|

|

|

#1 |

|

Registered User

Join Date: Jan 2009

Location: league city, tx

Posts: 180

|

87 running lean?

My truck has lost power somewhere and its been a while since i tried to find out whats wrong. It doesnt have any check engine codes but lacks acceleration and responsiveness to the gas pedal. When I push on the pedal at any speed it sounds like the engine revs a little higher than its supposed to and especially if i let off the pedal after cruising at say 20 or 30 mph you can tell that it drops off too many RPMS. I would think its from a vacuum leak somewhere but i've already replaced the intake gaskets a year ago. i rechecked them about a month ago and still good. I also checked the little vacuum lines to the the TBI on both of their ends and they seem fine also. The MAP, IAC, and TPS are all less than a year old and check out fine also. I have been able to watch my live data via my laptop and interface cable. The single wire o2 stays lean at idle and then starts cycling once i rev it a little. then leans again. I don't think it cycles as fast or high and low as it should though. Seems to stay in the middle voltages like .3 to .7 not down to .1 and up to .8 or .9 like i've been told it should. The exhaust sounds kinda cruddy on acceleration which is how i KNOW something has to be wrong. I've had the catalytic converter checked, its good. No holes or anything in the exhaust. The engine has 67,000 original miles on it and has good compression across the board. Could the torque converter not be transferring as much power to the transmission or something like that? Could the AIR PUMP hoses and check valves be contributing? Bad injectors? the fuel pressure is 13 psi. Oh and the entire ignition system is recently replaced as well including the whole distributor. the EGR too. It is really bothering me when it looks like a good truck but it doesnt FEEL like one like it did three years ago. What the heck am I missing?

Last edited by jesdude7789; 07-03-2009 at 01:54 AM. |

|

|

|

|

|

#2 |

|

Registered User

Join Date: Jan 2009

Location: orangevale, ca

Posts: 3,626

|

Re: 87 running lean?

not too sure what to tell you besides do the cheap basics 1st. replace fuel filter, check for vaccum leaks w/ a can of carb. cleaner while its running, and check your work on the ignition...such as check plug wires at night with a bottle of windex while its running spray heavy down by the boots and look for pretty arc's.

__________________

"Dennis the Menace" 1978 Silverado (2wd, 1/2 ton, short bed)complete nut & bolt frame off restomod LQ9/4L80E MY LS SWAP/FRAME OFF BUILD BOOK 2006 TBSS way too much to list

|

|

|

|

|

|

#3 |

|

Registered User

Join Date: Jan 2009

Location: league city, tx

Posts: 180

|

Re: 87 running lean?

thanks menace!

I havent tried the windex thing but i'll check the vacuum again as well tonight. I hope i find something i missed before so it'll be done and run great again! It's the kind of thing that makes it not fun to drive.... which i will not stand for. |

|

|

|

|

|

#4 |

|

Registered User

Join Date: Mar 2008

Location: Salt Lake City UT

Posts: 441

|

Re: 87 running lean?

Pull a plug or two from each bank and read the electrode.

|

|

|

|

|

|

#5 |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: 87 running lean?

7789

What you are describing is a classic low fuel pressure symptoms. After 20+ years of service either fuel pump or the hose that connects pump to to the tank feed through are getting tired. TBI system is designed to operate at about 13 PSI, but will still function down to about 4-6 PSI. In other words. Check your fuel pressure at TB Check fuel filter //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

#6 |

|

Registered User

Join Date: Jul 2008

Location: Pennsville, New jersey (southern)

Posts: 143

|

Re: 87 running lean?

Go outside and Unhook the Coolant temperature sensor on the front of the engine, It is the one right near the water neck, the one that the computer uses.

