|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Junior Member

Join Date: Dec 2006

Location: Newburgh, IN

Posts: 1,247

|

Welding 101 on ol Curt

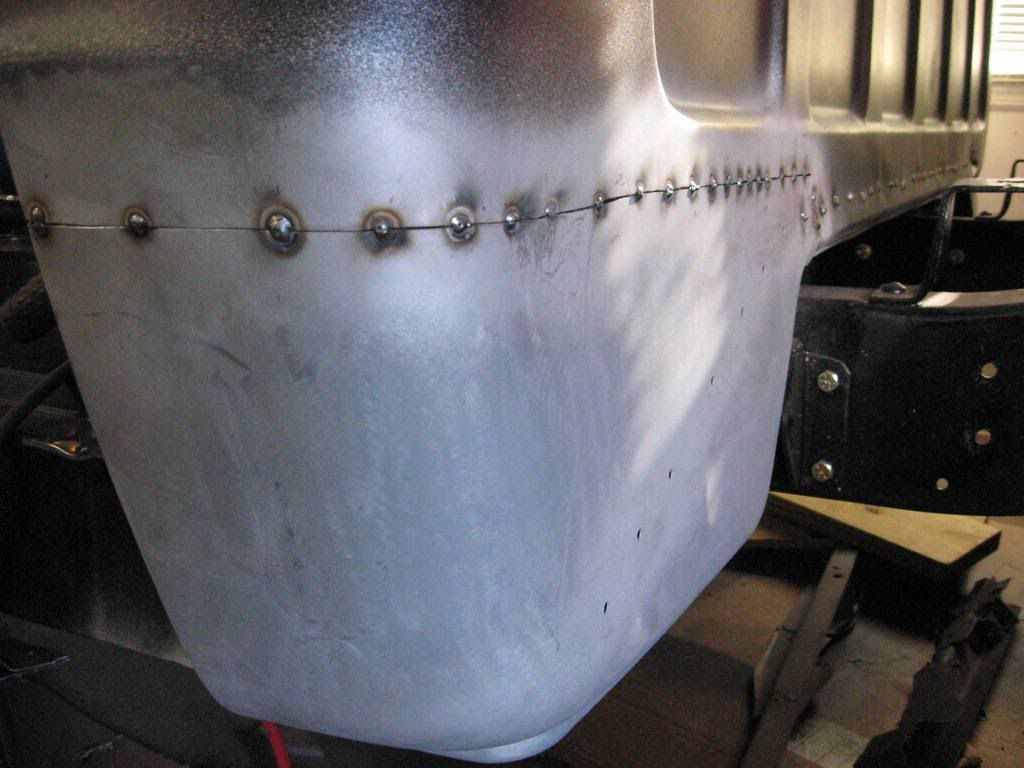

Well, I thought I would try a small repair using the welder. I had a rusted thru/pitted area at the top of the rear wheel cutout on the bedside panel. I thought I would try to cut it out and butt weld another piece in.

I took the first picture and found the batteries were then dead in the camera. That should have been my first clue, but I pushed on! I had the batteries re-charged by the time I finished and was quite proud of my first try. I saw one spot that I thought I could make look a bit better if I put a small tack there to fill it in and grind it back down.......that metal is VERY thin after all that grinding!!! What a dumb a**  I guess I'll have another little spot to cut out and patch.

|

|

|

|

|

|

#2 |

|

1961 crewcab

Join Date: Dec 2007

Location: missoula, mt

Posts: 6,164

|

Re: Welding 101 on ol Curt

try this trick:get a small piece of copper. the weld will not stick to the copper.

clamp it behind your hole, and then slowly fill the hole up with weld. |

|

|

|

|

|

#3 |

|

Registered User

Join Date: Jul 2006

Location: Central PA

Posts: 12,201

|

Re: Welding 101 on ol Curt

copper,brass, wood etc... behind the hole... low heat and quick welds...

