|

Register or Log In To remove these advertisements. |

|

|

|

|||||||

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Registered User

Join Date: Mar 2011

Location: Westchester, NY

Posts: 394

|

Welding up larger holes...

Hello All, just getting in from several hours of welding and grinding, not fun at all. Im working on some trouble spots on the floor of my 58. I noticed that there are additional holes in the floor, presumably from former owners who may have had different seats in it. Judgung from the molestation in the floor (that I just fixed), there may even have been bucket seat in it in the past! Anyway, some of the holes are pretty decent sixed, maybe approaching 1/2" wide, though I think they a bit smaller. THey seem a little too large just to weld up. In these cases do I need to cut out some plugs using sheet metal to close them up? Any ideas would be helpful.

Mark |

|

|

|

|

|

#2 |

|

Registered User

Join Date: Mar 2011

Location: Westchester, NY

Posts: 394

|

Re: Welding up larger holes...

maybe use a copper spoon underneath and just weld away?

|

|

|

|

|

|

#3 |

|

Registered User

Join Date: Mar 2012

Location: Lakes Region NH

Posts: 3,205

|

Re: Welding up larger holes...

I'd probably use a washer in there to reduce the amount of wire. I have a 1" thick block of steel I'd put against the washer to keep everything flush and to weld against. Just have to watch the temps or the welds start to penetrate the block.

|

|

|

|

|

|

#4 |

|

Registered User

Join Date: Mar 2013

Location: Mesquite,Tx

Posts: 416

|

Re: Welding up larger holes...

A washer with a magnet on the backside works well, just sand off any coating the washer may have on it cad, zinc, ect.

|

|

|

|

|

|

#5 |

|

Registered User

Join Date: Mar 2012

Location: Lakes Region NH

Posts: 3,205

|

Re: Welding up larger holes...

^^^^ Good point! No Zinc / Cad!

|

|

|

|

|

|

#6 |

|

Registered User

Join Date: Jul 2007

Location: Toppenish, WA

Posts: 15,732

|

Re: Welding up larger holes...

Some outfit actually sells an assortment of plugs for doing just that but I'd either do the washer on the back thing or cut a plug out of a piece of scrap.

I bought a copper welding spoon similar to one of these http://www.ebay.com/sch/i.html?_trks...at=0&_from=R40 a while back but haven't tried it out yet. They act as a heat sink and the weld doesn't stick to them. Don't get carried away trying to fill the holes too fast and weld a bit and let it cool and weld a bit more rather than trying to weld up the whole hole at one time.

__________________

Founding member of the too many projects, too little time and money club. My ongoing truck projects: 48 Chev 3100 that will run a 292 Six. 71 GMC 2500 that is getting a Cad 500 transplant. 77 C 30 dualie, 454, 4 speed with a 10 foot flatbed and hoist. It does the heavy work and hauls the projects around. |

|

|

|

|

|

#7 |

|

Registered User

Join Date: Mar 2013

Location: Mesquite,Tx

Posts: 416

|

Re: Welding up larger holes...

$8 welding spoon at Harbor freight, I've have one also, but so far every hole I,ve welded up on the firewall I couldn't reach the other side with it, would help if you had a helper on the other side.

http://www.harborfreight.com/welding...oon-66785.html When I worked at a sheet metal shop years ago, there was plenty of slugs laying around by the punch press machine. Last edited by 1958Warrior; 10-15-2013 at 01:18 AM. Reason: add |

|

|

|

|

|

#8 |

|

Moderator

Join Date: Jul 2006

Location: Ozark, MO

Posts: 4,893

|

Re: Welding up larger holes...

Yeah, don't breathe zinc welding fumes, you won't like how puking your guts out and feeling like death, trust me on that one!!! The last thing you want is to drink milk but that's the quick remedy. We arc welded a bunch of galvanized embeds to galvanized decking and there was zero air movement. Learned that lesson the hard way, but I suspect a couple of washers would be fine so long as you keep your face away.

For holes, I pick up electrical box knock-outs off the ground on jobsites. It has gotten me a couple of funny looks but I just tell them "they taste great". There are 1" and 1.5" or 2" circles, just use a uni-bit to make the hole larger, hold it with a magnet and voila. As an electrician you know to bring you home a couple handfuls.

__________________

'86 GMC C30 Crew ~ '86 C20 Crew ~ '79 K15 Sierra Grande ~ '76 Blazer 2wd ~ '74K10 ~ '71 Cheyenne swb ~'50 3100 bagged ~ '80 Wife ~ Late model kids

|

|

|

|

|

|

#9 |

|

Registered User

Join Date: Jul 2007

Location: Toppenish, WA

Posts: 15,732

|

Re: Welding up larger holes...

That 7.99 HF welding spoon that 1958 Warrier posted sure looks exactly like several of those 16 to 20 something ones that I posted the link to earlier. Hummm buy a basket of them at HF and double the price on Ebay.