When you unhook it, it should idle high and run better if thats the problem. If that sensor is unhooked it is tellling the computer that is -40~F and run full rich. Try that and see if it helps. Probably won't though rfmaster is probaly right though, If it is the original pump its probably tired and you MAY have a ripped Fuel Pressure regualtor diaghram. If so it will cause poor fuel pressure and it will stumble. Does your truck happen to have dual tanks? There may be a restriction in your fuel tank switchover, They were not suitable on a TBI truck from the factory due to the fact there so much more high pressure fuel systems, They simply took all the -86 Dual tank crap and mounted it on a 87 truck and the whole setup was very restrictive, expecially the return lines. If that valve is not opening all the way you would have fuel problems as well. Thats only if it has dual tanks. you'll get it figured out man. TBI's are easier than a quadrajet. Brandon

__________________

Mine- '91 GMC RCSB 2wd, 350tbi, 5 speed, 3.42 G80 -Dad/Me Projects/Toys 75 SWB Silverado Factory 454, Th400 87 SWB Silverado 305tbi, 700r4, 2.73's...17.4 @74mph a couple dodge cummins trucks. PLEASE DO NOT MESSAGE ME ABOUT FACTORY TACH DASHES, I AM NOT MY FATHER AND I KNOW VERY LITTLE ABOUT THEM. Thanks

Last edited by crossy's son; 07-03-2009 at 01:24 PM. |

|

|

|

|

|

#7 | |

|

Registered User

Join Date: Jan 2009

Location: league city, tx

Posts: 180

|

Re: 87 running lean?

Quote:

|

|

|

|

|

|

|

#8 |

|

Registered User

Join Date: Jan 2009

Location: orangevale, ca

Posts: 3,626

|

Re: 87 running lean?

sounds like cheap gas and/or the timings off. try bumping up the timing a bit... and like dan76 said check the plugs and see how they read.

__________________

"Dennis the Menace" 1978 Silverado (2wd, 1/2 ton, short bed)complete nut & bolt frame off restomod LQ9/4L80E MY LS SWAP/FRAME OFF BUILD BOOK 2006 TBSS way too much to list

|

|

|

|

|

|

#9 | |

|

Registered User

Join Date: Jan 2009

Location: league city, tx

Posts: 180

|

Re: 87 running lean?

Quote:

thanks

|

|

|

|

|

|

|

#10 |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: 87 running lean?

OK on fuel pressure - it may be worth checking with another gauge just be sure. The pinging that you are describing maybe due to re-formulated gas (E10). E10 has stoich mixture at 14.3 vs. 14.7 for normal gasoline formulation. It does not take that much but a persistent lean condition with E10 is a common problem for early EFI systems. Knock sensor is working over time in your case taking out timing when you really needed. Hence, sluggish throttle response.

Which software are you running WinALDL, Tuner-PRO?? Can you capture data logs? I wonder what your cross counts look like and BLM's - my guess they are all well above 128-132 region. //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

#11 | |

|

Registered User

Join Date: Jan 2009

Location: league city, tx

Posts: 180

|

Re: 87 running lean?

Quote:

|

|

|

|

|

|

|

#12 |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: 87 running lean?

I have used WinALDL extensively in the past - it is some what primitive, but it does the job. I use Tuner PRO -RT for bin file editing (aka tuning) I have not used it for data capture since I have modified my ECM with EBL conversion. EBL - that's another discussion all together.