__________________

The Garage: 1968 K-10 SWB - "Project Money Pit" 1996 Z-71 - "huntin rig" 1969 C-10 LWB (SOLD) "Project flip that truck or else" 1993 Passport, F@rd 1-ton (SOLD)"Project Cousin Eddie" My Garage Build "The 1,000 footer" |

|

|

|

|

|

#4 |

|

Junior Member

Join Date: Dec 2006

Location: Newburgh, IN

Posts: 1,247

|

Re: Welding 101 on ol Curt

|

|

|

|

|

|

#5 |

|

Registered User

Join Date: Jul 2006

Location: Central PA

Posts: 12,201

|

Re: Welding 101 on ol Curt

build it up from the inside of the hole, don't just pile it up like a big bird turd! I do that often enough!

I did a little welding today too...

__________________

The Garage: 1968 K-10 SWB - "Project Money Pit" 1996 Z-71 - "huntin rig" 1969 C-10 LWB (SOLD) "Project flip that truck or else" 1993 Passport, F@rd 1-ton (SOLD)"Project Cousin Eddie" My Garage Build "The 1,000 footer" |

|

|

|

|

|

#6 |

|

One day...

Join Date: Apr 2008

Location: Tuttle, Ok

Posts: 9,243

|

Re: Welding 101 on ol Curt

And if you do small tacks around the hole you are trying to fill it will work better to. (low heat)

|

|

|

|

|

|

#7 | |

|

One day...

Join Date: Apr 2008

Location: Tuttle, Ok

Posts: 9,243

|

Re: Welding 101 on ol Curt

Quote:

Cool! Are you not going to tack anymore on it? Just curious. |

|

|

|

|

|

|

#8 |

|

Junior Member

Join Date: Dec 2006

Location: Newburgh, IN

Posts: 1,247

|

Re: Welding 101 on ol Curt

This may sound like a really stupid question, but bare in mind I have never welded before this week. Do you guys have the wire actually touching the metal before you trigger the gun, or just close?

|

|

|

|

|

|

#9 |

|

Hey Y'all!!

Join Date: Dec 2007

Location: Bay Minette, Alabama

Posts: 1,755

|

Re: Welding 101 on ol Curt

Looks good for a first attempt at a repair. Just think, a week ago you were still just thinking about being able to do this. It won't be long and you'll be giving welding advice. Congrats!!

On the gun placement, I usually just get it close but I am not sure what the "proper" way is. |

|

|

|

|

|

#10 |

|

Registered User

Join Date: Mar 2007

Location: East Texas

Posts: 429

|

Re: Welding 101 on ol Curt

You want your stick out(amount of wire between the nozzle and the arc)to be 1/2 ",or there about.Clip the wire flush w/nozzle and position your tip 1/2 " from your work ,then angle tip of gun back slightly and press the trigger for a half second only. This works well,assuming wire speed/heat/gas are adjusted propperly. Take your time,make sure any patch material is nice n flush before you tac it.

Last edited by Inverter; 01-03-2009 at 11:17 PM. |

|

|

|

|

|

#11 | |

|

Junior Member

Join Date: Dec 2006

Location: Newburgh, IN

Posts: 1,247

|

Re: Welding 101 on ol Curt

Quote:

|

|

|

|

|

|

|

#12 |

|

Registered User

Join Date: Mar 2007

Location: East Texas

Posts: 429

|

Re: Welding 101 on ol Curt

You are correct.Between the nozzle and your work. Sounds like youve got it.I start around a 1/2" away and,when running a bead,adjust the stick out as needed. For thin stuff you want to make small tacks and move around so as not to warp. What seems to be happening when you weld?

Last edited by Inverter; 01-03-2009 at 11:35 PM. |

|

|

|

|

|

#13 | |

|

Junior Member

Join Date: Dec 2006

Location: Newburgh, IN

Posts: 1,247

|

Re: Welding 101 on ol Curt

Quote:

|

|

|

|

|

|

|

#14 |

|

Junior Member

Join Date: Dec 2006

Location: Newburgh, IN

Posts: 1,247

|

Re: Welding 101 on ol Curt

I have about his much sticking out of the gun when I start...probably 1/4-3/8". It sounds as though I should start with the wire cut off even with the tip but get the tip of the wire within 1/2" of the work.

