little off. The trap is first, then the check valve.

The water trap is best AFTER the tank because condensation collects in the tank from the compressed air and temp changes. 80% of the water in an air system is created in the tank. So you COULD put a trap between the compressor and the tank, but you will still have a lot of water in your system. The goal is to protect your valves, not your tank. |

|

|

|

|

|

#11 | |

|

Outlandish Trends - FL

Join Date: Jul 2005

Location: Orlando

Posts: 1,396

|

Re: how to manifold valves

Quote:

__________________

-Bret 67 short-fleet sold! |

|

|

|

|

|

|

#12 |

|

Senior Member

Join Date: May 2004

Location: johnstown, NY

Posts: 2,393

|

Re: how to manifold valves

I was hoping we would get more opinions on this topic. I am still up in the air myself. An argument for putting the trap after the tank is that the compressor is producing warm air that is going to condense anyway once it goes into a lower temp tank. An argument for the trap before the tank is that the compressor is what is taking the air which has moisture in it and putting that into the tank.

I really don't know what i'm talking about, LOL! |

|

|

|

|

|

#13 | |

|

Registered User

Join Date: May 2005

Location: Beaverton, OR

Posts: 3,728

|

Re: how to manifold valves

Quote:

You will get more water build up in the tank from the compression of air than you will from the air being drawn in to the compressor. It is a good idea if you have a lot of humidity to have a water trap before the tank as well. But the fact remains that your tank will have a lot of water in it from the air being compressed. If you don't have a trap between your tank and valves, you will soon have a lot of water in your valves, then in your bags (would that make them water bags?). If you look at any shop compressor for paint, you will see the water trap between the tank and the gun to keep water out of the paint. Same idea is applied here. |

|

|

|

|

|

|

#14 |

|

Senior Member

Join Date: Mar 2006

Location: modesto CA

Posts: 239

|

Re: how to manifold valves

this in one side the air from tank goes in middle then its up valves front and rear then lines out to bags then out valves i have one of theses on each side of the frame

__________________

http://www.cardomain.com/ride/2461088 |

|

|

|

|

|

#15 |

|

Registered User

Join Date: May 2005

Location: Beaverton, OR

Posts: 3,728

|

Re: how to manifold valves

pharcyde05, so that's a side? If I understand how that's laid out, you have fill/dump on the left and fill/dump on the right and the 90 goes to the bag, correct?

Where did you mount these? I was going to use pipe for mine, but it took up too much space. I had a ton of leakage problems with the drivers rear and that was using machined brass fittings. Did you have any leakage issues with the steel to brass connections? |

|

|

|

|

|

#16 |

|

Registered User

Join Date: Oct 2006

Location: Glendale, AZ

Posts: 41

|

Re: how to manifold valves

67Fleet and jimmydean:

You guys are both correct in a sense. 67Fleet, you obviously have a valid point that if you live in a humid environment, you will get more water droplets as the air is compressed, and thus need the trap before the tank to remove the water/vapor from the air. jimmydean is also correct in stating that you will get water in your tank as the air cools from being compressed, so a trap after the tank is also good. Most of the valves used in todays air ride, save for the crappy valves that AIM sells, are made for industrial applications and are made to flow all sorts of fluids from air, to water, or oil, or many other non-corrosive substances. Most of the water build up in the air tank is at the bottom of the tank, not the middle where most ports are that are used to feed the valves. Putting a trap between the compressor and the tank will remove some water from the air, but not all of it. Water removed includes water formed from the compression of moist air, as well as the condensation formed by the cooling of the air as it moves through the leader hose. With all of that said, I do believe its rather pointless, and an added expense that is unnecessary to use traps after the tank, before the valve. Using one between the tank and compressor is sufficient (and depending on climate, not even needed (I don't use one, never have)), and to have a drain on the tank to remove excess water that forms there is sufficient as well to keep the system operating well so the valves don't get screwed up. 67Fleet, if you believe that all of the water collected in your traps is the extent of the water in your system, you are sorely mistaken. If you've never opened up your tanks to drain them, you will be surprised at the amount of water in there (and rust), especially considering your climate. I'd also like to point out that you can add a product that tractor trailers on the road use in the brake systems called Air Brake Antifreeze. By putting this in your tank (NOT THROUGH THE COMPRESSOR), it will help in eliminating the water in there as well. It is an isopropyl alcohol type substance that will evaporate the water, so to speak. |

|

|

|

|

| Bookmarks |

|

|