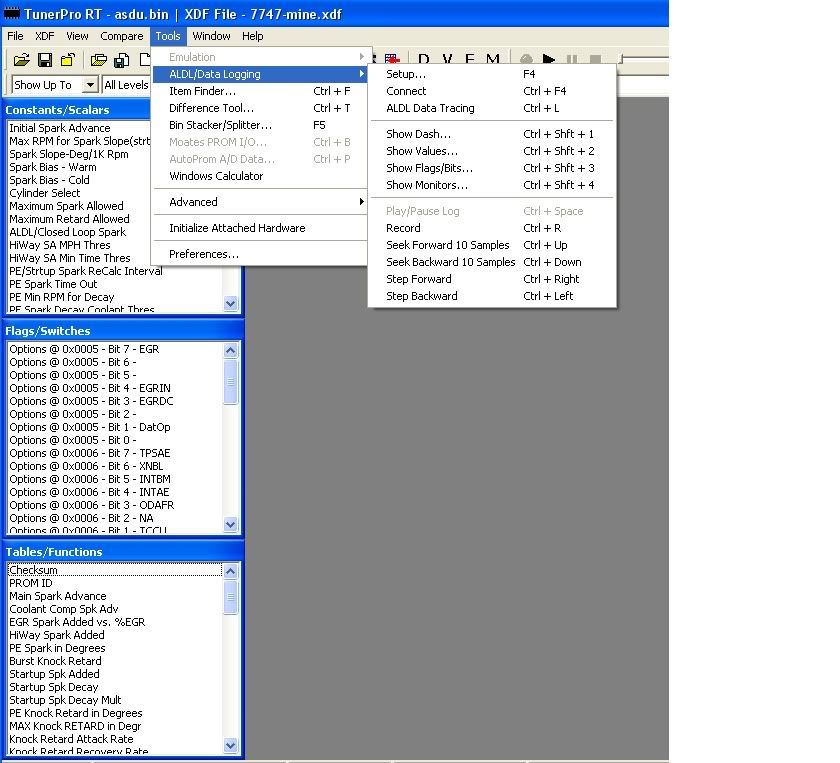

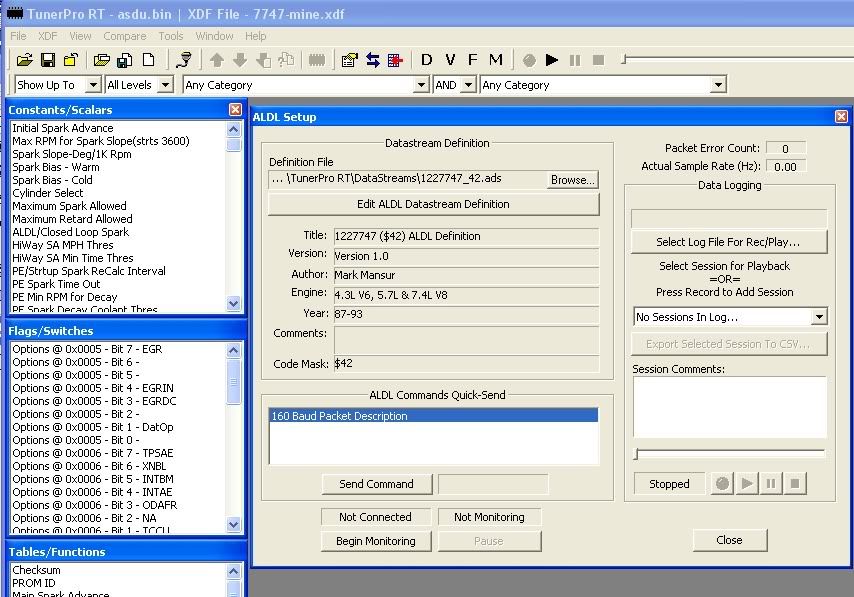

In your case capture the standard data stream which should contain the following critical sensor data: SENSOR:IAC SENSOR:Coolant Temp SENSOR:SPEED SENSOR:MAP SENSOR:RPM SENSOR:TPS SENSOR:INT SENSOR:O2 SENSOR:Battery Voltage SENSOR:Knock counter SENSOR:BLM SENSOR:rich / lean counter You'll have to define data log file see below:  Define file for capture (Select Log File For Rec/Play)

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

#13 |

|

Registered User

Join Date: Jan 2009

Location: league city, tx

Posts: 180

|

Re: 87 running lean?

ya thats how i've had it setup so far and just to look at the live data. Are you saying i should drive it around and record the data? or can i do it at idle and get enough info to determine whats wrong or being affected?

|

|

|

|

|

|

#14 |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: 87 running lean?

Ideally, Yes (you may need to get sig lighter to lapy DC-DC converter)

Do you you feel that you lost power at certain range of RPM's while you driving? Then you'll have to capture that engine performance data and the same operating conditions. Another thought - double check your spark plug routing and re-verify that spark wires are in good shape. One more than occasion I had engine hesitation that was eventually traced down to old spark wires arcing over. Just a thought (and does not cost anything). With engine running, in a dark garage, spray spark wires with a fine water mist. If you see blueish halo around wires or see engine stumble - you found that rascal. //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

#15 |

|

Registered User

Join Date: Jul 2008

Location: Pennsville, New jersey (southern)

Posts: 143

|

Re: 87 running lean?