Hope that makes sense! |

|

|

|

|

|

#15 | |

|

Registered User

Join Date: Mar 2007

Location: East Texas

Posts: 429

|

Re: Welding 101 on ol Curt

Quote:

|

|

|

|

|

|

|

#16 | |

|

Registered User

Join Date: Mar 2007

Location: East Texas

Posts: 429

|

Re: Welding 101 on ol Curt

Quote:

That is what I was saying in my previous post.Clip the wire flush and position the tip over your work. That stick out looks like about 5/8" or more,maybe just the photo. 1/4-3/8 is plenty close. |

|

|

|

|

|

|

#17 |

|

Registered User

Join Date: Jul 2006

Location: Central PA

Posts: 12,201

|

Re: Welding 101 on ol Curt

you could have the wire speed too slow if there is still popping... Is your ground good? metal clean?

When the poer is low I find it harder to get that "sizzle" as well.. and yes, I still have to finish welding my corners, just tacked them in till I know that the door is aligned...

__________________

The Garage: 1968 K-10 SWB - "Project Money Pit" 1996 Z-71 - "huntin rig" 1969 C-10 LWB (SOLD) "Project flip that truck or else" 1993 Passport, F@rd 1-ton (SOLD)"Project Cousin Eddie" My Garage Build "The 1,000 footer" |

|

|

|

|

|

#18 |

|

Registered User

Join Date: Dec 2008

Location: San Diego, CA

Posts: 10

|

Re: Welding 101 on ol Curt

also check the polarity of the welder. The polarity is changed from gas mig welding and innershield flux core wire welding. if they arent connected the correct way it will pop and sputter.

|

|

|

|

|

|

#19 |

|

Registered User

Join Date: Mar 2007

Location: East Texas

Posts: 429

|

Re: Welding 101 on ol Curt

Bam!! forgot about that.I remember going through a half bottle of gas before I figured that one out. Good point.

|

|

|

|

|

|

#20 | |

|

Registered User

Join Date: Dec 2007

Location: Palmer, Alaska

Posts: 13,821

|

Re: Welding 101 on ol Curt

Quote:

__________________

CHEVY ONLY CHEVY ONLY

|

|

|

|

|

|

|

#21 |

|

Registered User

Join Date: Jul 2006

Location: Central PA

Posts: 12,201

|

Re: Welding 101 on ol Curt

and don't run a cheap extension cord either..

just a thought

__________________

The Garage: 1968 K-10 SWB - "Project Money Pit" 1996 Z-71 - "huntin rig" 1969 C-10 LWB (SOLD) "Project flip that truck or else" 1993 Passport, F@rd 1-ton (SOLD)"Project Cousin Eddie" My Garage Build "The 1,000 footer" |

|

|

|

|

|

#22 |

|

Junior Member

Join Date: Dec 2006

Location: Newburgh, IN

Posts: 1,247

|

Re: Welding 101 on ol Curt

Polarity is correct!

|

|

|

|

|

|

#23 |

|

Registered User

Join Date: Jul 2008

Location: Watson LA

Posts: 105

|

Re: Welding 101 on ol Curt

when your grinding, try to stay on your weld till you have it knocked pretty much all the way down and that will keep from thinning out the surrounding material and keep that from happening.

|

|

|

|

|

|

#24 | |

|

Junior Member

Join Date: Dec 2006

Location: Newburgh, IN

Posts: 1,247

|

Re: Welding 101 on ol Curt

Quote:

|

|

|

|

|

|

|

#25 |

|

Registered User

Join Date: Jul 2006

Location: Central PA

Posts: 12,201

|

Re: Welding 101 on ol Curt

ouch...

I like to use the 60 grit flapper discs for grinding... doesn't take too much away on accident... remember that the more angle that you put on your grinder the more metal is eaten away... keep it flat and moving over the entire area so you don't build up a lot of heat...

__________________

The Garage: 1968 K-10 SWB - "Project Money Pit" 1996 Z-71 - "huntin rig" 1969 C-10 LWB (SOLD) "Project flip that truck or else" 1993 Passport, F@rd 1-ton (SOLD)"Project Cousin Eddie" My Garage Build "The 1,000 footer" |

|

|

|

|

| Bookmarks |

|

|