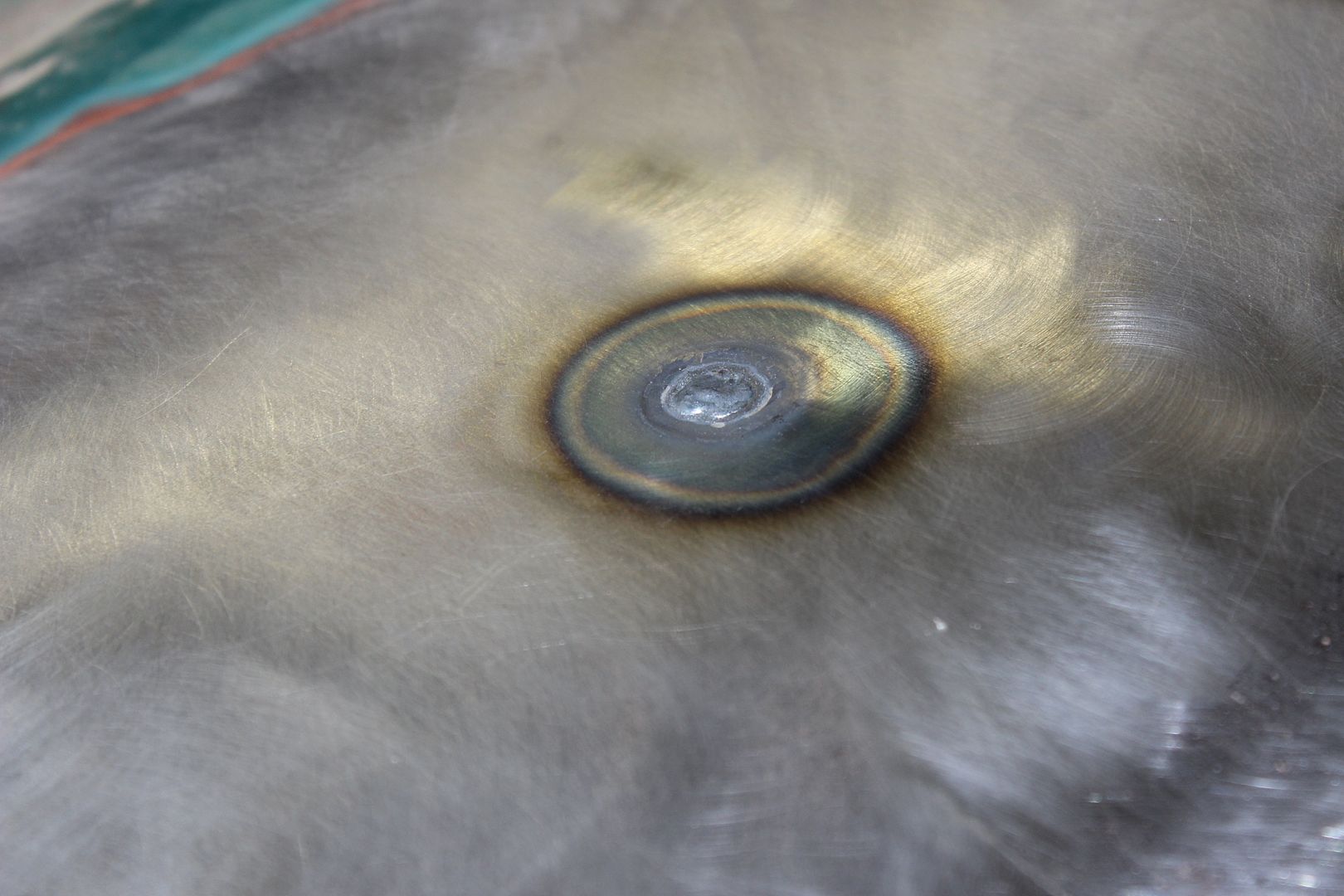

One of the do it yourself tools at the restoration shop that The Gene Winfield metal working class I went to had.  Gene welding a hole in the middle of a 57 Chevy door  The weld  Leevon, that reminded me, both of my brothers are journeymen electricians and I need to get them to save me a batch of those.

__________________

Founding member of the too many projects, too little time and money club. My ongoing truck projects: 48 Chev 3100 that will run a 292 Six. 71 GMC 2500 that is getting a Cad 500 transplant. 77 C 30 dualie, 454, 4 speed with a 10 foot flatbed and hoist. It does the heavy work and hauls the projects around. |

|

|

|

|

|

#10 |

|

Registered User

Join Date: Mar 2011

Location: Westchester, NY

Posts: 394

|

Re: Welding up larger holes...

Thanks for all the great feedback guys. Very helpful.

|

|

|

|

|

|

#11 |

|

Registered User

Join Date: Jan 2007

Location: tacoma wa.

Posts: 1,037

|

Re: Welding up larger holes...

If you have any plumber buds just flatten one end of some 3/4" copper pipe and that works killer plus you can make it any length you want. Great for reaching into quarter panels.

|

|

|

|

|

|

#12 |

|

Registered User

Join Date: Mar 2011

Location: Westchester, NY

Posts: 394

|

Re: Welding up larger holes...

Hey 55 dude thats exactly what I did! worked great and I could bend it whatever way was needed for the particular hole. Awesome.

|

|

|

|

|

|

#13 |

|

Registered User

Join Date: Jan 2007

Location: tacoma wa.

Posts: 1,037

|

Re: Welding up larger holes...

This I one of those tools that hangs around forever until you lend it out.

|

|

|

|

|

|

#14 |

|

Registered User

Join Date: Jun 2006

Location: Idaho

Posts: 8,800

|

Re: Welding up larger holes...

You can also take the copper pipe and flatten around a curve surface (pipe, socket, etc.) to use for curves. Do make sure you insulate the other end even a 12-18" length of copper can get hot fast even thru welding gloves. I have a variety of bimetal hole saws I use to cut filler for holes over 1/4". here is photo of the firewall with almost 50 holes in all sizes I filled. Odd shapes I just cut and grind with my small cutoff disc.

__________________

1959 Chevy Short Fleetside w/ 74 4WD drive train (current project) OrrieG Build Thread 1964 Chevelle Malibu w/ 355-350TH (daily driver) Helpful AD and TF Manual Site Old Car Manual Project |

|

|

|

|

| Bookmarks |

|

|