Make sure you unhook the brown wire under the brake booster to advance the timing.

That really makes a difference on TBI trucks, advancing it 3* on my dad's 87 305 made a big difference in throttle response/power.

__________________

Mine- '91 GMC RCSB 2wd, 350tbi, 5 speed, 3.42 G80 -Dad/Me Projects/Toys 75 SWB Silverado Factory 454, Th400 87 SWB Silverado 305tbi, 700r4, 2.73's...17.4 @74mph a couple dodge cummins trucks. PLEASE DO NOT MESSAGE ME ABOUT FACTORY TACH DASHES, I AM NOT MY FATHER AND I KNOW VERY LITTLE ABOUT THEM. Thanks

|

|

|

|

|

|

#16 | |

|

Registered User

Join Date: Jan 2009

Location: league city, tx

Posts: 180

|

Re: 87 running lean?

Quote:

I am going to hook up to my laptop in a bit and check my live data and write it all down as it is set at idling conditions when hot and then i will post and see what ya'll think. oh ya and i will say that when i made a hard stop the other day at a light the engine stumbled and died and then started back up. And it is hard to start cold (four to six seconds)but usually easy when hot already(one or two seconds). I did the water mist on the spark plugs and wires though and did not see anything and the routing is correct. The cap, rotor, plugs and wires are all about two years old. ACCEL parts except for the wires, they are oreilly house brand

|

|

|

|

|

|

|

#17 |

|

Registered User

Join Date: Jan 2009

Location: league city, tx

Posts: 180

|

Re: 87 running lean?

Wow I think i just found the problem guys. I used my tuner pro and drove the truck around town a few miles til it was hot and everything, came back to the driveway and hooked up the laptop and the pics will show you my values at idle and then again at about 1000 rpm holding it steady. It looks like the coolant sensor is the culprit. 44 degrees celcius is only 110 farhenheit which is not what my temp gauge reads. it shows 180. I am on my way to getting a new sensor and hope it works!

Last edited by jesdude7789; 07-04-2009 at 03:47 PM. |

|

|

|

|

|

#18 |

|

Registered User

Join Date: Jan 2009

Location: orangevale, ca

Posts: 3,626

|

Re: 87 running lean?

right on man! hope it works out!!!

__________________

"Dennis the Menace" 1978 Silverado (2wd, 1/2 ton, short bed)complete nut & bolt frame off restomod LQ9/4L80E MY LS SWAP/FRAME OFF BUILD BOOK 2006 TBSS way too much to list

|

|

|

|

|

|

#19 |

|

Registered User

Join Date: Jan 2009

Location: league city, tx

Posts: 180

|

Re: 87 running lean?

well bad news....i replaced the coolant sensor and cleared the computer memory by disconnecting the battery for ten minutes. I just drove it home about 15 miles coming from a friends house. It seemed to accelerate better but i think that is because i reset the memory because when i got to the driveway and hooked up my laptop again to read the live data it still shows 47-48 degrees celcius! when i tested the resistance across the pins on the sensor it said 198 ohms which should translate to 190 degrees farhenheit or about 90 degrees celcius! Could the translating software be wrong on tuner pro or is there some weird wiring problem on my truck? Or is the ECM not translating the voltage properly? Plus the engine still sounds funny on acceleration like the wrong fuel ratio or timing not being advanced properly. Damn.

|

|

|

|

|

|

#20 | |

|

Registered User

Join Date: Jan 2009

Location: league city, tx

Posts: 180

|

Re: 87 running lean?

Quote:

I tried to data log with Winaldl but it doesnt seem to create a file or whatever so i cant look at my driving data. But i will say that my knock counter would go up a couple points any time i put my foot in the throttle so i do have a knocking problem and it is definitely going to retard the timing automatically. now the question is why is it knocking when my timing is set properly, my spark wires are good, and all my sensors seem to be operating properly? oh ya the screen shot doesnt show it because i reset the program accidently but my knock counter was up to 19 or 20 on a two mile trip during which i accelerated a little more than normal a few times. Last edited by jesdude7789; 07-05-2009 at 12:54 PM. |

|

|

|

|

|

|

#21 |

|

Registered User

Join Date: Jan 2009

Location: league city, tx

Posts: 180

|

Re: 87 running lean?

Ok now I'm getting pissed off because all my sensors work, today I checked my timing again with the brown wire unplugged and it's still dead on zero degrees just like it's supposed to be, and I checked my fuel pressure again and it is still 13 PSI! What the hell? My engine has to be knocking because the knock sensor is counting them and I can hear it when I try to accelerate. Anybody? Should I unplug the knock sensor and see how it runs?

|

|

|

|

|

|

#22 |

|

Senior Member

Join Date: May 2009

Location: Fort Worth, TX

Posts: 6,370

|

Re: 87 running lean?

check your tps voltage your readings showed idle voltage do it directly at the tps(with the engine off key on) with a voltmeter set to direct current between the black & blue wire should read below 1 volt at idle and slowley depress the throttle the volts should slowley increase to around 4.99 volts. can be as low as 4.00 volts as long as there is no dead spots in the reading ( a o reading or low voltage)

|

|

|

|

|

|

#23 |

|

Registered User

Join Date: Jan 2009

Location: league city, tx

Posts: 180

|

Re: 87 running lean?

I just went out and checked that. It works perfectly, all the way up 4.15 volts.

|

|

|

|

|

|

#24 |

|

Registered User

Join Date: Oct 2003

Location: OC CA

Posts: 1,374

|

Re: 87 running lean?

jes

Sorry, I was not able to return to the thread earlier - its fourth of July weekend. WinALDL was written for Win98 and WinY2K also works on XP. If you are running Vista you may run into some file write issues. A handful of knock counts during acceleration I would say is normal. I think the only way we are getting to the bottom of this is to get some data logging. In TunerPro-RT you can enable data conversion by changing operation function from multiply to use look up table. This should take care of conversion. This hesitation that you are experiencing could be due to a weak spark. Small hat HEI use external coil which are prone to fail over time. They tend to fail slowly over time, and go out completely when heat soaked. Typical symptoms - loss of power, hesitation, hard hot starts. The only way to verify coil is to have HV scope that can measure HV voltage pattern. Again, before blaming coil I would check all other ignition related parts - all wires, rotor, dizzy hat, and center contact. Sorry but I do not have any other thoughts at this time. As general rule I do not recommend mindless sensor swapping. //RF

__________________

"The Beast" 1975 Chevrolet C20 longbed 350/700R4! with 3inch body lift Dual Flowmasters Super 40's! TBI retrofit completed (2007-07-29)  New 383CID (+030) 08-304-8 9.5:1CR x36,005 (2012-12-17) |

|

|

|

|

|

#25 |

|

Registered User

Join Date: Jan 2009

Location: league city, tx

Posts: 180

|

Re: 87 running lean?

No need to apologize, I'm just happy this board exists and has cool people like you on it to help, thank YOU!

As for the coil, cap, rotor and wires, they were all replaced about two years ago. the coil cap and rotor are ACCEL brand and the wires were house brand since they did not have any accel brand wires. I know they are routed properly but I will say that I replaced the distributor a few months ago and in order to keep the module plugs toward the engine so the wires would reach I actually rotated the position of all the wires one terminal clockwise in order to rotate the housing and module. That way the module could be plugged in and the wires going to it were not stretched. I know i should have rotated the oil pump rod in order to keep everything like its supposed to be but I was frustrated and found an easier way i guess. I dont think that would matter tho as far as spark is concerned because its not like todays engines that need to KNOW where number one cylinder is and all that. Or am I wrong? I'm going to replace the wires soon anyway tho because I was never happy with house brand I want some nice RED performance wires to match my truck  Also I found the part in tuner pro to change to table lookup and i'm about to go hook it up and do some data logging. |

|

|

|

|

| Bookmarks |

|

|